Section

11 Double skin structure

11.1 General

11.1.1 This

Section covers the arrangements and requirements for transversely

and longitudinally framed side shell structures of double skin ships.

11.1.3 The side

shell may be transversely or longitudinally framed. The longitudinal

bulkheads are in general to have the same framing system as the shell.

11.2 Transverse framing

11.2.1 The lower

ends of side frames and stiffeners of longitudinal bulkheads may overlap

the floors or otherwise be connected to the floors or tank top by

means of brackets. At their upper ends, side frames and bulkhead stiffeners

are to be interconnected by means of brackets, see

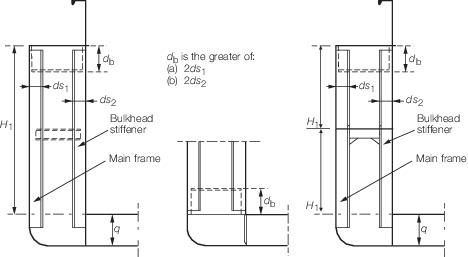

Figure 1.11.1 Frame arrangement (transverse framing).

11.2.2 In addition

to the frames, plate webs are to be fitted spaced not more than 8

m apart, see also

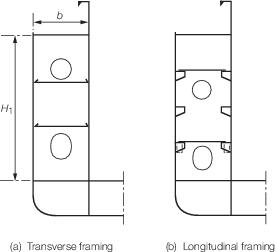

Figure 1.11.2 Arrangement of plate webs. Manhole openings are to be provided in the plate

webs to allow for inspection. Horizontal stiffeners are to be fitted

to the plate webs, spaced not more than twice the frame spacing apart.

Plate webs with large access holes are to be additionally stiffened

and their scantlings are to be verified by direct calculations. The

scantlings of truss-type web frames, replacing plate webs and composed

of rolled or built sections, are to be determined by direct calculation.

11.2.3 Alternatively,

plate webs in accordance with Pt 4, Ch 1, 11.2 Transverse framing 11.2.2 may

be fitted at every frame.

Table 1.11.1 Double skin structure (General

requirements)

| Item

|

Parameter

|

Requirement

|

| (1)

|

Shell frames

|

Modulus

|

cm3 cm3

|

| (2)

|

Vertical stiffeners on longitudinal

bulkhead

|

Modulus

|

|

| (3)

|

Brackets under deck

|

Depth

|

db as shown in

Figure 1.11.1 Frame arrangement (transverse framing)

|

|

|

|

Thickness

|

mm mm

|

|

|

|

Flange width

|

mm mm

|

| Longitudinal framing systems

|

| (4)

|

Shell longitudinals

|

Modulus

|

cm3, see Note 1 cm3, see Note 1

|

| (5)

|

Horizontal stiffeners on longitudinal

bulkhead

|

Modulus

|

cm3, see Note 1 cm3, see Note 1

|

| (6)

|

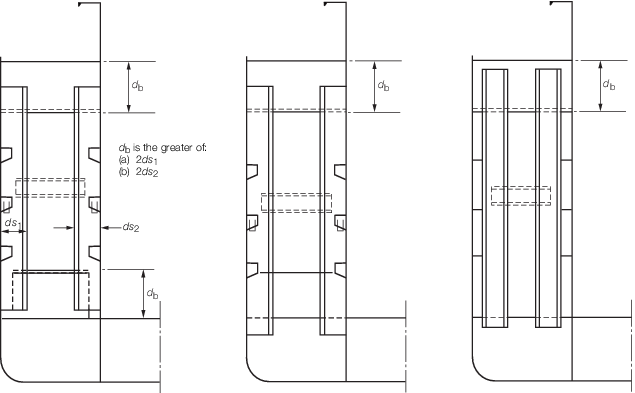

Web frames at shell, see

Figure 1.11.3 Arrangement for web frames

|

Modulus

|

cm3 cm3

|

| (7)

|

Web frames on longitudinal bulkhead,

Figure 1.11.3 Arrangement for web frames

|

Modulus

|

|

| (8)

|

Bracket under deck

|

Depth

|

dbas shown in Figure 1.11.1 Frame arrangement (transverse framing)

|

|

|

|

Thickness

|

mm mm

|

|

|

|

Flange width

|

m m

|

| Transverse and longitudinal framing systems

|

| (9)

|

Plating of longitudinal bulkhead,

see Notes 2 and 3

|

Thickness

|

|

| (10)

