Section

1 Verification requirements

1.1 Verification before coating application is started

1.1.1 Primary surface preparation and shop primer is the first coating

application process. Before primary surface preparation and shop primer, the

shipyard shall compile the CTF for pre-job agreement and submit it to LR Surveyors

for review. The TPA shall be agreed and signed by three parties, which are

shipowner, shipyard and coating manufacturer, before the CTF for pre-job agreement

is submitted to LR Surveyors. The contents of the CTF and required action refer to

Table 2.1.1 Checklist of the CTF for pre-job agreement.

Table 2.1.1 Checklist of the CTF for pre-job agreement

| No

|

Items

|

Activities by three parties

|

Activities by LR

|

Remark

|

| 1

|

TPA

|

Agree and Signature

|

Review

|

|

| 1.1

|

IMO PSPC applied area (IMO PSPC

Tank/Space Description and Drawings)

|

|

|

Some vessels may include

some spaces which could be mistaken to be within the scope of PSPC;

for example, some non-bulk carriers include double-side skin spaces

(DSSS). The tank arrangement drawings are recommended to be provided

for these vessels.

|

| 1.2

|

English to be used for

documentation

|

|

|

Sometimes the documents are written in

two languages. There could be a difference between the two

languages. The TPA should specify that English will prevail.

|

| 1.3

|

The selected coating system and shop

primer

|

|

|

Winter grade coatings should be

specified if they are used.

|

| 1.4

|

Coating Inspector(s) appointment

|

|

|

|

| 1.5

|

Assistants to the Coating

Inspector(s)

|

|

|

|

| 1.6

|

Copy of certificates of the Coating

Inspector(s)

|

|

|

The certificates shall be

valid.

|

| 1.7

|

Quality control process

|

|

|

Include: Inspection items, who will

carry out inspection and inspection standards.

|

| 1.8

|

Detailed requirements of coating

application and inspection

|

|

|

Include: Surface preparation and

coating application requirements for both hull structure and

out-fittings, reference standards, inspection notice, coating log

forms.

|

| 1.9

|

Settlement of disputes

|

|

|

Provide a procedure to settle the

disputes.

|

| 1.10

|

Non-conformity report issuing and

closing

|

|

|

Provide a procedure to

issue and close non-conformity reports.

|

| 1.11

|

Health and safety

|

|

|

Not mandatory, but should be addressed

in the CTF.

|

| 2

|

Copy of Type Approval Certificates for

main coatings and shop primer

|

|

Review

|

Weldable certificate of shop primer

shall also be provided. If winter grade main coatings are used,

their Type Approval Certificate shall also be provided.

|

| 3

|

Copy of PTDS for main coatings and shop

primer

|

|

Review

|

Some manufacturers have an application

procedure which shall also be provided.

|

| 4

|

Copy of Safety Data Sheet (SDS) for

main coatings and shop primer

|

|

Only for information

|

SDSs for both Part A and Part B for all

PSPC paint system components shall be provided by paint

manufacturers.

|

| 5

|

Procedures for in-service maintenance

and repair of coating system

|

|

Review

|

In compliance with MSC.Circ.1330

(PSPC-WBT) or MSC.Circ.1399 (PSPC-COT).

|

1.1.2 Some shipyards may have different formats for the CTF. But the contents listed in the

above checklist should be similar and comply with the

MSC.215 or MSC.288 requirements.

1.1.3 IMO PSPC applied area shall be in accordance with MSC.215(82) – PSPC-WBT or

MSC.288(87) – PSPC-COT.

1.1.4 The selected coating system shall have an LR Type Approval Certificate. The shop

primer shall be approved by Lloyd’s Register for weldability. Certificates shall be

confirmed to be valid. The details are held in the LR Approvals database.

1.1.5 A qualified Coating Inspector(s) shall be appointed. If there is to be more than one

Coating Inspector, there should be a clear definition of authority and

responsibilities for each Coating Inspector.

