Section

7 Corrosion additions

7.1 General

7.2 Net scantling approach

7.2.1 The net thickness of a structural element is that required for structural

strength compliance with the design basis. The corrosion addition for structural

elements is derived independently of the net scantling requirements. This approach

clearly separates the net thickness from the thickness added to address the

corrosion that is likely to occur during the in-operation phase. This approach

enables the status of the structure with respect to corrosion to be clearly

ascertained throughout the life of the unit. See

Figure 3.7.1 Example calculations of

corrosion additions.

7.2.2 The net thickness approach distinguishes between local and global

corrosion. Local corrosion is defined as uniform corrosion of local structural

elements, such as a single plate or stiffener. Global corrosion is defined as the

overall average corrosion of larger areas such as primary support members and the

hull girder.

7.3 Corrosion additions

7.3.1 The corrosion additions specified in this sub-Section are applicable to

each of the two sides of a structural member and are given as a corrosion rate. The

corrosion rate for each of the two sides of a structural member is specified in

Table 3.7.1 Corrosion rate for one side of

structural member. However, consideration

will be given to alternative corrosion rates if these are contractually agreed

between the Owner and Shipyard.

7.3.3 The corrosion rates for cargo and ballast water tanks given in Table 3.7.1 Corrosion rate for one side of

structural member assume the tanks will

spend 50 per cent of the time empty and 50 per cent of the time full over the unit

design life and that the ballast tank is fitted with effective anodes. Where

alternative regimes for individual tanks are specified, the corrosion rate may be

adjusted by [percentage time empty/50] x corrosion rate from Pt 4, Ch 3, 7.4 Scantling compliance 7.4.6. The percentage time empty is not to be

taken as less than 25 per cent.

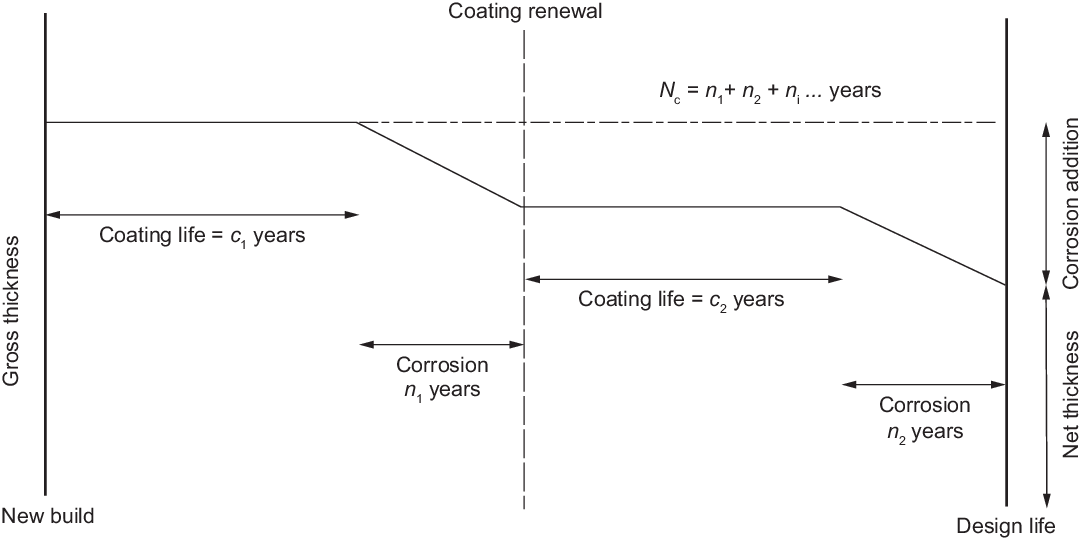

7.3.4 The default coating life is to be taken as 15 years. Alternative

corrosion additions may be derived using the general principles shown in Figure 3.7.2 Generic example unit life

cycle where an alternative coating

life is specified.

7.3.5 To address the risk of pitting corrosion, the gross thickness of the

bottom plating of tanks is not to be less than:

|

tgrs |

= |

6 + Nt (20tc1+

tc2) |

where

|

Nt |

= |

number of years between surveys (not to be taken as less than 5

for new builds or 2,5 for conversions) |

tc1 and tc2 are defined in Pt 4, Ch 3, 7.3 Corrosion additions 7.3.2. tc1 is the value for the

side of the structural member within the tank.

- Explanatory note:

- This requirement ensures that there is sufficient bottom

plating thickness remaining at thickness measurement survey so that pitting

corrosion should not lead to loss of barrier integrity between

inspections.

7.4 Scantling compliance

7.4.2 The net section modulus, moment of inertia and shear area properties of

local support members are to be calculated using the net thicknesses of the attached

plate, web and flange.

7.4.3 The net section properties, shear area and section modulus of primary

support members are to be calculated using the net thicknesses of the attached

plate, web and flange plus half of the applicable corrosion addition specified in

Pt 4, Ch 3, 7.3 Corrosion additions.

7.4.4 The net scantlings described in this sub-Section are related to gross

scantlings as follows:

- for application of the minimum thickness requirements, the gross

thickness is obtained from the applicable requirements by adding the full

corrosion additions specified in Pt 4, Ch 3, 7.3 Corrosion additions;

- for plating and local support members, the gross thickness and

gross cross-sectional properties are obtained from the applicable

requirements by adding the full corrosion additions specified in Pt 4, Ch 3, 7.3 Corrosion additions;

- for primary support members, the gross shear area, gross

section modulus and other gross cross-sectional properties are obtained from

the applicable requirements by adding one half of the relevant full

corrosion additions specified in Pt 4, Ch 3, 7.3 Corrosion additions;

- for application of buckling requirements, the gross thickness

and gross cross-sectional properties are obtained from the applicable

requirements by adding the full corrosion additions specified in Pt 4, Ch 3, 7.3 Corrosion additions.

