Section

4 Design criteria

4.1 Allowable stress - Elastic failure

4.1.1 The

allowable stress, σa, is to be taken as the failure

stress of the component concerned multiplied by a stress factor, F,

which depends on the load case considered. The allowable stress is

given by the general expression:

where

|

σa

|

= |

allowable

direct stress, in N/mm2

|

|

τa

|

= |

allowable

shear stress, in N/mm2

|

|

F

|

= |

stress

factor |

|

σ, τ |

= |

failure

stress, in N/mm2.

|

4.1.2 The

stress factors, F, for steels in which

where

|

σy

|

= |

yield

stress of material, in N/mm2

|

|

σu

|

= |

ultimate

tensile stress of the material, in N/mm2

|

are given in Table 5.4.1 Stress factor, F.

Table 5.4.1 Stress factor, F

| Load Case

|

1

|

2

|

3

|

| Stress factor, F

|

0,60

|

0,85

|

0,6

|

4.1.3 For

steel with  the allowable stress is to be derived from the following

expression: the allowable stress is to be derived from the following

expression:

4.1.4 The

failure stress for the elastic modes of failure are given in Table 5.4.2 Failure stress.

Table 5.4.2 Failure stress

| Mode of failure

|

Symbol

|

Failure stress

|

| Tension

|

σt

|

1,0σy

|

| Compression

|

σc

|

1,0σcr

|

| Shear

|

τ

|

0,58σy

|

| Bearing

|

σbr

|

1,0σy

|

4.1.5 For

components subjected to combined stresses the following allowable

stress criteria are to be used:

-

σxx < Fσt

-

σyy < Fσt

-

τo < Fτ

-

σ =

(σxx

2 + σyy

2 - σxx σyy + 3τo

2)1/2 ≤

1,1Fσt

where

|

σxx

|

= |

applied

stress in x direction, in N/mm2

|

|

σyy

|

= |

applied

stress in y direction, in N/mm2

|

|

τo

|

= |

applied

shear stress, in N/mm2.

|

4.2 Allowable stress - Compression and bending members

4.2.1 The

allowable axial stress for compression members is to be taken as the

critical compressive stress, σcr, multiplied by the

allowable stress factor, F, as defined in Table 5.4.1 Stress factor, F.

4.2.2 For

members subjected to simple compression the critical compression stress

is given by the Perry-Robertson formula below:

4.2.3 For

members subjected to combined bending and compression the following

stress criteria are to be used:

where

|

σbx

|

= |

applied

bending stress about the X-X axis, in N/mm2

|

|

σc

|

= |

applied

compression stress, in N/mm2

|

|

σby

|

= |

applied

bending stress about the Y-Y axis, in N/mm2.

|

4.3 Allowable stress - Plate buckling failure

4.3.1 The

allowable stress is to be taken as the critical buckling stress σcb, σbb, or τb as appropriate

of the component concerned multiplied by the stress factor, F,

as defined in Table 5.4.1 Stress factor, F.

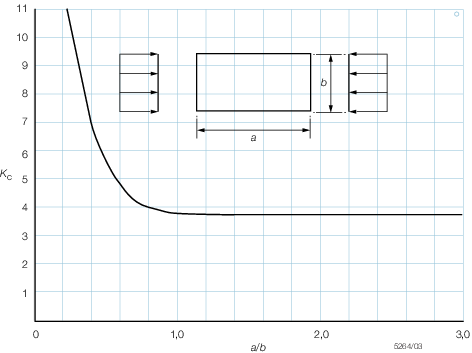

4.3.2 For

components subject to compression the critical buckling stress is

given by:

