2.2.1 Legislative requirements

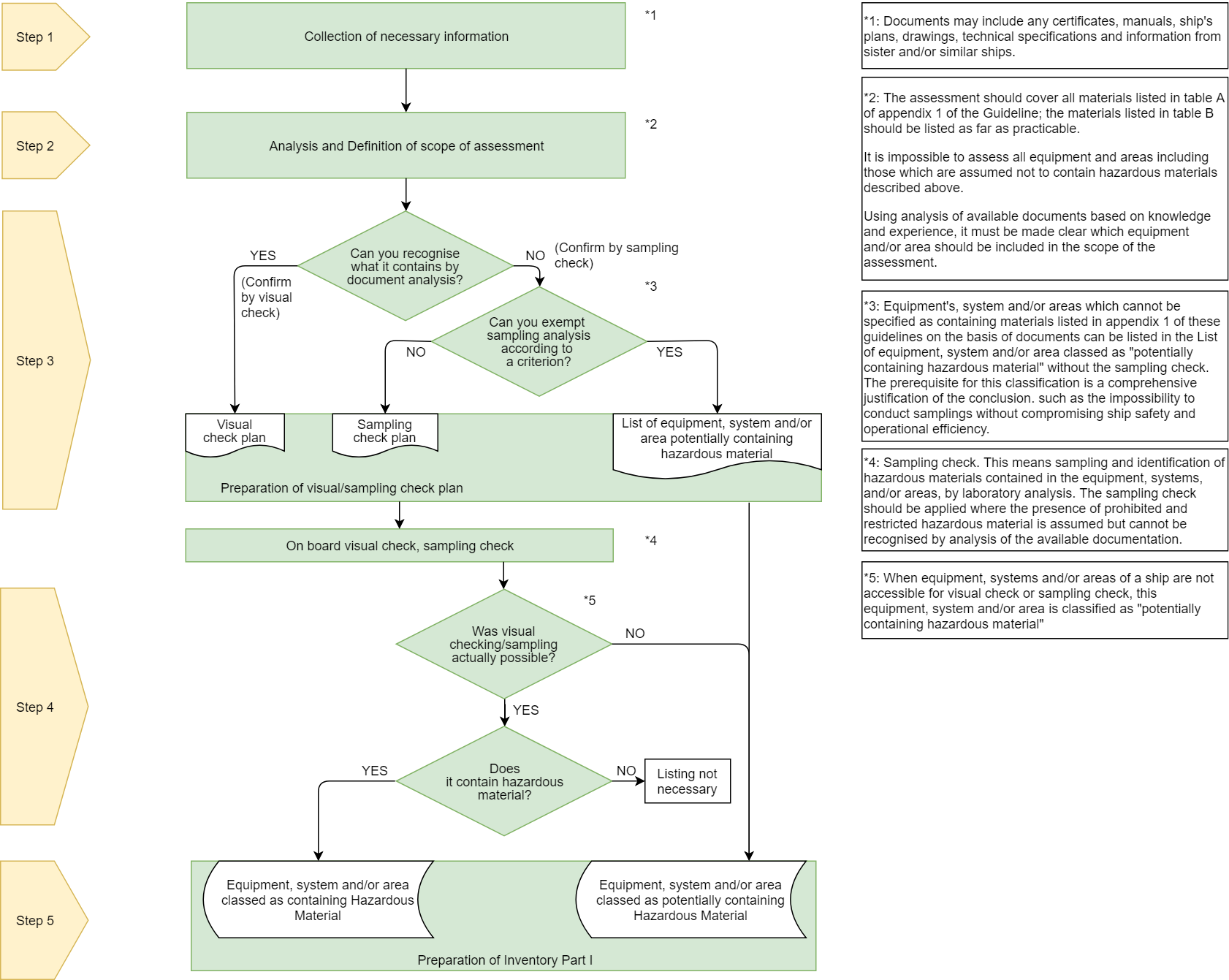

Figure 3.2.2 Flow diagram for developing Part I of the IHM for existing ships

2.2.2 Resolution MEPC.269(68) – 2015 Guidelines for the Development of the Inventory of Hazardous Materials

specifically states that these procedures ‘should be carried out by the shipowner,

who may draw upon expert assistance. Such an expert or expert party should not be

the same person or organisation authorised by the Administration to approve the

Inventory’. As such, in anticipation of LR acting as the recognised organisation to

the Administration, LR cannot compile the IHM and has no claim to the ownership of

the compiled IHM.

2.2.3 Advice for shipowners

In the absence of complete documentation of hazards contained within the ship’s

fitted equipment and structure, LR strongly recommends that a Hazardous Materials

Expert is used to compile the IHM.

2.2.4 LR maintains a list of independently approved Hazardous Materials Expert companies

who can assist with IHM compilation and hazardous materials sampling/testing

services. LR's approval process is detailed in the LR Approved Service Supplier

Procedures.

2.2.5 The latest version of the approval procedures publication (‘Procedures

for Approval of Service Suppliers’) is available from the Approvals section of LR’s

Class Direct website: https://www.lr.org/en/lr-approvals/. Simply search for ‘Hazardous’ and then refine

the results by selecting ‘Visual/sampling checks and testing for hazardous

materials’ in the product group category.

2.2.6 The objective of the Procedures for Approval of Service Suppliers is to set basic

standards to assess the qualification of firms supplying sampling and assessment

services to owners regarding hazardous material contents in ships.

2.2.7 The procedures (for ‘Service suppliers engaged in visual/sampling checks and testing

for hazardous materials, such as asbestos, PCBs, tributyltins (TBTs) and CFCs on

board ships’) include the following sections:

- Extent of engagement;

- Extent of approval;

- Certification and documentation;

- Procedures;

- Supervision;

- Operators;

- Equipment and facilities;

- Sampling and analysis, protocols and test methods;

- Reporting.

Please contact your local LR office for full details.

2.2.8 Note, sampling only indicates the qualities of the batch sampled, enabling confidence

levels to be built about the entire population. The required level of confidence can

only be assessed on a case-by-case basis against legislative and other

requirements.

2.2.9 In order to ensure that the IHM compiled for an existing ship is in full compliance

with the HKC and/or EU SRR, the shipowner’s requirement for IHM compilation should

be held under a contract between the shipowner and an LR approved Hazardous

Materials Expert.

2.2.10 Subsequent LR approval, verification and certification (see LR’s ShipRight

Procedure to obtain IHM (Inventory of Hazardous Materials) certification)

should be undertaken under a contract between LR and the shipowner.