Section

4 Pile design

4.1 Driven pile design

4.1.1 Generally speaking, the methodology for driven pile presented in ISO

19901-4 Petroleum and natural gas industries – Specific requirements for offshore

structures – Part 4: Geotechnical and foundation design considerations

presents a suitable basis for driven pile design.

4.1.2 Further guidance on driven pile design is given in the following Sections.

4.2 Pile axial capacity

4.2.1 It should be noted that the reliability of the ‘main text method’ for

axial capacity in sands in Section 8.1, ISO 19901-4 Petroleum and natural gas

industries – Specific requirements for offshore structures – Part 4:

Geotechnical and foundation design considerations is below that of the

CPT-based methods. Whilst the ‘main text method’ may be suitable for a preliminary

assessment of pile capacity, the CPT-based design methods, such as those presented

for sand in the Annex A of ISO 19901-4 Petroleum and natural gas industries –

Specific requirements for offshore structures – Part 4: Geotechnical and

foundation design considerations, generally present a more reliable method

for assessment of axial capacity. Lehane et al. (2017) make a comparison of

the different methods by examining the measured values of capacity to calculated

values and determination of the coefficient of variation of the different methods.

However, it should be noted that there are occasions when the CPT-based methods for

sand give a wide range of capacity estimates; therefore, it may be prudent to

calculate capacity using more than one method before committing to a design.

4.2.2 Aside from the main text method for clay in Section 8.1, ISO 19901-4

Petroleum and natural gas industries – Specific requirements for offshore

structures – Part 4: Geotechnical and foundation design considerations,

other methods for clays that may be applied include the Imperial College Pile Design

method, NGI-05 and Fugro-96 method, as referred to by Lehane et al.

(2017).

4.2.3 When selecting a method for design it is important to ensure that it is applicable

and calibrated to the soil types under question. For example, if the soil type is

unconventional, such as silt or carbonate, then it may be the case that a pile

capacity method cannot be directly applied, or that more than one method should be

considered for the same soil type to ensure that the range of possible soil and pile

behaviours is examined.

4.2.4 It is important that sufficient site investigation data is collected to allow a

confident application of a particular pile design method, both in terms of quantity

and quality.

4.2.5 For assessment of pile axial capacity, the use of a reliable pile design method is a

preferred approach, rather than an alternative that may place reliance upon proof of

pile capacity during installation. Use of dynamic testing during installation

requires significant experience in similar soil types and requires conversion to an

equivalent static capacity and application of various corrections (e.g. due to scour

or cyclic loading). This leads to uncertainty in pile length required and may create

longer piles with other impacts such as increased installation time and additional

noise, see for example Jardine et al. (2015).

4.2.6 Ageing of skin friction in sands and clays is a well-recognised concept. It may be

used but would require careful demonstration that it is valid for the soil

conditions and piles in question, taking into account various factors such as cyclic

loading, timing of maximum loads after installation and any pile brittleness effects

on the structure. It is important to differentiate between setup effects that occur

relatively quickly after driving is complete (i.e. days, weeks or months), versus

ageing effects that occur over a much longer time (i.e. months or years).

4.3 Pile lateral response

4.3.1 There are various PY curve models available for the analyses of lateral stiffness and

capacity in clays. The PY curve models tend to have an empirical, or semi empirical,

basis and were developed taking into account a range of different conditions –

either intentional, or coincidental. When selecting a PY curve model the following

conditions should be considered.

4.3.2 Cyclic or static loading: The load condition being analysed and whether it tends

towards cyclic or static when considering the soil types and their likely behaviour.

For example, for a 50 or 100 year in-place condition it is common to assume that

cyclic degradation has occurred and therefore a cyclic PY curve should be used.

