1 General

The purpose of these guidelines is to assist verifiers of the Energy

Efficiency Design Index (EEDI) of ships in conducting the survey and certification

of the EEDI, in accordance with regulations 5, 6, 7, 8 and 9 of MARPOL Annex VI, and

assist shipowners, shipbuilders, manufacturers and other interested parties in

understanding the procedures for the survey and certification of the EEDI.

2.1 Verifier means an Administration, or organization duly

authorized by it, which conducts the survey and certification of the EEDI in

accordance with regulations 5, 6, 7, 8 and 9 of MARPOL Annex VI and these

Guidelines.

2.2 Ship of the same type means a ship the hull form (expressed in

the lines such as sheer plan and body plan), excluding additional hull features such

as fins, and principal particulars of which are identical to that of the base ship.

2.3 Tank test means model towing tests, model self-propulsion

tests and model propeller open water tests. Numerical calculations may be accepted

as equivalent to model propeller open water tests or used to complement the tank

tests conducted (e.g. to evaluate the effect of additional hull features such as

fins, etc. on ships' performance) with the approval of the verifier.

3 Application

These guidelines should be applied to new ships for which an application for an

initial survey or an additional survey specified in regulation 5 of MARPOL Annex VI

has been submitted to a verifier.

4 Procedures for survey and certification

4.1.1 The attained EEDI should be calculated in accordance with regulation 20 of MARPOL Annex VI and the

2018 Guidelines on the method of calculation of the attained Energy

Efficiency Design Index (EEDI) for new ships (resolution MEPC.308(73)) (EEDI Calculation Guidelines).

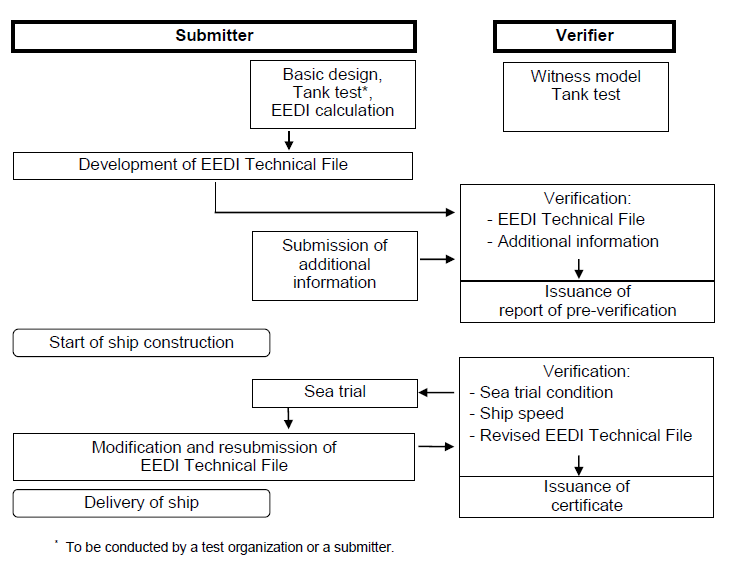

Survey and certification of the EEDI should be conducted in two stages: preliminary

verification at the design stage and final verification at the sea trial. The basic

flow of the survey and certification process is presented in figure 1.

4.1.2 The information used in the verification process may contain

confidential information of submitters which requires Intellectual Property Rights

(IPR) protection. In the case where the submitter wants a non-disclosure agreement

with the verifier, the additional information should be provided to the verifier

upon mutually agreed terms and conditions.

Figure 1: Basic flow of survey and certification process

4.2 Preliminary verification of the attained EEDI at the design stage

4.2.1 For the preliminary verification at the design stage, an

application for an initial survey and an EEDI Technical File containing the

necessary information for the verification and other relevant background documents

should be submitted to a verifier.