1.1.6 If the Coating Inspector(s) requires assistance from other persons to perform part of

the inspections, those persons shall perform the inspections under the Coating

Inspector’s supervision and shall be trained to the Coating Inspector’s

satisfaction. Training records shall be available for verification.

1.1.7 Validity of qualification certificates of the Coating Inspector(s) is confirmed by

the Surveyor. Coating Inspectors should be certified to NACE Coating Inspector Level

2, FROSIO Inspector Level III, or equivalent as verified by LR.

1.1.8 The quality control process and detailed requirements of coating application and

inspection shall at least comply with PSPC-WBT or PSPC-COT, respectively. Any

additional requirements of the coating supplier, Flag, Class or Owner can also be

included.

1.1.10 The shipyard is responsible for implementation of national regulations to ensure the

health and safety of individuals and to minimize the risk of fire and explosion.

1.1.11 PTDSs are checked in compliance with LR Type Approval Certificates and PSPC-WBT or

PSPC-COT respectively.

1.1.12 SDSs are available for information.

1.1.13 Procedures for in-service maintenance and repair of coating system shall

be prepared by the paint maker in compliance with the guidelines – MSC.Circ.1330 for

PSPC-WBT and MSC.Circ.1399 for PSPC-COT.

1.1.14 All interpretations shall be in compliance with SC223 and SC259 respectively.

1.1.15 For the shipyard who intend to retain the intact shop primer during block

blasting, an initial shop priming line audit shall be carried out by LR Surveyor(s).

The Approved Inspector should participate in the shop priming line audit process as

early as possible after being appointed. The Approved Inspector will then be

included as a signatory in the audit process. It may also be decided that the main

coating supplier participates in the audit process. The audit will be recorded in

the form – Figure 2.1.5 Shop priming plant

verification checklist. A different form may be used to record the audit.

1.1.16 If the shop priming line cannot be accepted by the LR Surveyor(s), the intact shop

primer should be 100 per cent fully removed by blasting to Sa 2½ during block

blasting.

1.2 Verification during coating application

1.2.1 The qualification of the Coating Inspectors shall be verified. For ‘Approved

Inspectors’ unknown to Lloyd’s Register, on-site verification will be required as

early as possible. For inspectors known to LR, spot check verification is

acceptable.

1.2.2 LR will record their monitoring verification details in the LR PSPC Checklists, Form

1215 (WBT and COT).

1.2.3 LR is to confirm that the shipyard’s QC system ensures that all calibration

certificates for inspection instruments are maintained up to date. If not, LR will

require all current certificates for review.

1.2.4 All sections of the Form 1215 shall be completed on a regular basis and be retained

for future reference.

1.2.5 There are five sections in Form 1215 which are used to record inspection

verification details. Table 2.1.2 Form 1215 vs inspection

processes

lists the five sections of Form 1215 with guidance for verification of the critical

inspection processes.

Table 2.1.2 Form 1215 vs inspection

processes

| No

|

Form 1215

|

Inspection processes

|

| 1

|

Primary surface preparation and shop primer application

|

Primary surface preparation and shop primer

|

| 2

|

Steel preparation

|

Sharp edge treatment after steel cutting

|

|

|

|

Sharp edge, welds and steel defects treatment at block

stage

|

| 3

|

Secondary surface preparation

|

Blast-cleaning of block

|

| 4

|

Surface preparation for

erection (or pre-erection) welds and damages

|

Surface preparation for pre-erection joints and

coating damages

|

| Surface preparation for erection joints and coating

damages

|

| 5

|

Main coating application

|

The 1st spray coat application of block

|

|

|

|

The 2nd spray coat application of block

|

|

|

|

The final coating inspection of block

|

|

|

|

The 1st spray coat application after erection or

pre-erection

|

|

|

|

The 2nd spray coat application after erection or

pre-erection

|

|

|

|

The final coating inspection after erection or

pre-erection

|

|

|

|

The tank final coating inspection before delivery

|

1.2.6 There are two types of Form 1215. They are Form 1215-WBT, which is applied to water

ballast tanks and double-side skin spaces, and Form 1215-COT, which is applied to

cargo oil tanks of crude oil tankers.