-

for σcb < 0,5σy

-

for σcb ≥ 0,5σy

where

|

σcb

|

= |

critical

compression buckling stress, in N/mm2

|

|

σy

|

= |

yield stress, in N/mm2 |

|

E

|

= |

Young's

modulus, in N/mm2

|

|

t

|

= |

plate

thickness, in mm |

|

b

|

= |

plate

width, i.e. normal to direction of stress, in mm. |

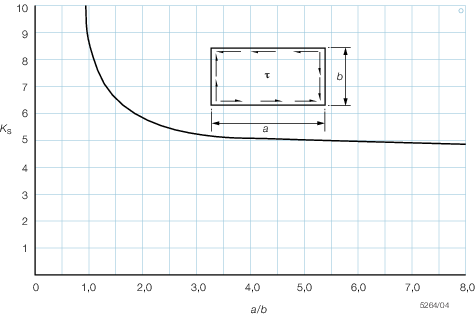

4.3.3 For

components subject to shear, the critical buckling stress is given

by:

-

for τb <

0,29σy

-

for τb ≥

0,29σy

where

|

τb

|

= |

critical

shear buckling stress, in N/mm2

|

|

σy |

= |

yield stress, in N/mm2 |

|

E

|

= |

Young's

modulus, in N/mm2

|

|

t

|

= |

plate

thickness, in mm |

|

b

|

= |

smallest

plate dimension, in mm. |

|

Ks |

= |

shear buckling constant, defined as follows

where

|

α |

= |

|

|

a |

= |

plate length corresponding to b |

The graphical representation of Ks is provided in Figure 5.4.2 Shear buckling constant Ks.

|

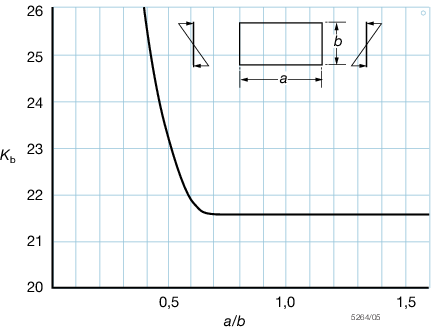

4.3.4 For

components subject to bending stress the critical buckling stress

is given by:

-

for σbb < 0,5σy

-

for σbb ≥ 0,5σy

where

|

σbb

|

= |

critical

buckling stress, in N/mm2

|

|

σy |

= |

yield stress, in N/mm2 |

|

E

|

= |

Young's

modulus, in N/mm2

|

|

t

|

= |

plate

thickness, in mm |

|

b

|

= |

plate

width, i.e. normal to direction of stress, in mm. |

|

Kb |

= |

bending buckling constant, defined as follows

for α ≥  :

for α <  :

where

|

α |

= |

|

|

a |

= |

plate length, i.e. in the direction of stress |

The graphical representation of Kb is provided in Figure 5.4.3 Bending buckling constant Kb.

|

4.3.5 For

components subject to combined compression and shear, the following

allowable stress criteria are to be met:

-

σc < Fσcb

-

τ < Fτb

-

|

τ |

= |

applied shear

stress, in N/mm2.

|

Figure 5.4.1 Compression buckling constant Kc

Figure 5.4.2 Shear buckling constant Ks

Figure 5.4.3 Bending buckling constant Kb

4.3.6 For

components subject to combined bending and shear, the following stress

criteria are to be met:

-

σb < Fσbb

-

τ < Fτb

-

Table 5.4.3 Values of Robertson Constant, a,

for various sections

| Type of section

|

Thickness of flange or plate, in mm

|

Axis of buckling

|

a

|

| Rolled section (universal

beams)

|

|

xx

|

2,0

|

| Roled H section (universal

columns

|

up to 40

|

xx

|

3,5

|

|

See Note 1

|

|

yy

|

5,5

|

|

|

over 40

|

xx

|

5,5

|

|

|

|

yy

|

8,0

|

| Welded plate or H sections

|

up to 40

|

xx

|

3,5

|

|

See Notes 1, 2 and 3

|

|

yy

|

5,5

|

|

|

over 40

|

xx

|

3,5

|

|

|

|

yy

|

8,0

|

| Rolled or H section with welded

flange cover plates

|

|

xx

|

3,5

|

|

See Notes 1 and 4

|

|

yy

|

|

|

|

|

xx

|

2,0

|

|

|

|

yy

|

|

| Welded box sections

|

up to 40

|

any

|

3,5

|

|

See Note 1, 3 and 4

|

over 40

|

any

|

5,5

|

| Rolled channel sections, rolled angle

sections and T-bars (rolled or cut from universal beam or column)