4.2.2 The EEDI Technical File should be written at least in English. The

EEDI Technical File should include as a minimum, but not limited to:

-

.1 deadweight (DWT) or gross tonnage (GT) for passenger and

ro-ro passenger ships, the maximum continuous rating (MCR) of the main

and auxiliary engines, the ship speed (Vref), as

specified in paragraph 2.2.2 of the EEDI Calculation Guidelines, type of

fuel, the specific fuel consumption (SFC) of the main engine at

75% of MCR power, the SFC of the auxiliary engines at 50% MCR

power, and the electric power tablefootnote for certain ship types, as

necessary, as defined in the EEDI Calculation Guidelines;

-

.2 power curve(s) (kW – knot) estimated at design stage under

the condition as specified in paragraph 2.2.2 of the EEDI Calculation

Guidelines, and, in the event that the sea trial is carried out in a

condition other than the above condition, also a power curve estimated

under the sea trial condition;

-

.3 principal particulars, ship type and the relevant information to

classify the ship as such a ship type, classification notations and an

overview of the propulsion system and electricity supply system on

board;

-

.4 estimation process and methodology of the power curves at design

stage;

-

.5 description of energy saving equipment;

-

.6 calculated value of the attained EEDI, including the calculation

summary, which should contain, at a minimum, each value of the

calculation parameters and the calculation process used to determine the

attained EEDI;

-

.7 calculated values of the attained EEDIweather and

fw value (not equal to 1.0), if those

values are calculated, based on the EEDI Calculation Guidelines; and

-

.8 for LNG carriers:

-

.1 type and outline of propulsion systems (such as direct drive

diesel, diesel electric, steam turbine);

-

.2 LNG cargo tank capacity in m3 and BOR

as defined in paragraph 2.2.5.6.3 of the EEDI Calculation

Guidelines;

-

.3 shaft power of the propeller shaft after transmission gear at

100% of the rated output of motor (MPPMotor)

and η(i) for diesel electric;

-

.4 maximum continuous rated power

(MCRSteamTurbine) for steam turbine;

and

-

.5 SFCSteamTurbine for steam

turbine, as specified in paragraph 2.2.7.2 of the EEDI

Calculation Guidelines.

A sample of an EEDI Technical File is provided in appendix 1.

4.2.3 For ships equipped with dual-fuel engine(s) using LNG and fuel oil,

the C F-factor for gas (LNG) and the specific fuel consumption

( SFC) of gas fuel should be used by applying the following criteria as a

basis for the guidance of the Administration:

-

.1 final decision on the primary fuel rests with the

Administration;

-

.2 the ratio of calorific value of gas fuel (LNG) to total

marine fuels (HFO/MGO), including gas fuel (LNG) at design conditions

should be equal to or larger than 50% in accordance with the formula

below. However, the Administration can accept a lower value of the

percentage taking into account the intended voyages:

-

whereby:

-

Vgas is the total net tank volume of gas

fuel on board in m3;

-

Vliquid is the total net tank volume of

every liquid fuel on board in m3;

-

ρgas is the density of gas fuel in

kg/m3;

-

ρliquid is the density of every

liquid fuel in kg/m3;

-

LCVgas is the low calorific value

of gas fuel in kJ/kg;

-

LCVliquid is the low calorific

value of liquid fuel in kJ/kg;

-

Kgas is the filling rate for gas

fuel tanks;

-

Kliquid is the filling rate for

liquid fuel tanks.

-

Normal density, Low Calorific Value and filling rate

for tanks of different kinds of fuel are listed below.

-

| Type of

fuel

|

Density

(kg/m3)

|

Low

Calorific Value

(kJ/kg)

|

Filling

rate for tanks

|

| Diesel/Gas

Oil

|

900

|

42700

|

0.98

|

| Heavy Fuel

Oil

|

991

|

40200

|

0.98

|

Liquefied

Natural Gas

(LNG)

|

450

|

48000

|

0.95*

|

* Subject to verification of tank filling limit.

-

.3 in case the ship is not fully equipped with dual-fuel

engines, the CF-factor for gas (LNG) should apply only for those

installed engines that are of dual-fuel type and sufficient gas fuel

supply should be available for such engines; and

-

.4 LNG fuelling solutions with exchangeable (specialized) LNG

tank-containers should also fall under the terms of LNG as primary

fuel.

