9.2.1 The general

requirements for quality control are specified in ISO 25239-5.

9.2.2 Unless otherwise

specified in relevant parts of the Rules, the following production

tests will be required.

9.2.3 A production

test is required when there is a change in procedure, a change in

tooling, after equipment repairs or modifications, after deviation

from optimum parameters are detected, when defects are identified

by non-destructive testing, after continuous welding of every 100

m length during a single shift and with a maximum interval between

procedure tests of 8 hours. For butt welds the production tests are

to consist of 100 per cent visual examination, two face bend tests,

two root bend tests and one macro section. For thicknesses exceeding

12 mm, sets of face and bend tests may be replaced by side bend tests.

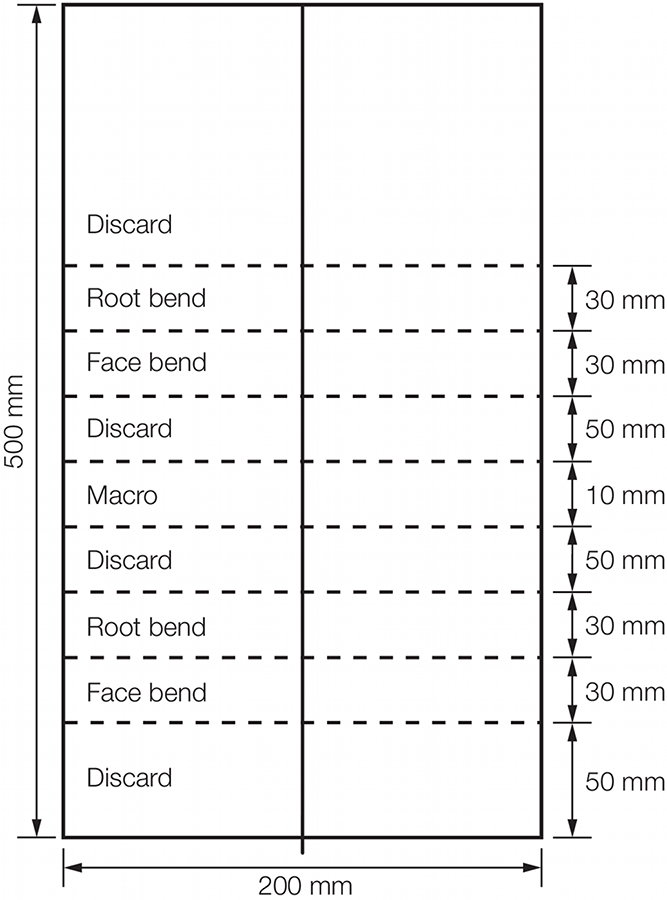

For test assembly, see

Figure 13.9.1 Production test assembly for

Friction Stir Welds. The production tests for other joint geometry are to

be agreed between the Surveyor and the fabricator.

Figure 13.9.1 Production test assembly for

Friction Stir Welds

9.2.4 As an automated

process, all essential variables are to be recorded by the FSW system.

The welding operator is responsible for ensuring that the system continues

to produce welds that are in compliance with the qualified procedure.

Surveyors are to be informed when the system exceeds the operating

parameters. Surveyors are periodically to review the welding records.

9.2.5 Production

welds are to be subject to 100 per cent visual examination by the

fabricator and be subject to random checking by the Surveyor.

9.2.6 Surface

and volumetric NDE testing is to be conducted on production welds

at a frequency of two per welded panel or one every 100 m of weld,

whichever is the greater.