1.2.7 Monitoring of the coating inspection requirements, as required by the MSC.215(82) and

MSC.288(87) (Section 7.5), means checking, on a representative sampling basis, that

the inspectors are using the correct equipment, techniques and reporting methods, as

described in SC223 and SC259.

1.2.9 The LR Surveyor can choose to attend the inspection together with the three parties

or after the three parties complete the inspection items. The LR Surveyor can use

the data collected in the inspections to verify the reports issued by the Approved

Inspectors.

1.2.10 An appropriate level of inspections to be monitored by Surveyors should be agreed

during the kick-off meeting. It is recommended to include:

- Approximately 10 per cent of block inspections;

- A minimum of two hull stage tank inspections;

- A minimum of two pre-delivery tank inspections.

1.2.11 These inspections are recommended to include monitoring of the following critical

inspection processes:

- Block blasting;

- Block final coating inspection;

- Block 1st coat application;

- Block 2nd coat application;

- Surface preparation after erection and pre-erection (if applicable);

- Final coating inspection after erection and pre-erection (if

applicable);

- 1st coat application after erection and pre-erection (if applicable);

- 2nd coat application after erection and pre-erection (if applicable);

- Sharp edge treatment after steel cutting;

- Sharp edge, welds and steel defects treatment of block.

1.2.12 For the shipyard who intend to retain the intact shop primer, the verification of the

primary surface preparation and shop primer should be carried once for each

vessel.

1.2.13 For the shipyard who will 100 per cent fully remove by blasting the

intact shop primer to Sa 2½, the physical spot check of primary surface preparation

and shop primer can be omitted.

1.2.14 Non-conformances are to be documented in a Non-Conformance Report (NCR) and closed

off by the Approved Inspector after correction.

1.2.15 Non-conformances are considered non-compliances, if the shipyard or contractor

refuses to repair. Where the repair is specified to be carried out at a suitable

later date in the contract, the NCR will remain in place to act as a reminder until

the repair is successfully completed.

1.2.16 Routine requirements for repair after inspection will not be subject to an NCR if

repair is to be carried out immediately. Inspections resulting in rejection should

be detailed in the Preparation & Application Progress Report.

1.3 Verification after coating completion and prior to ship delivery

1.3.1 The shipyard shall complete the CTF for delivery in accordance with the PSPC-WBT and

PSPC-COT (only for cargo oil tanks of crude oil tankers) and ensure that all the

required documentation is included.

1.3.2 The CFT shall be submitted to the Surveyor for review prior to delivery.

Table 2.1.3 The checklist for the CTF for delivery provides a checklist for the review of the CTF for delivery.

Table 2.1.3 The checklist for the CTF for delivery

| No.

|

Item

|

Remarks

|

| 1

|

The CTF for pre-job agreement

|

The cover page should be signed by the

LR Surveyor.

|

| 2

|

The Amendment or supplementation of the

Tripartite Agreement (if any)

|

In some cases, the TPA has been

modified or supplemented; for example, if the Coating Inspector(s)

is replaced during the construction process.

|

| 3

|

Copy of Updated Certificates for

Coatings and Coating Inspectors (if any)

|

In some cases, the

certificates of the Coatings and Coating Inspectors may expire

during the construction process.

|

| 4

|

Copy of Updated PTDS and SDS (if

any)

|

The PTDS and SDS could be updated by

the paint manufacturer during the construction process.

|

| 5

|

Coating logs and work records

|

Confirm the forms used are the same as

specified in the TPA, the coating logs and work records are

completed, and the data is correct.

|

1.3.3 It shall be confirmed that all relevant reports have been signed by the Approved

Inspector(s) confirming that inspections have been carried out in accordance with

the MSC.215(82) and MSC.288(87) (only for cargo oil tanks of crude oil tankers), the

PTDS and all other agreed documentation. The Surveyor is also to confirm inspections

have been carried out to the satisfaction of the coating supplier's

representative.