4.2.4 The SFC of the main and auxiliary engines should be quoted

from the approved NO x Technical File and should be corrected to the value

corresponding to the ISO standard reference conditions using the standard lower

calorific value of the fuel oil (42,700 kJ/kg), referring to ISO 15550:2002 and ISO

3046-1:2002. For the confirmation of the SFC, a copy of the approved

NO x Technical File and documented summary of the correction

calculations should be submitted to the verifier. In cases where the NO x

Technical File has not been approved at the time of the application for initial

survey, the test reports provided by manufacturers should be used. In this case, at

the time of the sea trial verification, a copy of the approved NO x

Technical File and documented summary of the correction calculations should be

submitted to the verifier. In the case that gas fuel is determined as primary fuel

in accordance with paragraph 4.2.3 and that installed engine(s) have no approved

NO x Technical File tested in gas mode, the SFC of gas mode

should be submitted by the manufacturer and confirmed by the verifier.

-

Note:

SFC in the NOx Technical File are the values of a

parent engine, and the use of such value of SFC for the EEDI

calculation for member engines may have the following technical issues

for further consideration:

-

.1 the definition of "member engines" given in the

NOx Technical File is broad and specification of engines

belonging to the same group/family may vary; and

-

.2 the rate of NOx emission of the parent engine

is the highest in the group/family – i.e. CO2 emission, which

is in the trade-off relationship with NOx emission, can be

lower than the other engines in the group/family.

4.2.5 For ships to which regulation 21 of MARPOL Annex VI applies, the

power curves used for the preliminary verification at the design stage should be

based on reliable results of tank tests. A tank test for an individual ship may be

omitted based on technical justifications such as availability of the results of

tank tests for ships of the same type. In addition, the omission of tank tests is

acceptable for a ship for which sea trials will be carried out under the condition

as specified in paragraph 2.2.2 of the EEDI Calculation Guidelines, upon agreement

of the shipowner and shipbuilder and with the approval of the verifier. To ensure

the quality of tank tests, the ITTC quality system should be taken into account.

Model tank tests should be witnessed by the verifier.

4.2.6 The verifier may request further information from the submitter,

in addition to that contained in the EEDI Technical File, as necessary, to examine

the calculation process of the attained EEDI. For the estimation of the ship speed

at the design stage much depends on each shipbuilder's experience, and it may not be

practicable for any person/organization other than the shipbuilder to fully examine

the technical aspects of experience-based parameters, such as the roughness

coefficient and wake scaling coefficient. Therefore, the preliminary verification

should focus on the calculation process of the attained EEDI to ensure that it is

technically sound and reasonable and follows regulation 20 of MARPOL Annex VI and the EEDI

Calculation Guidelines.

-

Note 1: A possible way forward for more robust

verification is to establish a standard methodology of deriving the ship

speed from the outcome of tank tests, by setting standard values for

experience-based correction factors such as roughness coefficient and

wake scaling coefficient. In this way, ship-by-ship performance

comparisons could be made more objectively by excluding the possibility

of arbitrary setting of experience-based parameters. If such

standardization is sought, this would have an implication on how the

ship speed adjustment based on sea trial results should be conducted, in

accordance with paragraph 4.3.8 of these Guidelines.

-

Note 2: A joint industry standard to support the method and role

of the verifier is expected to be developed.

4.2.7 Additional information that the verifier may request the submitter

to provide includes, but is not limited to:

-

.1 descriptions of a tank test facility; this should include the name of

the facility, the particulars of tanks and towing equipment, and the

records of calibration of each monitoring equipment;

-

.2 lines of a model ship and an actual ship for the verification of the

appropriateness of the tank test; the lines (sheer plan, body plan and

half-breadth plan) should be detailed enough to demonstrate the

similarity between the model ship and the actual ship;

-

.3 lightweight of the ship and displacement table for the verification of

the deadweight;

-

.4 detailed report on the method and results of the tank

test; this should include at least the tank test results at sea trial

condition and under the condition as specified in paragraph 2.2.2 of the

EEDI Calculation Guidelines;

-

.5 detailed calculation process of the ship speed, which should include

the basis for the estimation of experience-based parameters such as

roughness coefficient and wake scaling coefficient;

-

.6 reasons for exempting a tank test, if applicable; this should include

lines and tank test results of ships of the same type, and the

comparison of the principal particulars of such ships and the ship in

question. Appropriate technical justification should be provided,

explaining why the tank test is unnecessary; and

-

.7 for LNG carriers, detailed calculation process of

PAE and SFCSteamTurbine.