7.4.5 Any additional thickness specified by the Owner as Owner’s extra margin

is not to be included when considering compliance with this Section.

7.4.6 The corrosion allowance to be deducted from the gross scantlings prior

to the compliance assessment is given in Table 3.7.2 Corrosion allowance to be

deducted from the gross scantlings prior to the compliance assessment.

Table 3.7.1 Corrosion rate for one side of

structural member

| Compartment type

|

Structural member

|

Corrosion rate tc1,

tc2(mm/year)

|

| Ballast water and

preload tanks (see Note 6)

|

within 3m below top of tank,

see Note 1

|

0,15

|

| Elsewhere

|

0,1

|

| Cargo oil tank

(see Note 3)

|

within 3m below top of tank,

see Note 1

|

0,125

|

| Bottom of tanks

|

0,125

|

| Elsewhere

|

0,075

|

| Exposed to

atmosphere

|

Weather deck plating

|

0,1

|

| Other members

|

0,075

|

| Exposed to sea

water (see Notes 6 and 7)

|

Shell plating

|

0,075

|

| Legs of self-elevating

units

|

0,075

|

| Exposed to sea bed and

seawater

|

Legs, footings, mats of

self-elevating units

|

0,2 (see Note 8)

|

| Fuel

and lubricating oil tank see (see Note 4)

|

0,05

|

| Fresh

water tank

|

0,05

|

| Slop

tanks

|

0,15

|

| Void spaces, see Note

2

|

Spaces not normally accessed,

e.g. access only via bolted manhole openings, pipe tunnels, inner

surface of stool space common with a dry bulk cargo hold,

etc.

|

0,05

|

| Dry spaces

|

Internals of machinery spaces,

pump room, store rooms, steering gear space, etc

|

0,05

|

| Hold space bounding membrane

liquefied gas tanks

|

side of hull structure within

hold space where there is environmental control such as

inerting

|

0

|

|

Note 1 This is only

applicable to cargo tanks and ballast tanks with weather deck as

the tank top.

|

|

Note 2. The

corrosion rate on the outer shell plating in way of a pipe

tunnel is to be taken as for a water ballast tank.

|

|

Note 3. 0,05 mm/year

is to be added to the plate surface exposed to ballast for the

plate boundary between water ballast and heated cargo oil tanks.

0,03 mm/year is to be added to each surface of the web and face

plate of a stiffener in a ballast tank and attached to the

boundary between water ballast and heated cargo oil tanks.

Heated cargo oil tanks are defined as tanks arranged with any

form of heating capability.

|

|

Note 4. 0,07 mm/year is to be added to the plate surface exposed to

ballast for the plate boundary between water ballast and heated

fuel oil tanks or lube oil tanks.

|

|

|

|

Note 6. The

corrosion rates indicated assume effective anodes are fitted to

the steel boundary.

|

|

Note 7. Additional

corrosion allowance in the splash zone is recommended.

|

|

Note 8. Additional

margins greater than those indicated in the table may be

required where the members are subject to high corrosion/wear

rates.

|

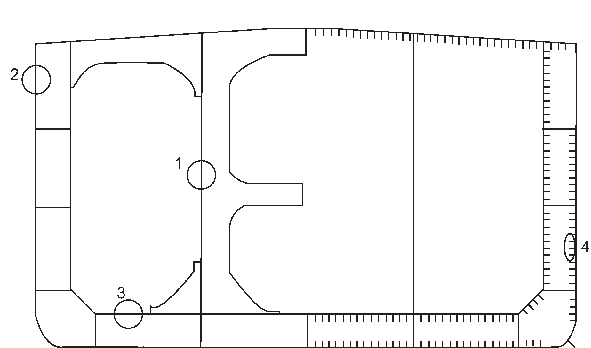

1 Longitudinal bulkhead plating

2 Side shell plating (within 3 m below top of tank

3 Cargo tank bottom plating

4 Stiffeners in ballast water tank

Note This example assumes that the

tanks will spent 50 per cent of the time empty and 50 per cent of the time full

over the unit design life.

Figure 3.7.1 Example calculations of

corrosion additions

Figure 3.7.2 Generic example unit life

cycle

Table 3.7.2 Corrosion allowance to be

deducted from the gross scantlings prior to the compliance assessment

| Assessment

|

Stress

calculations

|

Buckling capacity calculations

|

| Minimum

thickness

|

Thickness

|

|

N/A

|

| Local strength (plates, stiffeners, and hold frames)

|

Thickness/sectional properties

|

|

N/A

|

| Stiffness/proportions

|

|

|

| Primary

support members

|

Thickness/sectional properties

|

0,5

|

N/A

|

| (Prescriptive)

|

Stiffness/proportions of web and flange

|

|

|

| Strength

|

Global coarse

mesh

|

0,5

|

|

| Local fine

mesh

|

|

| Fatigue

|

Global coarse

mesh

|

0,25

|

N/A

|

| Local fine

mesh

|

0,5

|

| Sloshing

|

Sloshing

|

|

|

| Fracture

|

Global coarse

mesh

|

0,25

|

N/A

|

| Local extremely

fine mesh

|

0,5

|

| Ultimate

strength

|

Ultimate

strength

|

0,5

|

0,5

|

|

Note For the

assessment, the gross scantling used is not to include any

Owner’s extra.

|

|