1.3.4 Prior to delivery, the Surveyor is to confirm that a copy of the CTF has been given

to the Owner for placement on board. A copy of the completed CTF is to be retained

by LR for their records.

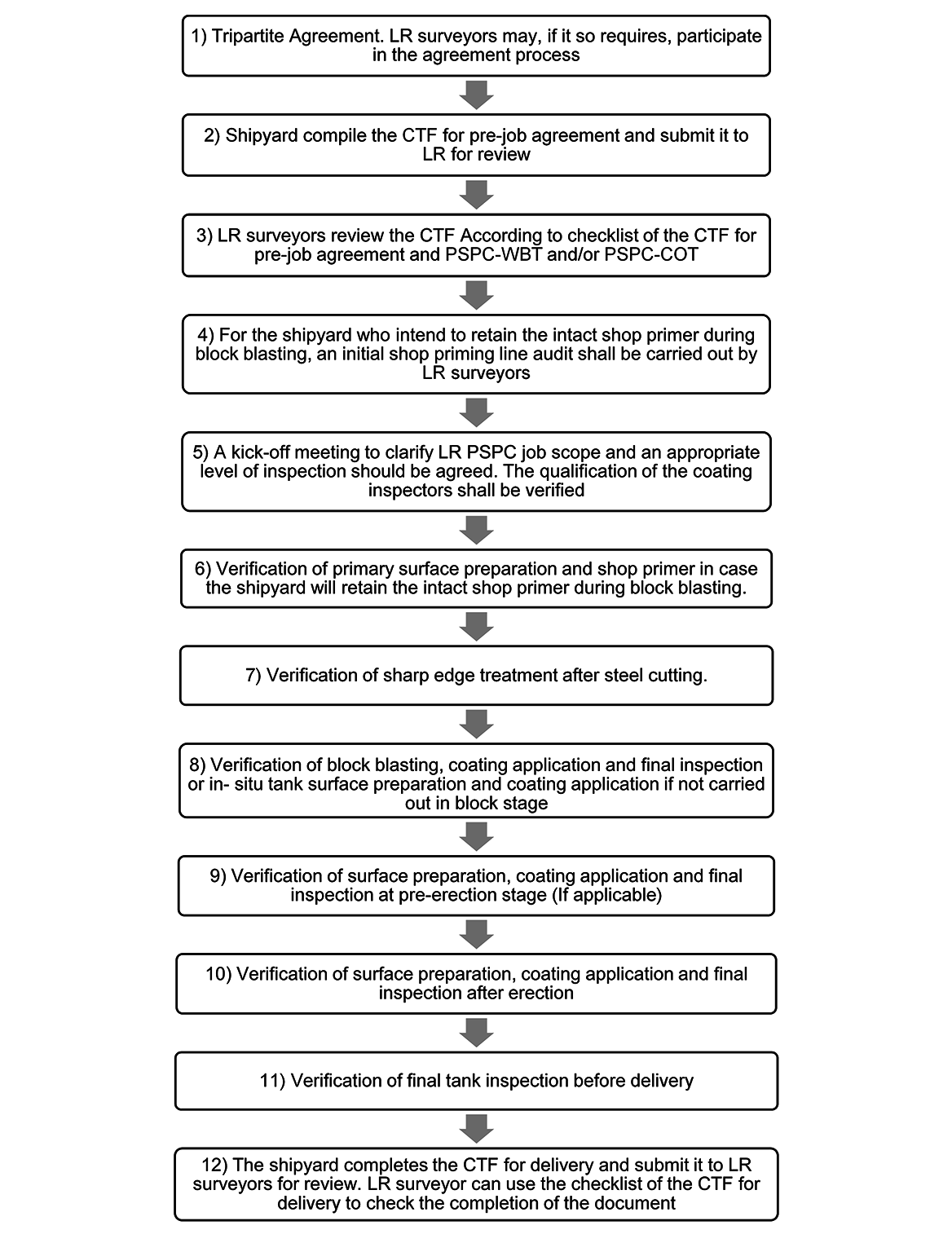

1.4 Verification Procedural Flow Chart

1.4.1 LR Verification Procedure Flow Chart refers to Figure 2.1.6 LR verification procedural

flow chart. The chart outlines the key stages of verification listed in the

PSPC-WBT and PSPC-COT requirements. LR verification requirements from Item 6 to Item

12 are summarized in Table 2.1.4 PSPC-WBT and PSPC-COT verification procedures.

Figure 2.1.6 LR verification procedural

flow chart

Table 2.1.4 PSPC-WBT and PSPC-COT verification procedures

| PSPC-WBT and PSPC-COT

verification procedures

|

|

|

| These Guidelines are

intended to assist in the LR verification and should be used

together with the working procedures agreed in the pre-job meeting.

LR is to check, on a sampling basis, that the Approved Inspector

uses the correct equipment, techniques and reporting

methods.

|

| Item

|

PSPC Requirement

|

Comment

|

| Before Start

|

| Primary

surface preparation and shop primer

PSPC

Requirements refer to Figure 2.1.5 Shop priming plant

verification checklist

|

| Sharp edge, welds and

steel defects treatment

|

| Removal of sharp edges

|

See comment

|

All sharp edges should be rounded to a minimum of 2 mm radius.

The PSPC requires 3 pass grinding; however, other methods will be

acceptable to LR provided the required standard is achieved.

|

| Removal of undercuts / laminations /

spatter / other steel defects

|

ISO 8501-3 Grade P2

|

|

| Removal of oil and grease

|

To be removed

|

Visual or Water droplet test – Water must wet out surface to be

