Section

2 Scantlings of bulkheads

2.1 Watertight and deep tank bulkheads

2.1.2 Stiffening

members of horizontal bulkheads of tanks may be supported by girders

or a system of girders and pillars.

Table 7.2.1 Watertight and deep tank bulkhead

scantlings

| Item and

requirement

|

Watertight

bulkheads

|

Deep tank

bulkheads

|

|

(1) Plating thickness for plane and symmetrically corrugated

bulkheads

|

The greater of the following:

|

t

|

= |

4w

+ 0,5 mm + 0,5 mm |

or

|

The greater of the following:

|

t

|

= |

4w  + a mm + a mm |

or

|

t

|

= |

5 mm for oil tanks and fresh water tanks |

|

t

|

= |

5,5 mm for water ballast tanks, see Note 3 |

|

|

(2) Modulus of rolled and built stiffeners, swedges and

symmetrical corrugations

|

|

Z

|

= |

5 × k × s × le

2 × h

4 cm3

|

|

|

Z

|

= |

6 × k × s × le

2 × h

4 × ρ cm3

|

|

|

(3) Stringers or webs supporting vertical or horizontal

stiffening

|

|

|

|

(a) Modulus

|

|

Z

|

= |

7 × k × h

4 × S × le

2 cm3

|

|

|

Z

|

= |

8,5 × k× h

4 × S × le

2 × ρ cm3

|

|

|

(b) Inertia

|

-

|

|

|

= |

cm4 cm4

|

|

|

(4) Pillars in tanks, cross-sectional area

|

-

|

|

| Symbols

|

|

t

|

= |

thickness of plating, in mm |

|

s

|

= |

spacing of stiffeners, corrugations, girders or webs,

in metres |

|

ρ |

= |

specific gravity of liquid carried in the tank, but

is to be taken as not less than 1 |

|

a

|

= |

1 mm for oil and fresh water tanks and 1,5 mm for

water ballast tanks |

|

h

4

|

= |

load head, in metres, measured vertically as follows,

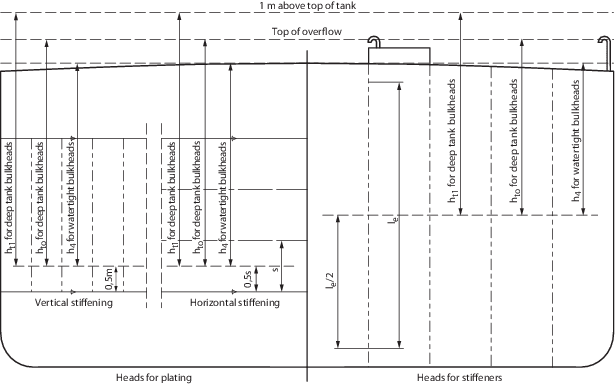

see also

Figure 7.2.1 Heads for watertight and deep tank bulkheads

- (a) for vertically stiffened watertight bulkhead plating –

the distance from a point 0,5 m above the lower edge of the

plate to the top of the bulkhead

- (b) for horizontally stiffened watertight bulkhead plating

- the distance from the middle of the first panel above the

lower edge of the plate to the top of the bulkhead

- (c) for vertically stiffened deep tank bulkhead plating -

the distance from a point 0,5 m above the lower edge of the

plate to a point 1 m above the top of the tank, or to the top

of the overflow, whichever is the greater

- (d) for horizontally stiffened deep tank bulkhead plating -

the distance from the middle of the first panel above the

lower edge of the plate to a point 1 m above the top of the

tank, or to the top of the overflow, whichever is the

greater

- (e) for watertight stiffeners or girders, the distance from

the middle of the effective length to the top of the

bulkhead

- (f) for deep tank bulkhead stiffeners or girders, the

distance from the middle of the effective length to a point 1

m above the top of the tank, or to the top of the overflow,

whichever is the greater

|

|

P

|

= |

load supported by the pillars, in tonne f |

|

Note

1. For rolled or built stiffeners with

flanges for face plates the web thickness is to be not less than  of the web depth, whilst for flat bar stiffeners

the web thickness is to be not less than of the web depth, whilst for flat bar stiffeners

the web thickness is to be not less than  of the web depth. of the web depth.

Note

3. Bulkhead plating from the bottom to

0,1 m above ceiling in holds is to be at least 6 mm in thickness.

|

Figure 7.2.1 Heads for watertight and deep tank bulkheads

2.1.3 Pillars

in tanks are not to be of hollow construction and are to be bracketed

at top and bottom. Scantlings and welding of the brackets are to take

account of the maximum tensile force on the pillar.

2.1.5 Fuel oil

carried in tanks is to have a flash point not less than 55°C.

Where tanks are intended for liquid fuels of a special nature, the

scantlings and arrangements will be considered in relation to the

nature of the fuel, see also

Pt 3, Ch 12, 2 Rudders.

2.1.6 If cargo

is carried in a compartment adjacent to a fuel oil tank which may

be heated, the compartment side of the bulkhead or deck is to be insulated,

or equivalent arrangements provided.

2.1.7 Where watertight

bulkhead stiffeners are cut in way of watertight doors, the opening

is to be suitably framed and reinforced, and the adjacent stiffeners

are to be increased in proportion to the greater spacing. Where the

stiffener spacing is locally increased on account of watertight doors,

the stiffeners at the sides of the doorways are also to be increased.

Recesses in bulkheads are generally to be so stiffened as to provide

strength and stiffness equivalent to the requirements for the bulkhead.

2.2 Non-watertight bulkheads

2.2.1 The scantlings

of non-watertight bulkheads acting as hull supporting structure are

to comply with the requirements of Table 7.2.2 Non-watertight bulkheads. Where the bulkhead stiffeners support deck girders,

transverses or pillars over, they are also to comply with the requirements

of Table 7.2.3 Bulkhead stiffeners supporting

concentrated loads.

Table 7.2.2 Non-watertight bulkheads

| Parameter

|

Requirements

|

| (1) Plating thickness for plane

bulkheads

|

The greater of the following:

t = 4 × k × s ×  mm mm

or

t = 3,5 mm

|

| (2) Modulus of rolled and built

stiffeners and swedges

|

Z = 4 × k × s ×

le

2 × h

4 + 3 cm3

|

|

|

Table 7.2.3 Bulkhead stiffeners supporting

concentrated loads

| Parameter

|

Requirements

|

| (1) Cross-sectional area for rolled,

built or swedged stiffeners, supporting girders, transverses, pillars or

concentrated loads

|

see Note

|

| (2) Width of effective plating

included in the cross-sectional area

|

The lesser of the following

w = 80t mm

or

w = 700s mm

|

| Symbols

|

|

|

|

|

|

|

|

r

|

= |

least radius of gyration of stiffener with effective

plating, in mm, and is to be taken as:

|

|

|

s

|

= |

spacing of stiffeners, in metres, but not to exceed

1,10 m |

|

|

t

|

= |

thickness of plating, in mm |

|

|

w

|

= |

width of effective plating, in mm |

|

|

A

|

= |

cross-sectional area of stiffening member inclusive of

effective plating, in cm2

|

|

|

Ip

|

= |

least moment of inertia of stiffener with effective

plating, in cm4

|

|

|

P

|

= |

load supported by stiffener, in tonne-f |

|

|

|

Note The depth of stiffeners supporting concentrated loads is

to be not less than 75 mm.

|

2.3 Bulkheads in cargo spaces

2.3.1 Bulkheads

in cargo holds which are regularly exposed to contact with grabs or

falling cargo are to be efficiently protected or the scantlings increased

in order to reduce damage.

|