Section

12 Closing arrangements for deck and shell

12.1 Hatch covers

12.1.1 The requirements

are given for single panel, steel plated or equivalent, cargo hatch

covers, stiffened longitudinally and secured around the perimeter

by manual ‘kestner’ type, clamping devices. The hatch

covers are, in general, lifted by a travelling gantry deck crane.

12.1.2 For hatch

covers of other types and designs, the scantlings will be specially

considered.

12.1.4 Where

hatch covers are manufactured from material other than steel, then

direct equivalency to these requirements is to be complied with.

12.2 Means to ensure weathertightness

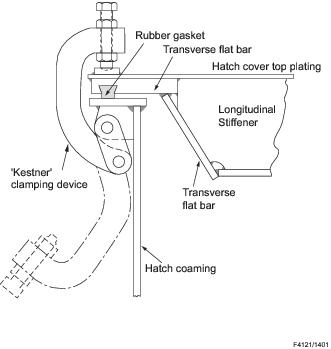

12.2.1 The typical

weathertight sealing arrangement, in general, is achieved by a rubber

gasket on the hatch cover, compressed onto the top rail of the hatch

coaming, see

Figure 4.12.1 Typical hatch cover sealing arrangement.

Figure 4.12.1 Typical hatch cover sealing arrangement

12.2.4 The clamping

devices may be cast or fabricated.

12.3 Plating

12.3.1 The thickness

of the plating of the hatch cover is to be not less than 6,0 mm or  , whichever is greater, where s is the spacing

of longitudinals or stiffeners (shorter panel dimension), in mm. , whichever is greater, where s is the spacing

of longitudinals or stiffeners (shorter panel dimension), in mm.

12.4 Stiffeners

12.4.1 The scantlings

and strength criteria of the hatch cover stiffeners are to be as follows:

-

For ships 110 m in length and greater, calculated with design loading

for Position 1, not less than 11,97 kN/m2and for Position 2, not less

than 9,52 kN/m2, with an equivalent design head of 1,70 m and 1,35 m

respectively. The product of the maximum stress thus calculated and the factor of

4,25 shall not exceed the minimum tensile strength of the material, with the

maximum permissible deflection limited to not more than 0,0028 times the span.

-

For ships 24,1 m in length, the design loading on the hatch cover for

Position 1, may be 9,52 kN/m2 and for Position 2, may be 7,16

kN/m2 with an equivalent design head of 1,35 m and 1,01 m

respectively.

-

For intermediate

lengths the values shall be obtained by linear interpolation.

The maximum permissible shear stress is not to exceed 108/k

Nmm2.

12.4.2 Additional

stiffening members are generally also arranged, so as to provide suitable

rigidity to the hatch cover during the lifting operation.

12.5 Hatch coamings

12.5.1 Hatch coamings, either vertical at sides or ends or sloped at sides, are to

have a minimum thickness of 11 mm. The top edge is to be stiffened by a horizontal flat

bar with a minimum width of 75 mm.

12.5.2 Additional support is to be given to the hatch coamings by the fitting of

stays not more than 3 m apart. Each stay is to have a minimum thickness of 9,5 mm and is

to be suitably supported under the deck.

12.5.3 Where

hatch side coamings are sloped, the support arrangements of the coaming

will be specially considered.

12.5.4 The deck

plating is generally to extend inside the coamings.

12.5.5 A hatch

end beam is to be arranged under the hatch end coaming. Transverse

continuation brackets are to be arranged outboard of the hatches in

line with the hatch end beam.

12.5.6 The height

of the coamings above the upper surface of the deck, for hatchways,

closed by covers secured weathertight by clamping devices shall be:

Position 1 (as defined in Ch 4, 1.4 Definitions 1.4.6)

– 460 mm

Position 2 (as defined in Ch 4, 1.4 Definitions 1.4.6) – 300 mm

12.5.7 Where

coamings of less height than required by 12.5.6 are fitted, the agreement

of the Canadian Authority shall be obtained and the requirements of Pt 3, Ch 11, 5.1 General 5.1.3 of the Rules

for Ships shall apply.

12.6 Engine room gangway doors

12.6.2 These

requirements cover cargo and service doors in the side shell plating

in way of the engine room.

12.6.3 Engine

room gangway doors shall be so fitted as to ensure tightness and structural

integrity commensurate with their location and the surrounding structure.

12.6.4 Without

the special agreement of the Canadian Authority, the lower edge of

the door openings shall not be below a line drawn parallel to the

freeboard deck at side, that has its lowest point at the upper edge

of the uppermost load line.

12.6.5 When

the doors open inward, the structure and closing arrangements will

be specially considered.

12.6.6 Where

an additional opening is arranged in the gangway door, then suitable

closing arrangements are to be fitted.

12.6.8 Doors

are to be fitted with an adequate means of closing, securing and support

so as to be commensurate with the strength and stiffness of the surrounding

structure. The hull supporting structure in way of the doors is to

be suitable for the same design loads and design stresses as the securing

and supporting devices. Where packing is required the packing material

is to be of a comparatively soft type and the supporting forces are

to be carried by the steel structure only. The maximum design clearance

between securing and supporting devices is generally not to exceed

3 mm.

|