|

Plate webs, see

Figure 1.11.2 Arrangement of plate webs

|

Thickness

|

The greater of

mm mm

|

| (11)

|

Horizontal stiffeners on webs

|

Width

|

mm mm

|

|

|

|

Thickness

|

thickness plate webs thickness plate webs

|

| Symbols

|

| L,

B, D, T, S, s, t, k,

Z and Iare as defined in Pt 4, Ch 1, 1.5 Symbols and definitions 1.5.1

|

|

hs

|

= |

hde + ht but not less than 2,0

m |

|

hde

|

= |

distance of longitudinal to the deck at side, in

metres |

|

|

= |

0,50 for deep tanks but not less than the distance to

the top of the overflow |

|

s1

|

= |

spacing between horizontal stiffeners, in metres |

|

sd

|

= |

stiffener spacing or width of double skin, whichever

is the smaller |

|

|

ts

|

= |

thickness of side shell, in mm |

|

L1

|

= |

L, but is to be taken as not less than 50 m nor more than

100 m |

|

Sb

|

= |

spacing of plate webs, in metres |

|

h4 |

= |

ho + 0,5 b1 |

| = |

the greater of the distance, in metres, from the middle of the

effective length to the top of the cargo or |

| = |

1,5 m |

| = |

whichever is the greatest |

|

hO |

= |

the vertical distance, in metres, from the mid-point of span of

the stiffener to the highest point of the tank including

hatchway |

|

b1 |

= |

the horizontal distance, in metres, from the centre line to the

hatchway in way of the cargo hatch |

|

T1

|

= |

D – q, but need be taken not greater than T +

0,4 – q for Zone 3, T + 0,7 – q m for Zone 2, T + 1,0 – q m

for Zone 1, in metres |

|

Zf

|

= |

modulus of frame, in cm3

|

|

Zl

|

= |

modulus of side shell longitudinal, in cm3

|

|

Zw

|

= |

modulus of web frame, in cm3

|

|

Note

1. The web thickness of longitudinals is

not to be less than 7 mm.

Note

2. For bulk carriers it is recommended to

add 3 mm to the thickness of the lower edge of the bulkhead over a

height of about 250 mm above the inner bottom.

Note

3. The thickness of the upper strake of

the longitudinal bulkhead may require to be increased to satisfy the

hull girder bending stress criteria in Pt 3, Ch 4 Longitudinal Strength

|

Figure 1.11.1 Frame arrangement (transverse framing)

11.3 Longitudinal framing

11.3.1 Longitudinals

on shell and longitudinal bulkheads are to be supported by web frames,

spaced not more than 2,5 m apart, and efficiently connected thereto.

Figure 1.11.2 Arrangement of plate webs

Figure 1.11.3 Arrangement for web frames

11.3.2 Web frames

are to be fitted in line with plate floors and are generally to be

constructed as indicated in Figure 1.11.3 Arrangement for web frames.

The lower ends of the web frames may overlap the floors or are otherwise

to be connected to the floors or tank top by means of brackets. At

their upper ends, web frames are to be interconnected by means of

brackets, see also

Figure 1.11.3 Arrangement for web frames.

11.3.3 In addition

to the web frames as required by Pt 4, Ch 1, 11.3 Longitudinal framing 11.3.2,

plate webs are to be fitted not more than 8 m apart, see also Fig. Figure 1.11.2 Arrangement of plate webs(b). Manhole openings are to

be provided in the plate webs to allow for inspection. Horizontal

stiffeners are to be fitted to the plate webs spaced not more than

twice the frame spacing apart. Plate webs with large access holes

are to be additionally stiffened and their scantlings are to be verified

by direct calculations.

11.4 Longitudinal bulkhead

11.4.2 Where

the longitudinal bulkhead is not connected to the bottom shell but

supported by the bottom floors, vertical stiffeners are to be fitted

to the floors and connected to the inner bottom plating in line with

the longitudinal bulkhead.

11.4.3 The ends

of the longitudinal bulkheads are to be well scarfed into the ship's

fore and aft structure.

11.5 Watertight sub-division

11.5.1 It is

recommended that Owners consider subdividing the space between side

shell and longitudinal bulkhead such that the ship remains afloat

when one of the compartments becomes flooded.

11.5.2 For ships navigating on the Rhine or on European waterways with an overall

length greater than 110 m, compliance with damage stability requirements are mandatory

in accordance with the European Standard laying down Technical Requirements for Inland

Navigation vessels (ES-TRIN).

|