However, under other conditions, such as fatigue loading, the majority of fatigue

damage may occur when the soil is not experiencing significant effects of cyclic

degradation (either due to lack of degradation or recovery from previous

degradation) and in this case it may be more appropriate to use static PY curves. A

final example is for pushover loading where the displacements involved are higher

than the zone typically affected by cyclic degradation and therefore at

displacements associated with ultimate pushover state, static resistance without

cyclic degradation is more appropriate (Gilbert et al., 2010).

4.3.3 Implementing the model as developed: Many PY curve models do not consider the effect

of axial loading on lateral response, or vice versa. In this case it is appropriate

to consider if the two loading types may interact and whether adjustment to the

model should be made to account for this. For example, the Jeanjean (2017)

model in clays would require axial loading to be accounted for.

4.3.4 It should be ensured that it is appropriate to apply the PY curve model to the soil

type(s) under question. For example, the pile tests used by Reese and Van Impe

(2005) to develop the PY curve model in stiff clay were performed in high

plasticity clay that shows a very large reduction in post peak resistance when

compared to more typical North Sea clays.

4.3.5 The concept of conservatism does not necessarily apply to the assessment

of lateral pile stiffness and capacity. For instance, it is not necessarily

conservative for a structure if the foundation model used is 'soft' or 'weak'.

Hence, the assessment of lateral pile capacity and stiffness should be as accurate

as possible, giving due attention to uncertainties where they exist.

4.4 PY curve models

4.4.1 Jeanjean (2017) presents a comprehensive discussion of the main

text PY curve model for clays as presented in ISO 19901-4 Petroleum and natural

gas industries – Specific requirements for offshore structures – Part 4:

Geotechnical and foundation design considerations and propose an updated

version that may be more appropriate. Through an examination of the theoretical

background the development of the method is explained and they further refine the

method and definition of input parameters and assumptions generally leading to a

significant increase in lateral resistance and stiffness for monotonic loading.

4.4.2 Zhang et al. (2017) further expand on the method for monotonic PY curves,

presented by Jeanjean (2017), to give a methodology for cyclic PY curves. The

method can account for non-symmetrical loading and a simplified approach can be

derived to allow easier integration of the PY curves into PSI modelling for

structural analyses. In order to use the simplified method, it would need

appropriate calibration for local soil conditions and the nature of cyclic loading

applicable to the structure in question.

4.4.3 The method proposed by Jeanjean (2017) and Zhang et al. (2017) requires

the input of site-specific direct simple shear strength test results for monotonic

and cyclic loading in order to derive the PY curve shape (i.e.

P/Pu with y/D). However, in cases where such data are

not available, for example in preliminary design, recommendations are given for

different shear strength ranges.

4.4.4 Jeanjean (2017) concludes that diameter effects are appropriately

captured within the method and as such the proposed method can be applied without

correction. The alpha value can be calculated using the main text method for axial

capacity in clays presented in ISO 19901-4 Petroleum and natural gas industries –

Specific requirements for offshore structures – Part 4: Geotechnical and

foundation design considerations. However, the final alpha value selected

for calculation of PY curves may also need adjustment to account for the combined

effect of axial and lateral loading.

4.5 Refined assessment of lateral pile response

4.5.1 It is generally recognised that the PY curve methods included in common

International Standards such as ISO 19901-4 Petroleum and natural gas Industries

– Specific requirements for offshore structures – Part 4: Geotechnical and

foundation design considerations are not appropriate for large diameter

piles except, perhaps, as a first approach to preliminary design. Byrne et al.

(2015) and Byrne (2017) present the results of the pile soil analyses

(PISA) project which aimed to provide a suitable process to design large diameter

piles as well as to provide a more accurate assessment for smaller diameter piles if

required. This process considered a rule-based method which takes basic strength and

stiffness parameters to derive soil reaction curves and a numerical based method

which takes more detailed strength and stiffness parameters combined with the use of

a suite of detailed three-dimensional finite element analyses to calibrate a simple

one-dimensional (1D) finite element model (i.e. PY curves). The rule-based method is

considered suitable for initial feasibility or concept designs, whereas the

numerical based method is generally considered necessary further into the detailed

design process.

