Section

3 Structural Design

3.1 General

3.1.1 Mitre gates and flap gates are to be considered as single plates with

vertical girders and horizontal stringers attached. Other configurations will be

specially considered.

3.1.2 For floating dock gates where the principal dimensions B and

D are such that the breadth B is the same as the span of the deck

beams (i.e. no intermediate support is provided) and the depth D is less than

6 metres, then the side shell and transverse bulkheads can be considered as a double

plate bulkhead.

3.1.3 Sufficient support is to be provided such as ensures 100 per cent end

fixity for all members.

3.2 Welding and structural details

3.3 Structural idealisation

3.3.1 For derivation of scantlings of stiffeners, beams, girders, etc. the formulae in the

Rules are normally based on elastic or plastic theory using simple beam models

supported at one or more points associated with an appropriate concentrated or

distributed load.

3.3.2 Apart from local requirements for web thickness or flange thicknesses, the stiffener,

beam or girder strength is defined by a section modulus and moment of inertia

requirement.

3.3.3 The effective geometric properties of rolled or built sections can be calculated

directly from the dimensions of the section and associated effective area of

attached plating. Where the web of the section is not normal to the attached

plating, and the angle exceeds 20°, the properties of the section are to be

determined about an axis parallel to the attached plating.

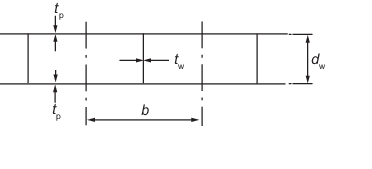

3.3.4 The geometric properties of rolled or built stiffener sections are to be calculated

in association with effective area of attached load bearing plating of thickness

tp mm and of width 600 mm or 40 tp mm,

whichever is the greater. In no case, however, is the width of plating to be taken

as greater than the spacing of the stiffeners. The thickness, tp,

is the actual thickness of the attached plating. Where this varies, the mean

thickness over the appropriate span is to be used.

3.3.5 The effective section modulus of a built section can be taken as:

where

|

a |

= |

the area of the face plate of the member, in cm2 |

|

dw |

= |

the depth, in mm, of the web between the inside of the face plate and

the attached plating. |

|

tw |

= |

the thickness of the web of the section, in mm |

|

A |

= |

the area, in cm2, of the attached plating,

see

Pt 2, Ch 2, 3.3 Structural idealisation 3.3.6.

If the calculated value of A is less than the face area a,

then A is to be taken as equal to a. |

3.3.6 The geometric properties of primary support members (i.e. girders,

transverses, webs, stringers, etc.) are to be calculated in association with an

effective area of attached load bearing plating, A, determined as

follows:

where

|

f |

= |

, but is not to exceed 1,0. Values of

this factor are given in Table 2.3.1 Load bearing plating

factor , but is not to exceed 1,0. Values of

this factor are given in Table 2.3.1 Load bearing plating

factor |

|

b |

= |

the actual width, in metres, of the load-bearing plating,

i.e. one-half of the sum of spacings between parallel adjacent members

or equivalent supports |

|

l |

= |

the overall length, in metres, of the primary support

member, see

Figure 2.3.2 Span points |

|

tp |

= |

the thickness, in mm, of the attached plating. Where this

varies, the mean thickness over the appropriate span is to be used. |

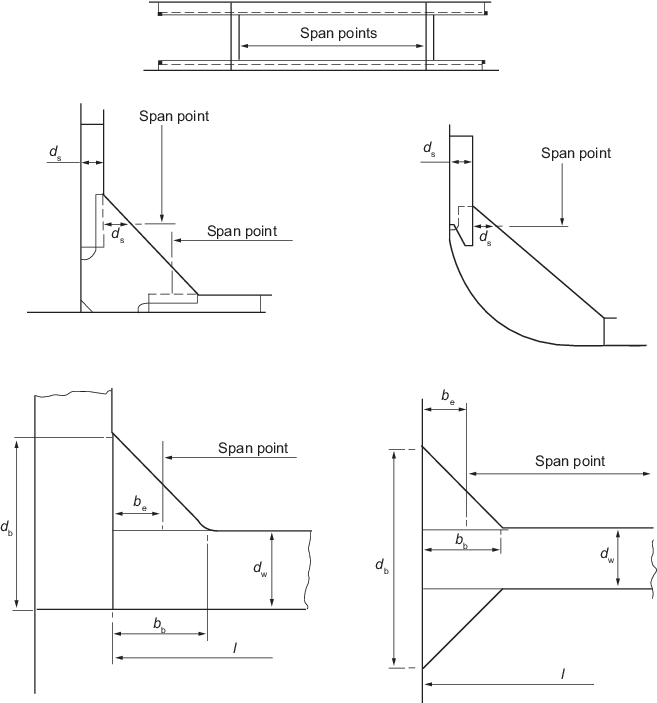

3.3.7 The effective length, le, of a stiffening member is generally less

than the overall length, l, by an amount which depends on the design of the

end connections. The span points, between which the value of le is

measured, are to be determined as follows:

- For rolled or built secondary stiffening members:

The span point is to be taken at the point where the depth

of the end bracket, measured from the face of the secondary stiffening

member, is equal to the depth of the member. Where there is no end

bracket, the span point is to be measured between primary member webs.

For double skin construction, the span may be reduced by the depth of

the primary member web stiffener, see

Figure 2.3.2 Span points.

- For primary support members:

The span

point is to be taken at a point distant from the end of the member,

where

See also

Figure 2.3.2 Span points.

3.3.8 Where the stiffener member is inclined to a vertical or horizontal axis and the

inclination exceeds 10°, the span is to be measured along the member.

3.3.9 Where it is assumed that the side shell and transverse bulkheads of a

floating dock gate are acting as a double plate bulkhead, the effective section

modulus of the combined section is to be calculated as follows:

where

|

dw |

= |

the breadth of the dock gate, B, in metres |

|

dt |

= |

the bulkhead plate thickness, in mm |

|

tp |

= |

the side shell plate thickness, in mm |

|

b |

= |

one-half of the sum of the spacings between adjacent

transverse bulkheads (including the ends of the floating dock gate) |

f is defined in Pt 2, Ch 2, 3.3 Structural idealisation 3.3.6

where l is taken as the depth D of the floating dock gate

See also

Figure 2.3.1 Double plate bulkhead

dimensions.

Figure 2.3.1 Double plate bulkhead

dimensions

Table 2.3.1 Load bearing plating

factor

|

f

|

|

f

|

| 0,5

|

0,19

|

3,5

|

0,69

|

| 1,0

|

0,30

|

4,0

|

0,76

|

| 1,5

|

0,39

|

4,5

|

0,82

|

| 2,0

|

0,48

|

5,0

|

0,88

|

| 2,5

|

0,55

|

5,5

|

0,94

|

| 3,0

|

0,62

|

6,0 and above

|

1,00

|

|

Note Intermediate values are to be obtained by linear

interpolation

|

Figure 2.3.2 Span points

|