4.2.8 The verifier should issue the report on the Preliminary

Verification of the EEDI after it has verified the attained EEDI at the design

stage, in accordance with paragraphs 4.1 and 4.2 of these Guidelines.

4.3 Final verification of the attained EEDI at sea trial

4.3.1 Sea trial conditions should be set as the conditions specified in

paragraph 2.2.2 of the EEDI Calculation Guidelines, if possible.

4.3.2 Prior to the sea trial, the following documents should be

submitted to the verifier: a description of the test procedure to be used for the

speed trial, the final displacement table and the measured lightweight, or a copy of

the survey report of deadweight, as well as a copy of the NOx Technical

File, as necessary. The test procedure should include, as a minimum, descriptions of

all necessary items to be measured and corresponding measurement methods to be used

for developing power curves under the sea trial condition.

4.3.3 The verifier should attend the sea trial and confirm:

4.3.4 Draught and trim should be confirmed by the draught measurements

taken prior to the sea trial. The draught and trim should be as close as practical

to those at the assumed conditions used for estimating the power curves.

4.3.5 Sea conditions should be measured in accordance with ITTC

Recommended Procedure 7.5-04-01-01.1 Speed and Power Trials 2017 or ISO 15016:2015.

4.3.6 Ship speed should be measured in accordance with ITTC Recommended

Procedure 7.5-04-01-01.1 Speed and Power Trials 2017 or ISO 15016:2015, and at more

than two points of which range includes the power of the main engine as specified in

paragraph 2.2.5 of the EEDI Calculation Guidelines.

4.3.7 The main engine output, shaft power of propeller shaft (for LNG

carriers having diesel electric propulsion system) or steam turbine output (for LNG

carrier having steam turbine propulsion system) should be measured by shaft power

meter or a method which the engine manufacturer recommends and the verifier

approves. Other methods may be acceptable upon agreement of the shipowner and

shipbuilder and with the approval of the verifier.

4.3.8 The submitter should develop power curves based on the measured

ship speed and the measured output of the main engine at sea trial. For the

development of the power curves, the submitter should calibrate the measured ship

speed, if necessary, by taking into account the effects of wind, current, waves,

shallow water, displacement, water temperature and water density in accordance with

ITTC Recommended Procedure 7.5-04-01-01.2 Speed and Power Trials 2017 or ISO

15016:2015. Upon agreement with the shipowner, the submitter should submit a report

on the speed trials including details of the power curve development to the verifier

for verification.

4.3.9 The submitter should compare the power curves obtained as a result

of the sea trial and the estimated power curves at the design stage. In case

differences are observed, the attained EEDI should be recalculated, as necessary, in

accordance with the following:

-

.1 for ships for which sea trial is conducted under the

condition as specified in paragraph 2.2.2 of the EEDI Calculation

Guidelines: the attained EEDI should be recalculated using the measured

ship speed at sea trial at the power of the main engine as specified in

paragraph 2.2.5 of the EEDI Calculation Guidelines; and

-

.2 for ships for which sea trial cannot be conducted under

the condition as specified in paragraph 2.2.2 of the EEDI Calculation

Guidelines: if the measured ship speed at the power of the main engine

as specified in paragraph 2.2.5 of the EEDI Calculation Guidelines at

the sea trial conditions is different from the expected ship speed on

the power curve at the corresponding condition, the shipbuilder should

recalculate the attained EEDI by adjusting ship speed under the

condition as specified in paragraph 2.2.2 of the EEDI Calculation

Guidelines by an appropriate correction method that is agreed by the

verifier.

