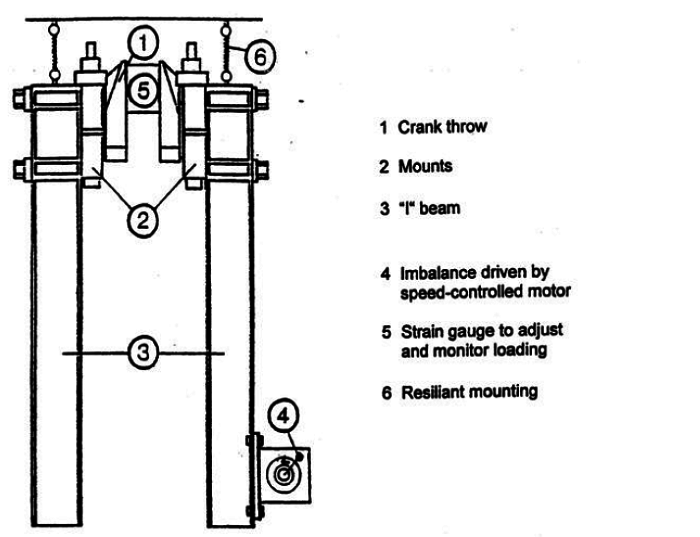

4.2.2 The applied load should be verified by strain gauge measurements on plain

shaft sections. It is also pertinent to check fillet stresses with strain gauge

chains.

Figure 2.4.1 An example of testing arrangement of the resonance tester for bending

loading

4.2.3 Clamping around the journals must be arranged in a way that prevents severe fretting

which could lead to a failure under the edges of the clamps. If some distance

between the clamps and the journal fillets is provided, the loading is consistent

with 4-point bending and thus also representative for the journal fillets.

4.2.4 In an engine, the crankpin fillets normally operate with an R-ratio slightly

above -1 and the journal fillets slightly below -1. If found necessary, it is

possible to introduce a mean load (deviate from R = -1) by means of a spring

preload.

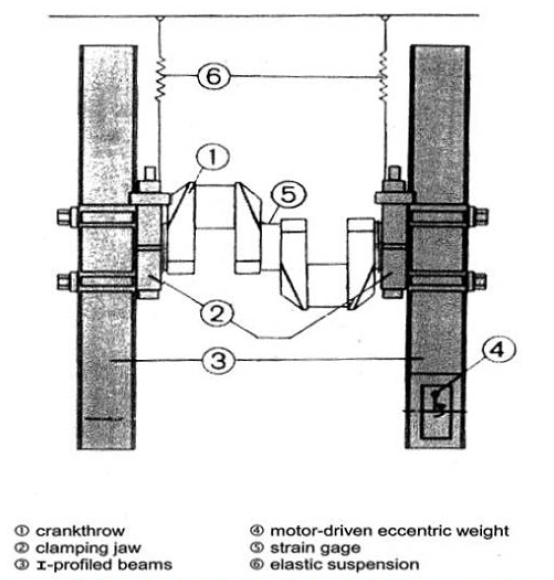

4.2.6 This sideways movement of the clamped-on weights can be reduced by having

two crank throws, especially if the cranks are almost in the same direction.

However, the journal in the middle will move more.

Figure 2.4.2 An example of testing arrangement of the resonance tester for torsion

loading with double crank throw section

4.2.7 Since sideway movements can cause some bending stresses, the plain portions of the

crankpins should also be provided with strain gauges arranged to measure any

possible bending that could have an influence on the test results.

4.2.8 Similarly to the bending case, the applied load shall be verified by strain gauge

measurements on plain shaft sections. It is also pertinent to check fillet stresses

with strain gauge chains as well.