10.1.1 The Surveyor

is to examine the stern seal and witness the tailshaft clearance gauge

readings being measured and note these for comparison with the previous

readings and the original measurements recorded immediately after

the shaft was fitted.

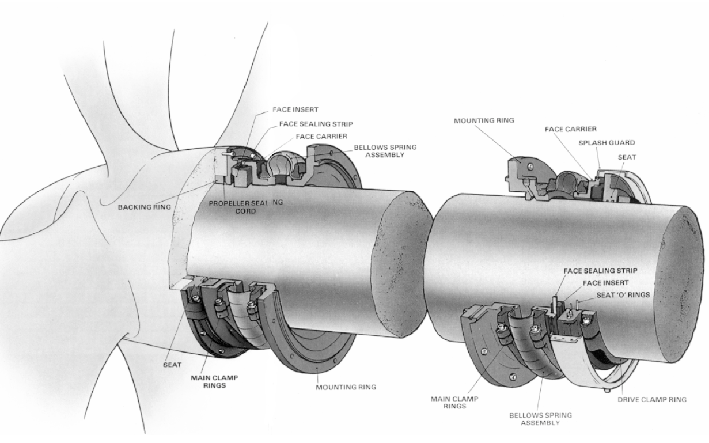

10.1.2 Seals for

oil lubricated stern bearings are designed to protect the stern bearing

against the ingress of sea-water and to retain the lubricating oil

within the bearing whilst being flexible enough to accommodate movement

of the shaft under varying loads and water pressures. The effectiveness

of a seal is dependent on the quality of the contact area between

the sealing ring and the liner. All signs of oil leakage should be

investigated.

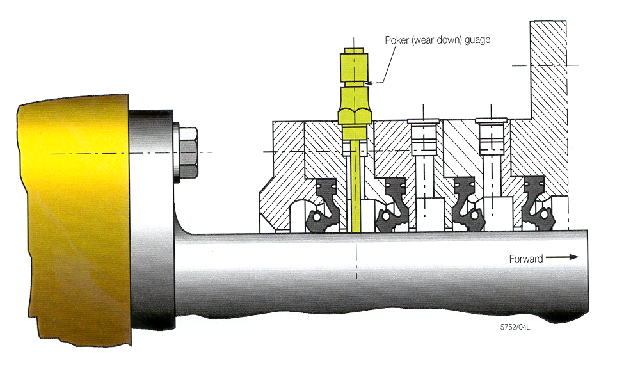

10.1.3 The wear-down

gauge is used to check the clearance of bearings. This relative measurement

provides an indication of wear quantified by a change of clearance

when compared with the original value. On a new ship the first (datum)

measurements are taken immediately the shaft is fitted. Since it is

important for all measurements that the weardown gauge is always used

in the same position, the line mark of the wear-down gauge is already

punchmarked on the casing of the aft seal during the first measurement.

For all measurements, care must be taken that the ‘O’

mark is always in the same position, which is punched into the circumference

of the flange of the liner. After each disassembly of the seal, new

measured values are determined. The gauge readings, when compared

with the original or datum readings, give an indication of wear on

the lower bearing surface and the shaft or liner when fitted. If the

lower gauge reading decreases, this may indicate wear of the bearing.

If the upper gauge reading increases and the increase is the same

as the decrease on the lower, this indicates wear on the bearing.

If the increase is greater than the lower gauge decrease, then this

indicates wear on the shaft or liner. These changes are considered

together with the Owner’s representative and a course of action

decided.

10.1.4 A forward

seal is fitted at the inboard end of the stern bearing and this should

also be examined.

Figure 7.10.1 Typical seal arrangements - I

Figure 7.10.2 Typical seal arrangements - II