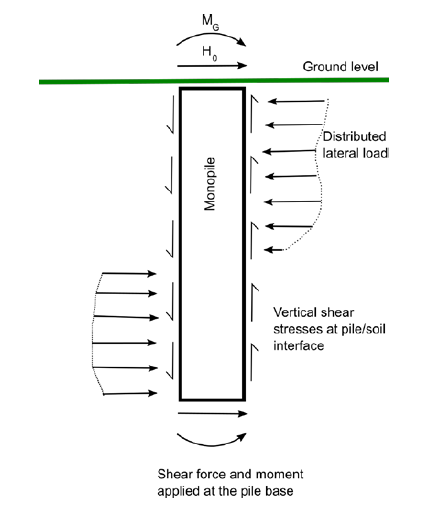

4.5.2 As shown in Figure 3.4.1 Components of soil capacity considered under PISA methodology (reproduced

from Byrne, 2017), the PISA

methodology also considers additional sources of soil resistance to resist lateral

and moment loading including vertical stresses due to external wall friction, shear

force at the pile base and a base moment. These additional components of capacity

are usually combined with traditional PY curves used in a 1D finite element analyses

and in PSI models through the structural design process. However, caution should be

exercised with a more refined assessment to ensure that components of axial

resistance (e.g. friction) are not double counted as lateral resistance (or vice

versa) without an assessment of interaction to ensure the design does not become

unconservative.

4.5.3 Care should be taken with selection of soil properties given their

differing influence on ULS, SLS and FLS design cases and especially the influence of

cyclic loading on pile response and capacity. Byrne (2017) also recognises

that engineering judgement is required in using the process to ensure that factors

such as installation effects or cyclic loading are appropriately considered in use

of the methodology that has currently only been developed for static loading.

See

Ch 3, 4.4 PY curve models for further

discussion on PY curve methods.

4.6 Monopile design

4.6.1 A monopile design shall take into account the following aspects:

- all ULS, SLS and FLS requirements taking into account the load and

resistance factors where appropriate;

- it should be ensured that rotations and displacements (accumulated or

otherwise) do not exceed a specified limit over the required lifetime of the

monopile including pre-service, in-service and post service conditions. Any

rotations or displacements under applied loading may require to be added to

construction or installation tolerances during design; and

- generally speaking, an ULS design approach for lateral pile design is

unsuitable as excessive displacements would be required for full

mobilisation of lateral resistance. Therefore, a serviceability approach can

be taken for design. Determining appropriate monopile penetration depth may

be assisted by considering the decrease in pile head rotation with

increasing penetration. The required pile length may be indicated where any

benefits in terms of the performance of the pile (e.g. stiffness, rotation

or, perhaps, displacement) become very limited. According to Achmus et

al. (2017) this generally leads to a reliable design when combined

with an appropriate PY curve approach.

4.6.2 When designing monopiles it is important to take accumulated

displacements and rotations into account as they may impact the ability of the

foundation to function properly over the entire service life. Accumulated

displacements have been the subject of various research including Leblanc et al.

(2010) and Rudolph et al. (2014). In the current approaches, such as

those presented in ISO 19901-4 Petroleum and natural gas industries – Specific

requirements for offshore structures – Part 4: Geotechnical and foundation

design considerations, the direction of cyclic loading is assumed to be

constant, however, as presented by Rudolph et al. (2014), this is unlikely to

be the case with various short-term, seasonal and long-term variation in load

direction and magnitude. There are various relationships for predicting accumulated

rotation, including that in DGGT (2013) where a logarithmic approach is

suggested.

4.6.3 For monopiles it generally appears to be the case that variation in

loading direction causes displacements that may be significantly higher than that

caused by uni-directional loading. Therefore, it is important to assess the

potential accumulated displacement and rotation taking into account the soil type

and loading characteristics combined with appropriate methodology such as that

presented by Rudolph et al. (2014) and Leblanc et al. (2010). Where

accumulated rotations or displacements could be critical, it may be appropriate to

ensure that an appropriate safety margin is included either in the specified

allowable rotation or displacement or by application of load and material factors to

the design methods.