|

|

any

|

5,5

|

| Hot-rolled structural hollow

sections

|

|

any

|

2,0

|

| Rounds, square and flat bars

|

up to 40

|

any

|

3,5

|

|

See Note 1

|

Over 40

|

any

|

5,5

|

| Compound rolled sections (2 or more ,

H or channel sections, section plus channel, etc.)

|

|

any

|

5,5

|

| Two rolled angle, channel or

T-sections, back to back

|

|

any

|

5,5

|

| Two rolled sections laced or

battened

|

|

any

|

5,5

|

| Lattice strut

|

|

any

|

2,0

|

Note

1. For thickness between 40 mm and 50 mm

the value σcb, τb or σbb may be taken as the

average of the value for thicknesses less than 40 mm and the value for

thicknesses greater than 40 mm.

Note

2. For welded plate or H sections where

it can be guaranteed that the edges of the flanges will only be

flame-cut, a = 3,5 may be used for buckling about the y-y axis

for flanges up to 40 mm thick and , a = 5,5 for flanges over 40

mm thick.

Note

3. Yield strength for sections fabricated

from plate by welding reduced by 25 N/mm2.

Note

4. `Welded box sections' include those

fabricated from four plates, two angles or an or H section and two

plates but not box sections composed of two channels or plates with

welded logitudinals stiffeners.

|

Table 5.4.4 Value K, for different constraint

conditions

| Diagramatic

representation

|

Restraint conditions

|

K

|

|

Constrained against rotation and translation at

both ends

|

0,7

|

|

Constrained against rotation and translation at

one end and translation only at other end

|

0,85

|

|

Constrained against translation only at each

end

|

1,0

|

|

Constrained against rotation and translation at

one end and against rotation only at other end

|

1,5

|

|

Constrained against rotation and translation at

one end and free to rotate and translate at other end

|

2,0

|

4.3.7 For

components subject to combined bending and compression the following

allowable stress criteria are to be met:

-

σc < Fσcb

-

σb < Fσbb

-

4.3.8 For

components subject to combined compression, bending and shear, the

following allowable stress criteria are to be met:

-

σc < Fσcb

-

σb < Fσbb

-

τ < Fτb

-

4.4 Allowable stress - Joints and connections

4.4.1 For welded joints, the physical properties of the weld metal are considered

as equal to the parent metal. For full penetration butt welds, the allowable stress is

equal to the allowable stress of the parent material (see

Pt 3, Ch 5, 4.1 Allowable stress - Elastic failure).

4.4.2 For

fillet welds and welds subjected to shear, the allowable stresses

are reduced. Values of these reduced stresses are given in Table 5.4.5 Allowable stresses in welds,

N/mm2. Where, F,

is the stress factor, see

Table 5.4.1 Stress factor, F.

Table 5.4.5 Allowable stresses in welds,

N/mm2

| Type of weld

|

Allowable stress

|

| Direct

|

Shear

|

| Full penetration butt weld

|

1,0 Fσy

|

0,58 Fσy

|

| Fillet welds

|

0,7 Fσy

|

0,58 Fσy

|

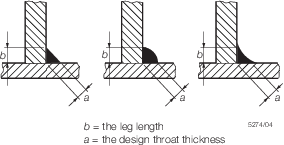

4.4.3 The

design stress in fillet welds is to be calculated on the `throat'

dimension of the weld. See

Figure 5.4.4 Fillet weld dimensions.

Figure 5.4.4 Fillet weld dimensions

4.4.4 The

strength of joints using pretensioned bolts to transmit shear and/or

tensile forces, e.g. high strength friction grip bolts, is to be determined

in accordance with an appropriate National or other acceptable code

or standard.