tested. (UV lamp may be proposed but this method will only be

effective with certain types of oil and grease.)

|

| Surface

Preparation

|

| Blocks

|

Welds and corroded areas

|

Sa 2½ ISO 8501 – 1

|

The ISO 8503 Comparator method does not include

grade 30 μm to 75 μm. The profile will therefore be judged using the

appropriate medium grade comparator. Note that there are two types

of comparator, one for grit and one for shot.

|

| Profile 30 μm to 75 μm

|

| Damaged shop primer

|

ISO 8503-1 and 2

|

| Intact shop primer

|

See the coating’s Type Approval Certificate

|

The ‘Type Approval Certificate’ PTDS, LR primary surface

preparation audit and the PSPC will indicate the minimum required

standard of preparation.

|

| Block pre-erection & Tanks

|

Erection joints

|

St 3 ISO 8501 - 1 or

|

The coating supplier may require a minimum surface

profile after grinding / discing (see PTDS). If areas are to be

blasted, suitable procedures should be put in place to avoid over

blast damage.

|

| Sa 2½ ISO 8501 - 1

|

| Blast profile as above

|

| Damages

|

St 3 ISO 8501 - 1 or

|

If damages > 2% of the

total area then blasting to Sa 2½ is mandatory. The Hull Stage Tank

report requires that the damaged area be estimated and recorded.

For cargo oil tanks of crude oil tankers, damages > 3% in

the deck head or damages > 20% in the tank top then blasting

to Sa 2½ is mandatory.

If damages are to be blasted, a minimum area per damaged spot

must be agreed prior to the start of blasting and steps taken to

avoid over blast damage. Small isolated areas of damage should

be mechanically repaired. If widespread small damages are

present, then the entire affected area should be blasted to

avoid unnecessary over blast damage.

