1.1.1 Lloyd’s Register’s verification requirements and procedures for new

construction have been devised using the regulations detailed by the documents

listed below, collectively referred to as PSPC-WBT (Performance Standard for

Protective Coatings for Dedicated Seawater Ballast Tanks in All Types of Ships and

Double-side Skin Spaces of Bulk Carriers) and PSPC-COT (Performance Standard for

Protective Coatings for Cargo Oil Tanks of Crude Oil Tankers) in this document. The

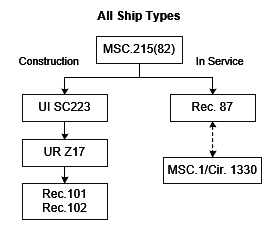

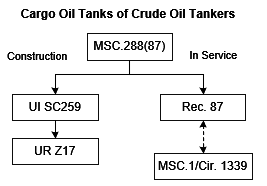

related standards and documents for reference refer to Figure 1.1.1 Documents for PSPC-WBT and Figure 1.1.2 Documents for PSPC-COT.

Figure 1.1.1 Documents for PSPC-WBT

Figure 1.1.2 Documents for PSPC-COT

1.1.2 MSC.215(82) refers to Performance Standard for Protective Coatings for Dedicated

Seawater Ballast Tanks in All Types of Ships and Double-side Skin Spaces of Bulk

Carriers.

1.1.3 UI SC223 is an IACS Unified Interpretation for Application of SOLAS Regulation

II-1/3-2 Performance Standard for Protective Coatings (PSPC) for Dedicated Seawater

Ballast Tanks in All Types of Ships and Double-side Skin Spaces of Bulk Carriers,

adopted by Resolution MSC.215(82). It makes all footnoted standards in MSC.215(82)

mandatory.

1.1.4 UR Z17 is an IACS Unified Requirement for Procedural Requirements for Service

Suppliers. It provides some requirements for auditing coating test laboratories.

1.1.5 Rec.101 refers to IACS Model Report for IMO Resolution MSC.215(82) Annex 1 ‘Test

Procedures for Coating Qualification’.

1.1.6 Rec.102 refers to IACS Model Report for IMO Resolution MSC.215(82) Annex 1 ‘Test

Procedures for Coating Qualification’, Section 1.7 – Crossover Test.

1.1.7 Rec. 87 refers to IACS Recommendation 87 – Guidelines for Coating Maintenance &

Repairs for Ballast Tanks and Combined Cargo/Ballast Tanks on Oil Tankers.

1.1.8 MSC.1/Cir.1330 refers to IMO Guidelines for Maintenance and Repair of Protective

Coatings and focusses on dedicated seawater ballast tanks of all types of ships and

double-side skin spaces of bulk carriers.

1.1.9 MSC.288(87) refers to Performance Standard for Protective Coatings for Cargo Oil

Tanks of Crude Oil Tankers.

1.1.10 UI SC259 is an IACS Unified Interpretation for Application of SOLAS Regulation

II-1/3-11 Performance Standard for Protective Coatings for Cargo Oil Tanks of Crude

Oil Tankers (PSPC-COT), adopted by Resolution MSC.288(87). It makes all footnoted

standards in MSC.288(87) mandatory.

1.1.11 MSC.1/Cir.1399 refers to IMO Guidelines on Procedures for In-service Maintenance and

Repair of Coating Systems for Cargo Oil Tanks of Crude Oil Tankers.