-

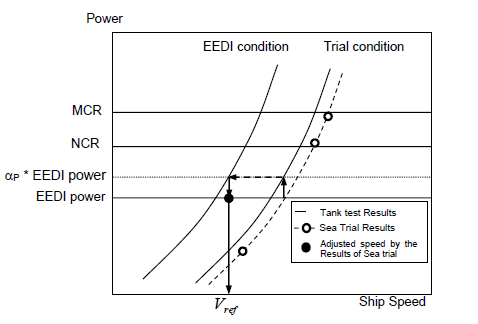

.3 An example of the scheme of conversion from trial condition to EEDI

condition at EEDI power is given as follows:

Vref is obtained from the results of the

sea trials at trial condition using the speed-power curves predicted by

the tank tests. The tank tests shall be carried out at both draughts:

trial condition corresponding to that of the S/P trials and EEDI

condition. For trial conditions the power ratio αP between

model test prediction and sea trial result is calculated for constant

ship speed. Ship speed from model test prediction for EEDI condition at

EEDI power multiplied with αP is

Vref.

where:

PTrial,P : power at trial condition

predicted by the tank tests

PTrial,S : power at trial condition

obtained by the S/P trials

αP: power ratio

-

.4 Figure 2 shows an example of the scheme of conversion to derive the

resulting ship speed at EEDI condition ( Vref) at EEDI

power.

Figure 2: An example of scheme of conversion from

trial condition to EEDI condition at EEDI power

-

Note: Further consideration would be necessary for

speed adjustment methodology in paragraphs 4.3.9.2 to 4.3.9.4 of these

Guidelines. One of the concerns relates to a possible situation where

the power curve for sea trial condition is estimated in an excessively

conservative manner (i.e. power curve is shifted in a leftward

direction) with the intention to get an upward adjustment of the ship

speed by making the measured ship speed at sea trial easily exceed the

lower-estimated speed for sea trial condition at design stage.

4.3.10 In cases where the finally determined deadweight/gross tonnage

differs from the designed deadweight/gross tonnage used in the EEDI calculation

during the preliminary verification, the submitter should recalculate the attained

EEDI using the finally determined deadweight/gross tonnage. The finally determined

gross tonnage should be confirmed in the Tonnage Certificate of the ship.

4.3.11 The electrical efficiency η(i) should be taken

as 91.3% for the purpose of calculating the attained EEDI. Alternatively, if a value

of more than 91.3% is to be applied, η(i) should be obtained by

measurement and verified by a method approved by the verifier.

4.3.12 In case where the attained EEDI is calculated at the preliminary

verification by using SFC based on the manufacturer's test report, due to the

non-availability at that time of the approved NOx Technical File, the

EEDI should be recalculated by using SFC in the approved NOx

Technical File. Also, for steam turbines, the EEDI should be recalculated by using

SFC confirmed by the Administration, or an organization recognized by the

Administration, at the sea trial.

4.3.13 The EEDI Technical File should be revised, as necessary, by

taking into account the results of sea trials. Such revision should include, as

applicable, the adjusted power curve based on the results of sea trials (namely,

modified ship speed under the condition as specified in paragraph 2.2.2 of the EEDI

Calculation Guidelines), the finally determined deadweight/gross tonnage, η

for LNG carriers having diesel electric propulsion system and SFC described

in the approved NOx Technical File, and the recalculated attained EEDI

based on these modifications.

4.3.14 The EEDI Technical File, if revised, should be submitted to the

verifier for confirmation that the (revised) attained EEDI is calculated in

accordance with regulation 20 of MARPOL Annex VI and the EEDI

Calculation Guidelines.

4.4 Verification of the attained EEDI in case of major conversion

4.4.1 In cases of a major conversion of a ship, the shipowner should

submit to a verifier an application for an additional survey with the EEDI Technical

File duly revised, based on the conversion made and other relevant background

documents.

4.4.2 The background documents should include as a minimum, but are not

limited to:

-

.1 details of the conversion;

-

.2 EEDI parameters changed after the conversion and the technical

justifications for each respective parameter;

-

.3 reasons for other changes made in the EEDI Technical File, if any; and

-

.4 calculated value of the attained EEDI with the calculation summary,

which should contain, as a minimum, each value of the calculation

parameters and the calculation process used to determine the attained

EEDI after the conversion.

4.4.3 The verifier should review the revised EEDI Technical File and

other documents submitted and verify the calculation process of the attained EEDI to

ensure that it is technically sound and reasonable and follows regulation 20 of MARPOL Annex VI and the EEDI

Calculation Guidelines.

4.4.4 For verification of the attained EEDI after a conversion, speed

trials of the ship are required, as necessary.

|