Note that over blast damage can be very difficult to see, hence

the importance in taking adequate steps for its prevention.

|

| Sa 2½ ISO 8501 - 1

|

| Blast profile as above

|

| Areas >25 m2

|

Sa 2½ ISO 8501 - 1

|

For areas greater than 25 m2 blasting to

Sa 2½ is mandatory.

|

| Blast profile as above

|

| Overlap areas

|

–

|

The agreed method of abrasive cleaning must be acceptable to the

coating supplier and ensure acceptable inter-coat adhesion.

|

| Soluble Salt test – Surfaces

|

ISO 8502-9 or NACE SP0508-2010 ≤ 50 mg/m2

|

The minimum number of tests per block or tank should have been

agreed at the pre-job meeting. Additional tests may be necessary

depending on conditions at the time of verification. PSPC requires a

minimum of one test per block. Sampling should be by Bresle Patch or

similar (Size A-1250, i.e. 1250 ± 13 mm2) and

conductivity measured in accordance with ISO 8502-9. Tests should

focus on areas most likely to be contaminated or on areas likely to

have been 'missed' during the cleaning process, e.g. behind bars,

tank floors, areas of corrosion, etc.

|

| PSPC-WBT and

PSPC-COT verification procedures (continued)

|

| These Guidelines are

intended to assist in the LR verification and should be used

together with the working procedures agreed in the pre-job meeting.

LR is to check, on a sampling basis, that the Approved Inspector

uses the correct equipment, techniques and reporting

methods.

|

| Item

|

PSPC Requirement

|

Comment

|

| After surface

preparation and before 1st coat

|

| Dust removal

|

ISO 8502-3 Rating 1 Class '3', ‘4' or '5'

|

The dust quantity rating is

not to exceed quantity rating 1 for dust classes ‘3’, ‘4’ or ‘5’.

Dust of lower classes is to be removed if visible on the surface

without magnification.

|

| Air Temp

|

°C

|

|

Q.C. to monitor conditions during and

after application until work is completed.

|

| RH

|

≤ 85%

|

|

| Steel Temp

|

(≥ 3°C higher than Dew Point)

|

|

| Dew Point

|

°C

|

|

| Drum identification and batch number to be

verified

|

To comply with the PSPC and the PTDS

|

Batch number of both the

base and curing agent to be recorded in the coating report. Normally

only one batch will be required for any single area. The Approved

Inspector must agree if more than two batches are to be used in any

area and record the reasons in the Preparation & Application

Record.

|

| Note: The PSPC

Standards do not specify ambient conditions during surface

preparation. It is important, however, to confirm that ambient

conditions required for coating are achieved before the cleaning

inspection is started. If ambient conditions do not meet dew

point/RH/surface and air temperature criteria, the quality of

surface preparation is likely to deteriorate before application of

the first full coat and stripe coat is complete.

|

| Coating

application should commence as soon as possible after surface

preparation has been accepted and must be completed before any

visible deterioration has occurred.

|

| Separate preparation and

cleaning inspections may be preferred to avoid re-cleaning if

surface preparation is not accepted. Depending on shipyard practice,

however, cleaning and surface preparation inspections may be carried

out simultaneously. Loose spatter should be removed before the

cleaning inspection. Cleaning inspections should always be carried

out from the tank top down.

|

| After 1st

Spray Coat application

|

Coatings to be free from:

- sags, runs and puddles

- craters

- pinholes

- bubbles

- holidays inclusions

- other defects

|

Steps must be taken to avoid similar problems in the

future

|

If defects are widespread

or if considered significant the cause must be urgently

investigated. If necessary, coating activities should be halted

until the cause of the defect is remedied.

|

DFT spot check

- flat surfaces

- longitudinal stiffeners

- transverse stiffeners and girders

- large brackets and primary supports around

openings

- areas inaccessible by airless spray

|

|

As considered necessary by

the Approved Inspector.

|

| Excessive thickness removed

|

|

To be repaired in accordance

with the supplier’s recommendations.