Figure 3.4.1 Components of soil capacity considered under PISA methodology (reproduced

from Byrne, 2017)

4.7 Driven pile axial capacity in chalk

4.7.1 Chalk is found extensively across north-west Europe and is a fine-grained material

consisting of calcite debris with a typical unconfined compressive strength (UCS) of

3–5 MPa and cone resistance in the order of 4–50 MPa (Carrington et al.,

2011).

4.7.2 According to Lord et al. (2002) axial shaft friction for driven open-ended

steel tubular piles should be limited to 20 kPa in low and medium density chalk and

shaft resistances in the order of 120 kPa may be expected in high-density grade A

chalk. Shaft resistance in chalk is dependent upon a number of mechanisms including

installation method, remoulding, excess pore pressures, ‘tightening’ of

discontinuities, strength of the chalk itself and the degree of porosity. Large

set-up may be expected after driving. For example, Buckley et al. (2017)

found that the remoulded zone varied in a range 0,59–1,64 times the pile wall

thickness.

4.7.3 The range of frictions presented by Lord et al. (2002) did not allow an

optimised design for low to medium density chalk and in recent years different

investigators have sought to improve the methodology.

4.7.4 Carrington et al. (2011) presented an assessment method for shaft resistance

based upon laboratory testing including cyclic direct simple shear tests and

presented an improvement for shaft friction such that a range of 20–50 kPa could be

used for low to medium density chalk. Ciavaglia et al. (2017) conducted a

series of onshore pile tests in low to medium density chalk and the results showed

that shaft friction a few days after driving was an average of 23 kPa and that, for

an aged pile, this increased sevenfold to 168 kPa. Buckley et al. (2017)

found similar results for driven piles where resistance at the end of driving was in

the range 15–17 kPa and a setup factor of up to 5,3 was found 246 days after

driving. Buckley et al. (2017) also tested the instrumented Imperial College

piles that were installed by pushing and they found that these piles had a setup

factor of less than 1,0: this has significant implications for some piles, such as

large diameter piles or those with significant structural weight applied during

installation, that are often installed to a greater or complete extent by

self-penetration and may not experience the same friction enhancing effects that

driven piles do.

4.7.5 When extrapolating the use of field tests into design, care should be taken to

include the effect of lateral loading on shaft friction. For example, Ciavaglia

et al. (2017) found that if a pile was subjected to lateral loads up to 50

per cent of the lateral capacity, the effect of setup was reduced such that shaft

resistance was up to 65 per cent lower. Efforts should therefore be made to assess

the degree to which lateral capacity will be mobilised and what influence this may

have on shaft friction and this will depend upon pile flexibility. In addition,

where using field tests to support offshore pile design it should be ensured that

the chalk characteristics and nature of the applied loading are similar; for

example, to take account of any cyclic effects. These effects will have different

impacts on monopiles or driven piles.

4.7.6 According to Lord et al. (2002) driving in grade A high density chalk can be

difficult, whereas driving in lower grade B, C and D chalk will be easier. Set-up

effects can be very significant and although this is beneficial for shaft resistance

it can have a significant impact if any driving delays are encountered, with a

higher risk of premature refusal.

4.8 Driven pile capacity in rock

4.8.1 High shaft frictions can be generated for driven piles in rock, for example, as

reported by Rodway and Rowe (1980) and Long (1991). The driven pile is

sometimes used with relief drilling to ensure that further pile penetration can be

achieved. As yet, there is little practical experience on shaft capacity in rock and

the impact of relief drilling on shaft capacity.

4.8.2 If driven piles in rock, with or without relief drilling, are critical to the pile

design (i.e. a significant proportion of the pile capacity is due to a driven

element in rock), then it may be prudent to perform appropriate pile testing to

optimise pile lengths. A non-optimal pile design may result in longer piles that

become too difficult to install with higher potential for premature refusal.

