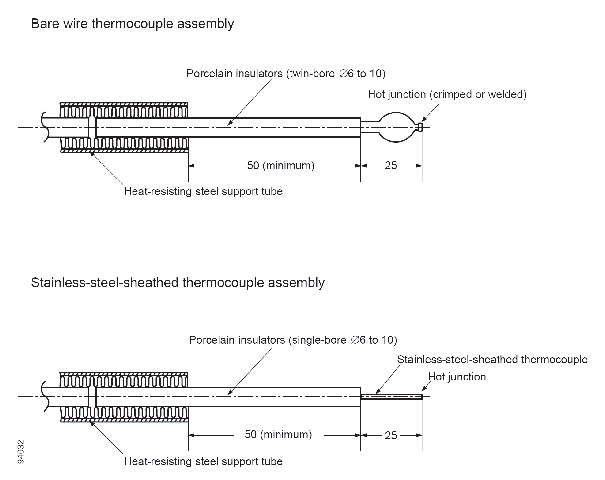

The furnace temperature should be measured by thermocouples

as shown in Figure 4. They

may be either thermocouples of bare-wire design or sheathed thermocouples

having an equivalent response time to that of bare-wire thermocouples.

The bare-wire thermocouples should have a wire diameter of between

0.75 and 1.00 mm and a welded or crimped junction. At least 25 mm

of wire should project from the insulation. Bare-wire thermocouples

should be checked at least after every 20 h of use, and stainless-steel-sheathed

thermocouples should be checked at least after every 50 h of use,

to establish their accuracy and sensitivity. If any doubt exists as

to their serviceability, they should be replaced.

Figure 4 Furnace thermocouple assembly