4.4.5 For

joints using precision bolts, defined as turned or cold finished bolts

fitted into drilled or reamed holes whose diameter is not greater

than the bolt diameter by more than 0,4 mm, the allowable stress due

to the externally applied load is given in Table 5.4.6 Allowable stresses for fitted

bolts.

4.4.6 Where

joints are subjected to fluctuating or reversal of load across the

joint the bolts are to be pretensioned by controlled means to between

70 and 80 per cent of their specified yield stress.

Table 5.4.6 Allowable stresses for fitted

bolts

| Type of

loading

|

Allowable

stress

|

| Load cases

|

Load case

|

| 1 and 3

|

2

|

| Tension

|

0,4 σy

|

0,54 σy

|

| Single shear

|

0,38 σy

|

0,51 σy

|

| Double shear

|

0,57 σy

|

0,77 σy

|

| Tension and shear

|

0,48 σy

|

0,64 σy

|

|

|

|

|

| Bearing

|

0,9 σy

|

1,2 σy

|

4.4.7 Black

bolts (ordinary grade bolts) are not to be used for primary joints

or joints subject to fatigue.

4.5 Deck plating thickness

4.5.1 The

deck plating thickness, t, for bridges and ramps is to

be adequate for the intended vehicle traffic and is to be calculated

with reference to the method described in Pt 3, Ch 4, 3.3 Deck plating.

4.6 Deflection criteria

4.6.1 In

Case 1 the deflection of the bridge or ramp between supports under

the applied load is to be limited to that given by the following expression:

where

|

L

|

= |

distance

between supports, in mm. |

4.6.2 For

cantilevered sections of bridges and ramps the deflection is to be

limited to  mm mm

where

|

L

|

= |

is

the length of the cantilevered section. |

4.7 Hoisting and slewing arrangements

4.7.1 Where

chains are used as part of the hoisting or slewing arrangement they

are to have a minimum safety factor of 4,0.

4.7.2 Where

wire ropes are used as part of the hoisting or slewing arrangement

the safety factor is to be determined as:

where

|

SF

|

= |

minimum

safety factor required |

|

W

|

= |

weight

of the ramp in tonnes (for ramps which are unloaded during manoeuvring) |

The actual design safety factor is to be not less than four

and need not be greater than five.

4.8 Locking arrangements

4.8.1 Where

bridges and ramps are raised or lowered in the unloaded condition

and then pinned or locked off to support both the dead weight and

vehicle loads, the pins (or locking device) are to be adequate for

the worst loading derived from Case 1 and are to satisfy the allowable

stress criteria of Pt 3, Ch 5, 4.1 Allowable stress - Elastic failure,Pt 3, Ch 5, 4.2 Allowable stress - Compression and bending members ,Pt 3, Ch 5, 4.3 Allowable stress - Plate buckling failure ,Pt 3, Ch 5, 4.4 Allowable stress - Joints and connections.

4.9 Safety restraints

4.9.1 Where

a bridge or ramp is retained in position by a single articulated mechanical

connection a suitable means is to be provided to prevent the complete

detachment of the bridge or ramp from the support in the event of

failure of the joint.

4.9.2 Chains

or wire ropes used for this purpose are to take due account of the

kinetic energy developed by the falling structure and are to have

a safety factor of at least two.

4.9.3 To

prevent movement and consequent failure, pins for all primary hinges

and articulations are to be locked in position by adequate keep plates,

castellated and wired nuts, end cover plates or other suitable means.

4.10 Deck gradients and transitions

4.10.1 The

gradients of bridges and ramps are in general not to exceed a slope

of 1 in 10 during normal operation with ships at lowest or highest

freeboard at Mean Low or High Water Spring Tides respectively. Additionally,

a maximum slope of 1 in 8 will be permitted for Lowest and Highest

Astronomical Tides.

4.10.2 Changes

in bridge or ramp gradients and transitions are to take account of

ground clearance of the vehicles using the linkspan throughout the

operational range.

|