4.9 Drilled and grouted pile capacity

4.9.2 CIRIA (2004) gives a useful overview of issues of pile design in weak rock and

expansion of some key issues is provided in the following Sections.

4.9.3 Where it is expected that drilled and grouted piles may be used, then a literature

review should be performed to investigate methods that may be suitable for the

actual conditions and rock types likely to be encountered. The site investigation

and laboratory testing should then be designed such that sufficient information can

be gained for an efficient design. Key influencing factors of drilled & grouted

pile design include:

- cleanliness and roughness of the drilled hole which may be assessed during

site investigation and construction by the use of hole profiling techniques,

such as an acoustic televiewer;

- UCS of the rock using UCS tests. UCS test data may be supplemented by point

load test data provided the interpretation of results, for conversion to an

equivalent UCS strength, is properly calibrated;

- the site investigation should aim to identify the presence of

discontinuities or faults in the rock. Faults or discontinuities may cause

difficulty during installation either by hole collapse or by leakage of

grout;

- petrographic slices to investigate rock structure may help to understand the

likely response of the rock under loading. For example, it may be apparent

from a petrographic slice that the rock has an open structure that may be

vulnerable to collapse during installation or under applied stress;

- techniques such as P-S logging may provide an indication of overall response

of the rock mass; and

- CIRIA (2004) gives further discussion on parameters such as hole

roughness classification, adhesion factor and alpha value. Furthermore,

Williams and Pells (1981) describe the inclusion of a β factor to

account for the influence of rock quality on shaft friction.

4.9.4 In weak rock, an approach such as that by Kulhawy and Phoon (1993) may be

suitable for defining shaft resistance. It may be appropriate to apply a limit to

the frictions determined. Deliberate roughening may be used to enhance the shaft

friction; for example, by the inclusion of grooves in the drilled hole.

4.9.5 Once the shaft friction has been determined, it is necessary to confirm

that grout-steel friction will not limit the amount of shaft friction that can be

mobilised. The methodology presented in ISO 19902 Petroleum and natural gas

industries – Fixed steel offshore structures for calculating the capacity of

a grouted connection may be used; making appropriate assumptions for the smoothness

of the pile steel surface.

4.9.6 If excessive debris has collected near to the hole base and remains present then end

bearing may only be mobilised at excessive displacements; unless the debris is

removed. Furthermore, unless the pile is plugged (e.g. by grout) the end bearing

will be restricted to that on the pile annulus although this may be substantial. It

should also be noted that the displacements required to mobilise end bearing may be

such that significant degradation is caused on shaft friction and in this case it is

common practice to only count shaft friction or end bearing in design.

4.9.7 It may also be appropriate to consider the use of pile testing in similar rock types

(perhaps onshore) to optimise the pile design or laboratory tests, such as constant

normal stiffness interface friction testing, to help definition of pile

behaviour.

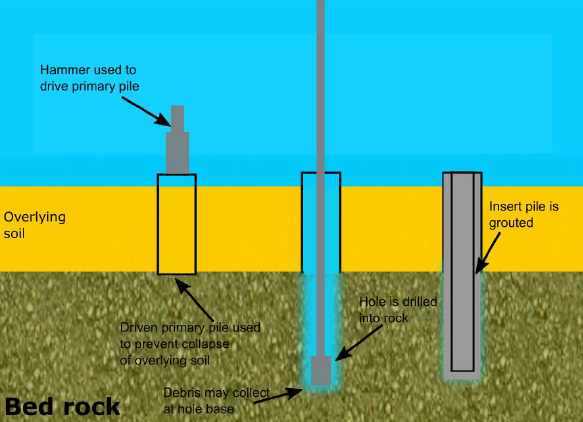

Figure 3.4.2 Typical drilled and grouted pile configuration

4.9.8 There are a number of potential issues to be considered during installation of

drilled and grouted piles. These include:

