2.2.1 For a 15 ppm Bilge Alarm, the accuracy should

be within ± 5 ppm. The accuracy of a 15 ppm Bilge Alarm should

remain within the above limits despite the presence of contaminants

other than oil, and the power supply varying by 10% from the design

value i.e. in respect of electricity, compressed air, etc.

2.2.2 The sampling arrangement for the test rig

should be such that a representative homogeneous sample is obtained

under all conditions of operation and under all operational proportions

of oil content. The sample should be obtained from the full flow through

the 15 ppm Bilge Alarm, but when this is impracticable the sampling

arrangements shown in figure 4 in

part 1 should be used. Special care should be given to this stage

of the process and the validity of the resultant findings.

2.2.3 During the various tests, the response time

of the 15 ppm Bilge Alarm should be checked and it should be noted

whether alarms operate adequately when a pre-stated threshold is exceeded.

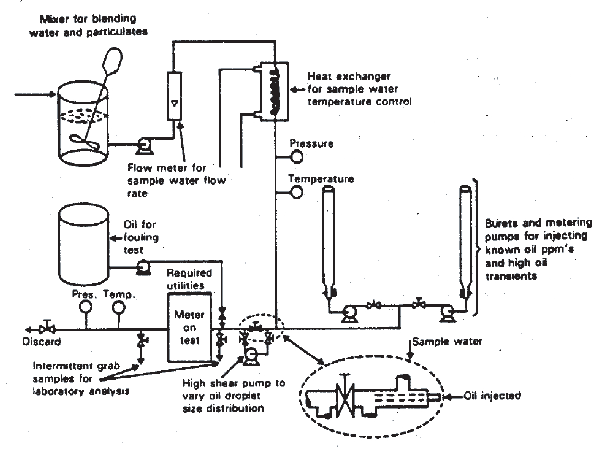

2.2.4 A diagrammatic arrangement of a test facility

for evaluating the performance of the 15 ppm Bilge Alarm is given

in figure 5. The accuracy

of the 15 ppm Bilge Alarm will be determined by comparing its readings

against a known flow of Test Fluid injected into a known flow of water.

The grab samples taken will be analysed in a laboratory by the methods

specified in part 4 of this annex. The results of the laboratory analysis

will be used for correction and to indicate sampling and test equipment

variability. The water flow rate will be adjusted so that the entire

Test Fluid-water flow passes through the 15 ppm Bilge Alarm, except

the intermittent grab sample stream. Special care should be given

to keep, continuously, a constant Test Fluid content in the water

that flows into the 15 ppm Bilge Alarm. The metering pumps should

be adjusted to deliver a nearly continuous quantity of Test Fluid.

If Test Fluid injection becomes intermittent at low concentrations,

the Test Fluid may be pre-mixed with water to provide continuous flow.

The Test Fluid injection point should be immediately up-stream of

the 15 ppm Bilge Alarm inlet to minimize time lags.

Diagrammatic arrangements of test facilities

2.2.5

Calibration test

The 15 ppm Bilge Alarm will be calibrated and zeroed as per

the manufacturer's instructions. It will then be tested with the three

test fluids "A", "B" and "C", as specified in paragraph 1.2.4 of part

1 of the annex, at the following oil concentrations in parts per million:

0, 15, and at the full scale of the meter. Each concentration test

will last for 15 min. Following each concentration test, the 15 ppm

Alarm will be run on oil-free water for 15 min and the reading noted.

If it proves necessary to re-zero or re-calibrate the 15 ppm Bilge

Alarm during this test, this fact will be noted.

2.2.6

Contaminant and colour test

The 15 ppm Bilge Alarm should undergo contaminant and colour

tests as follows:

-

.1 the 15 ppm Bilge Alarm should be run on a mixture

of clean water and 10 ppm Test Fluid "B" and reading noted;

-

.2 the water supply should be changed from 10

ppm Test Fluid "B" and clean water to 10 ppm Test Fluid "B" and water

contaminated with iron oxide in a concentration of 10 ppm;

-

.3 any shift in the 15 ppm Bilge Alarm reading

should be noted. The reading should be within the accuracy limits

specified in paragraph 2.2.1;

-

.4 the procedure specified in .2 and .3 above

should be repeated with iron oxide concentrations of 50 ppm and 100

ppm respectively;

-

.5 the 15 ppm Bilge Alarm should be run on a mixture

of clean water and 10 ppm Test Fluid "B" and its reading noted;

-

.6 the water supply should be changed from clean

water to very salt water (a solution of 6% common salt with clean

water);

-

.7 any shift in the 15 ppm Bilge Alarm reading

should be noted. The reading should be within the accuracy limits

specified in paragraph 2.2.1; and

-

.8 sufficient water should be available in the

mixing tank to ensure an effective test of not less than 15 min.

2.2.7

Sample pressure or flow test

The 15 ppm Bilge Alarm should be run on a 15 ppm Test Fluid

"B" sample. The water pressure or flow rate of the mixture should

be adjusted from one half normal, normal and twice normal. Any effect

of these changes on the 15 ppm Bilge Alarm ppm display reading should

be noted and recorded on the Certificate. This test may require modification

for 15 ppm Bilge Alarms with flow or pressure regulators or 15 ppm

Bilge Alarms designed to discharge into an ambient pressure sump.

2.2.8

Shut off tests

The 15 ppm Bilge Alarm should be run on a 15 ppm Test Fluid

"B" sample. The water and Test Fluid injection pumps should be shut

off. The 15 ppm Bilge Alarm will be left turned on with no other changes

made. After 8 hours, the water and Test Fluid injection pump should

be turned on and set to provide the mixture of 15 ppm. The 15 ppm

Bilge Alarm ppm display readings before and after each test and any

damage to the 15 ppm Alarm should be noted and recorded on the Certificate.

2.2.9

Utilities supply variation test

If the 15 ppm Bilge Alarm requires any utilities besides electricity,

it should be tested with these utilities at 110% and 90% of the design

figures.

2.2.10

Calibration and zero drift test

The 15 ppm Bilge Alarm should be calibrated and zeroed. A 15

ppm Test Fluid "B" sample will run through the 15 ppm Bilge Alarm

for eight hours and any calibration drift noted. Following this, the

15 ppm Bilge Alarm should run on oil-free water and any zero drift

noted and recorded on the Certificate. During this test grab samples

should be taken 0, 2, 4, 6, and 8 hours into the test schedule to

verify any calibration drift.

2.2.11

Response time test

The response time is to be taken for the 15 ppm Bilge Alarm

to give an alarm at 15 ppm oil concentration after the supply to the

15 ppm Bilge Alarm is changed from clean water to oily water having

a concentration of more than 15 ppm oil.

2.2.12 A specification of the instrument concerned

and a diagrammatic presentation of the test arrangements should be

provided and the following data should be reported.

-

.1 types and properties of Test Fluids used in

the tests (refer to part 1,

paragraphs 1.2.4 and 1.2.16 of this annex);

-

.2 details of contaminants used, in the form,

for example, of a supplier's certificate or laboratory test protocol;

and

-

.3 results of tests and analysis of grab samples.