Section

2 Decks loaded by wheeled vehicles

2.1 General

2.1.1 Where it

is proposed either to stow wheeled vehicles on the deck or to use

wheeled vehicles for cargo handling, the deck and supporting structure

are to be designed on the basis of the maximum loading to which they

may be subjected in service. Where applicable, hatch covers are to

be similarly designed. In no case, however, are the scantlings to

be less than would be required for a deck in this location.

2.2 Loading

2.2.1 Details

of the deck loading resulting from the proposed stowage or operation

of vehicles are to be supplied by the Shipbuilder. These details are

to include the wheel load, axle and wheel spacing, tyre print dimensions

and type of tyre for the vehicles.

2.2.2 For design

purposes where wheeled vehicles are to be used for cargo handling,

the deck is to be taken as loaded with a normal head of cargo, except

in way of the vehicle.

2.3 Deck plating

2.3.1 The deck

plating thickness is to comply with Table 9.2.1 Loading by wheeled

vehicles.

Table 9.2.1 Loading by wheeled

vehicles

| Item

|

Parameter

|

Requirements

|

|

(1) Deck plating

|

Plating thickness

|

|

t

|

= |

+ 1,5 mm, see Note + 1,5 mm, see Note |

|

|

(2) Deck beams, longitudinals and stiffeners when fork lift

trucks are to be used

|

Section modulus

|

|

Z

|

= |

(0,375K

1

Ple + 1,25K

2

hsle

2 )k cm3

|

|

|

(3) Deck beams, longitudinals and stiffeners for decks

permanently used for vehicles, in association with a value of h

which need not exceed 2,5 m

|

Section modulus

|

|

Z

|

= |

(0,536K

1

Ple + 1,25K

2

hsle

2)k cm3

|

|

|

(4) Deck girders and transverses

|

Section modulus

|

|

| Symbols

|

|

b

|

= |

mean width of plating supported by a deck girder or

transverse, in metres |

|

s

|

= |

spacing of stiffeners, in metres |

|

t

|

= |

thickness of plating, in mm |

K

1 and K

2 are factors given in Table 9.2.4 Values of K

1 and K

2

|

P

|

= |

total weight of the vehicle divided by the number of

axles. Where the distribution of weight is not uniform, P is

to be taken as the maximum axle load. For fork lift trucks the

total weight is to be applied to one axle, in tonnes |

|

|

|

Table 9.2.2 Corrected patch load

calculation

| Symbols

|

Expression

|

a, s, u and v

are as defined inFigure 9.2.1 Tyre print load stress

factor

|

P

1

|

= |

corrected patch load, in tonnes |

|

Φ1

|

= |

patch aspect ratio correction factor |

|

Φ2

|

= |

panel aspect ratio correction factor |

|

Φ3

|

= |

wide patch load factor |

|

|

|

Φ1 |

= |

|

|

v

1 = v, but ≤ s

u

1 = u, but ≤ a

|

|

|

for u ≤ (a - s)

|

|

|

= |

|

|

for a ≥ u >

(a – s)

|

|

|

= |

0,77

|

|

for u > a

|

|

|

for v < s

|

|

|

= |

0,6 + 0,4 + 0,4 |

|

for 1,5 >  > 1,0 > 1,0

|

|

|

= |

1,2

|

|

for  ≥ 1,5 ≥ 1,5

|

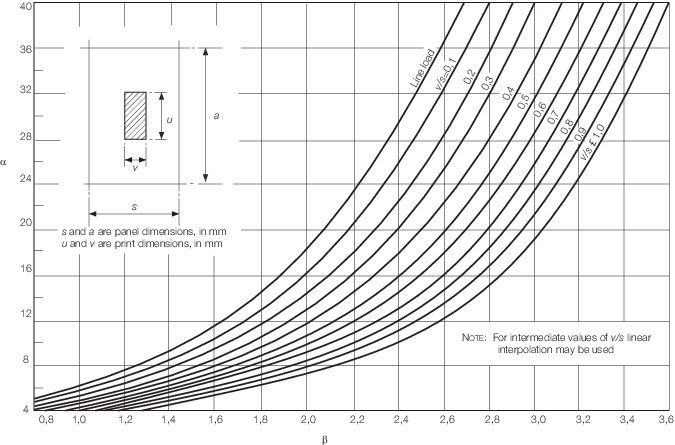

Figure 9.2.1 Tyre print load stress

factor

Table 9.2.3 Approximate deck thickness for

fork lift trucks

| Capacity of fork lift,

in tonnes

|

(max.) (max.)

|

| 1,0

|

0,085

|

| 5,0

|

0,045

|

| 10,0

|

0,037

|

| 15,0

|

0,034

|

| 20,0

|

0,032

|

Table 9.2.4 Values of K

1 and K

2

|

K

1

|

K

2

|

| 0,1

|

15,4

|

1,89

|

| 0,2

|

14,6

|

1,845

|

| 0,3

|

13,35

|

1,730

|

| 0,4

|

11,8

|

1,55

|

| 0,5 and greater

|

10,1

|

1,30

|

| *Outer

wheel to outer wheel on axles with multiple wheel arrangements

|

2.3.3 Where it

is proposed to use vehicles having steel wheels, deck thicknesses

will be specially considered.

2.3.4 Where transversely

framed decks contribute to the hull girder strength or where secondary

stiffening is fitted perpendicular to the direction of vehicle lanes,

the thickness, t, derived from Table 9.2.1 Loading by wheeled

vehicles is to be increased by 1,0 mm.

2.3.5 Where decks

are designed for the exclusive carriage of unladen wheeled vehicles,

the deck plate thickness, t, derived from Table 9.2.1 Loading by wheeled

vehicles may be reduced by 0,75

mm.

2.3.6 Where it

is proposed to carry tracked vehicles, the patch dimensions may be

taken as the track print dimensions and P

w is

to be taken as half the total weight of the vehicle. The deckplate

thickness, t, derived from Table 9.2.1 Loading by wheeled

vehicles is to be increased by 0,5 mm. Deck fittings in way of

vehicle lanes are to be recessed.

2.3.7 If wheeled

vehicles are to be used on insulated decks or tanktops, consideration

will be given to the permissible loading in association with the insulation

arrangements and the plating thickness.

2.4 Deck beams and longitudinals

2.4.1 The section

modulus, Z, of deck beams or longitudinals is to be not

less than that required for a deck in this location, nor less than

the following:

-

For general purpose

cargo decks where fork lift trucks are to be used, the value of Z is

to be as in Table 9.2.1 Loading by wheeled

vehicles.

-

For permanent vehicle

decks in association with a value of h which need not

exceed 2,5 m, Z is to be as in Table 9.2.1 Loading by wheeled

vehicles.

-

For decks designed

for the carriage of wheeled vehicles only:

that required to satisfy the most severe arrangement of print

wheel loads on the stiffener in association with a bending stress

of 100 N/mm2 (10,2 kgf/mm2) assuming 100 per

cent end fixity.

2.5 Deck girders and transverses

2.5.2 Where the

member supports point loads, with or without the addition of uniformly

distributed load, the section modulus is to be based on a stress of

123,6 N/mm2 (12,6 kgf/mm2) assuming 100 per

cent end fixity.

2.5.3 Where it

is proposed to carry tracked vehicles, the total weight of the vehicle

is to be taken when determining the section modulus of the transverse

at the top of a ramp or at other changes of gradient.

2.6 Heavy and special loads

2.6.1 Where heavy

or special loads, such as machinery transporters or large tracked

vehicles are proposed to be carried, the scantlings and arrangements

of the deck structure will be individually considered.

|