- during drilling, it should be ensured that the hole will remain

open sufficiently long in order that the pile can be installed and the

grouting operation completed. If the hole does not remain stable, then it is

possible that the pile capacity will be degraded and collapse of soil or

rock around the hole may occur. This collapse of soil could undermine any

mudmats that are being used to provide temporary stability. Hole stability

issues can be overcome by using a driven primary pile until stable rock or

soil conditions are reached; then an insert pile will be used to form the

grouted section;

- if using blind-ended (or closed-ended) tubular piles it should be checked

that the pile will not float once grout has been placed and prior to

setting; and

- where drilling fluids other than seawater are used their impact on the pile

performance should be assessed.

4.10 Suction caisson design

4.10.1 Where suction caissons (also called suction piles or suction buckets) are

considered, it should be first established that the concept is applicable.

4.10.2 In addition to general aspects discussed under the design basis, the design process

will need to make assumptions around the following aspects that will then be further

refined through the design process:

- cyclic effects;

- conditions or assumptions conditions such as contact of the caisson lid with

soil, or under lid grouting where appropriate;

- whether suction assistance is required during installation; or if the

caissons will penetrate under self-weight of the structure and foundation;

- the combination of suction caisson penetration and the necessity of an

allowance for heave of the internal soil plug during installation; and

- installation and extraction may be more sensitive to soil type and soil

layering than may generally be expected for alternative foundation types

such as driven piles.

4.10.3 It is common to practise perform sizing of a suction caisson using

simplified methodology such as the work by Suryasentana et al. (2017) or

alternative formulations of upper bound methods, see for example Hamilton and

Murff (1995). Following this the suitability of design should then be

confirmed suitable by the use of finite element analyses that can more precisely

take into account aspects such as soil layering or other soil properties.

4.10.4 Where a structural analysis requires stiffness input it should be ensured that the

stiffness matrix in the structural analyses is compatible with the level of loads

used. Many structural analyses packages only accept a linear stiffness matrix input

and in this case it may be necessary to iterate the stiffness matrix until

compatibility between loads and stiffness is achieved. It may be necessary to vary

the stiffness matrix depending on what is critical to the analyses and associated

load levels. For example, the load levels and impact of cyclic degradation may be

quite different for ULS loading (where fewer bigger waves occur) when compared to

FLS loading.

4.10.5 An initial estimate of suction pile stiffness may be made using the methodology

published by Suryasentana et al. (2017) or Doherty et al. (2005) and

validated by finite element analyses as appropriate.

4.10.6 Detailed design will also require an estimate of the long-term performance of the

foundation to ensure that rotations and displacements remain within acceptable

limits. This aspect was investigated by Zhu et al. (2017) for response of

suction caissons in single-layer and layered seabeds and an expression for

accumulated rotation is provided along with the required calibration parameters

depending on soil conditions and relative layer thicknesses. The current work has

focussed on uni-directional loading and further development or validation is

required before applying the methodology to multi-directional loading.

4.10.7 An installation assessment can be performed using methodology such as that by

Andersen et al. (2008), Senders and Randolph (2009) or Houlsby and Byrne (2005). Key

considerations include:

- determining if suction assisted installation is required (i.e. suction

installed); or whether the caissons will penetrate under the combination of

their own weight and the structure (i.e. may be considered as jacked);

- estimating heave of the soil plug during installation;

- potential for cavitation of water during suction installation; and

- potential mitigation measures and their impact on the foundation should

early refusal be experienced. Such measures may include the use of ballast,

cycling of suction pressure or water injection.

4.10.8 If re-spudding of the caisson is required, due to refusal or some other installation

issue, the required offset distance from the refusal location should be considered

such that there is no significant impact upon the installed foundation.

4.10.9 Where experience in local or comparable soil or seabed conditions is not available,

then it may be prudent to perform field trials of suction caisson installation

before committing to the concept.

|