|

| Before

subsequent full coats and stripe coats

|

| Over coating interval

|

To comply with the PTDS

|

|

| Adequate ventilation in place

|

|

To comply with the Tripartite Agreement, PSPC and

PDS.

|

| Bulk contamination removed

|

| Dust removal

|

| Inclusions

|

| Air Temp

|

Inclusions to be removed and the coating repaired in accordance

with the supplier’s instructions.

|

| RH

|

| Steel Temp

|

| Dew Point

|

| Drum identification and batch no. verified

|

| PSPC-WBT and

PSPC-COT verification procedures (continued)

|

| These Guidelines are

intended to assist in the LR verification and should be used

together with the working procedures agreed in the pre-job meeting.

LR is to check, on a sampling basis, that the Approved Inspector

uses the correct equipment, techniques and reporting

methods.

|

| Item

|

PSPC Requirement

|

Comment

|

| After Stripe

Coating

|

Coatings free from:

- inclusions

- pinholes

- sags, runs and

puddles

- other defects

|

|

|

Film continuity

- welds

- edges

- cut outs

- areas inaccessible by

airless spray

|

|

Scallops and rat holes, etc. to be verified using a mirror as

necessary.

|

| The substrate

should not to be visible.

|

| The sequence of stripe

coats will normally be agreed at the pre-job meeting. It may be that

both stripe coats are applied between the first and second full

coats. Normally each full coat and intermediate stripe coat will be

a different colour from its substrate. If the second stripe coat is

to be applied after the second full coat it is normal practice to

apply the same colour as the last full coat. The extent of the

second stripe coat will be agreed at the pre-job meeting.

|

| Final Coat

Verification

|

Coatings to be free from:

- inclusions

- sags, runs and puddles

- craters

- pinholes

- bubbles

- other defects

|

Steps must be taken to

avoid similar problems in the future

|

1. Inclusions to

be removed and repaired according to the supplier’s

recommendations

|

| 2. Sags, runs and

puddles, if present, will normally be caused by poor application

technique. In exceptional cases the cause may be a batch or

formulation problem.

|

| 3. Defects such

as craters, pinholes and bubbles may be caused by surface

contamination or surface condition, ambient conditions, application

techniques or problems with the product. If present, the cause

should be investigated immediately to avoid re-occurrence in other

blocks or tanks.

|

|

|

| Depending on the extent of

the defect it may be necessary to halt production until the problem

can be resolved.

|

Film continuity

- flat surfaces

- welds

- edges

- cut outs

- areas inaccessible by airless spray

|

|

Scallops and rat holes, etc. to be verified using a mirror as

necessary.

|

| The substrate

should not to be visible.

|

DFT check:

- flat surfaces

- longitudinal stiffeners

- transverse stiffeners and girders

- large brackets and primary supports around

openings

- areas inaccessible by airless spray

|

SSPS-PA2:2004

|

LR will

confirm that the DFT procedures as detailed in PSPC Annex 3 are

being followed by the Approved Inspector. The Approved Inspector

will demonstrate to LR by a series of spot checks that measurements

are taken in the areas as required by the PSPC. The Approved

Inspector will also demonstrate that measured DFTs are in accordance

with the Type Approval Certificate, the PTDS and the PSPC.

Note: The PSPC refers to NDFT (Nominal Dry Film

Thickness) and a 90/10 rule. This means 90% of all thickness

measurements shall by greater than or equal to the NDFT, and

none of the remaining 10% shall be below 0.9 x NDFT (see

Table 1.1.5 of the PSPC). Excessive thickness must also be

avoided and be within the coating supplier's maximum values

quoted in the PTDS.

It is not the

responsibility of LR to verify the overall condition of the

block or tank or to carry out the verification without the

presence of the Approved Inspector.

|

| &

|

| PSPC Annex 3

|

| Excessive thickness

|

|

To be repaired in accordance

with the supplier’s recommendations.

|

Note: The Pre-delivery (Completion) Inspection should be carried out

after sea trials / ballasting whenever possible.

|