3.1.1 In practice,

substantial corrosion to the shell above the waterline is rare. The

wind and waterline of any vessel is always subject to corrosive conditions,

i.e. moisture and oxygen. Particular care needs to be taken to examine

this area when Docking or In-water Surveys take place. Other areas

commonly subjected to some degree of corrosion are the forefoot in

way of cable abrasion, portable plate fastenings, sacrificial anode

fastenings, keel plating in way of dock blocks, rudder and stabilizer

plating, and defective coverings on exposed decks.

3.1.2 Bathrooms,

WCs, galleys and sculleries are examples of compartments where corrosion

can develop. These spaces are usually lagged and lined, and invariably

have tiled or composition decks; ATU spaces and plenum chambers normally

have coated decks only. These areas should be specially examined and

special care needs to be taken to ensure that Periodical Surveys take

into account reports from the ship’s staff on any area which

retains liquid or suffers from high condensation during service.

3.1.4 Electro-chemical

corrosion affects aluminium and can occur where bimetallic joints

are present.

3.1.5 Stainless steel

can be subject to crevice corrosion when sea-water is present.

3.1.6 There have

been a number of instances where internal corrosion has occurred in

the bottom shell plating of oil tanks, especially in way of suction

strums which has been undetected during previous surveys, see

Ch 12 Pitting.

3.1.7 Affected plating

should be cropped and part renewed. Thicker plate and suitable bevelling

should be considered. If the corrosion is limited to a small area,

i.e. pitting corrosion, repair by welding is acceptable, but refer

to the limitations in Ch 12 Pitting.

3.1.8 The same defect

can occur beneath inlet and suction pipes, see

Figure 10.3.1 Corrosion in way of suction strum. Where this is found the same

repair method can be adopted, and the pipe modified to a larger end

opening.

Figure 10.3.1 Corrosion in way of suction strum

3.1.9 The defect

may be caused by high flow rate associated with insufficient corrosion

prevention system, or galvanic action between dissimilar metals.

3.1.11 A comprehensive

examination of the bottom of all oil tanks is to be carried out and

if any part of the bottom shell plating is found to be materially

reduced, special attention should be paid to corresponding positions

in all other tanks, see

Figure 10.3.3 Corrosion in bottom of oil tanker. Any defects are to be made good.

Figure 10.3.3 Corrosion in bottom of oil tanker

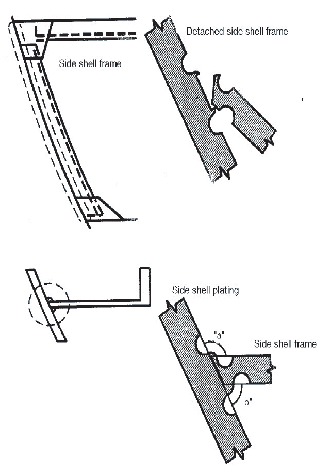

3.1.12 Localized

vertical grooving of the shell might be found adjacent to the fillet

welds in way of bulkhead and shell frame connections, and erection

butts, see

Figure 10.3.4 Corrosion of side shell frames.

Figure 10.3.4 Corrosion of side shell frames

3.1.13 Where grooving

extends over several frames, the report should be accompanied by sketches.

3.1.14 Isolated

fractures may be repaired by veeing-out and rewelding; isolated cases

of grooving may be repaired by build-up of welding to the Surveyor’s

satisfaction.

3.1.15 At the survey

of older ships, the condition of the shell plating directly below

side scuttles should receive attention as condensation or leakage

through the scuttles can cause heavy local corrosion. Heavy corrosion

is also liable to occur in plating beneath ship’s side discharges.

3.1.16 Parts of

the ship’s structure under boiler fronts, saltwater pumps and

any other locality where leakage from pipes, machinery items or continuous

condensation occurs should be specially examined.

3.1.17 The extent

of the renewal above should be determined carefully. If the renewal

plate (original thickness) is welded to thin plate (corroded plate),

it may cause stress concentration and further fracture. Protective

coatings should be applied.

3.1.19 Corroded

plating should be cropped and renewed. Protective coatings should

be applied.