3.1

Pressure

transducers

The pressure transducers, signal conditioning, and recording

system should have a frequency response range which will measure the

impulsive pressures arising from cavitation. An upper frequency response

of about 5,000 Hz should be adequate for most purposes.

Corrosion

resistant pressure transducers should be used. Ideally the sensitive

membrane of the transducer should be flush with the outer hull surface

in order to avoid unwanted pressure harmonics. The design of available

transducers and fitting sometimes make this difficult to achieve in

practice.

3.2

System calibration

The pressure transducers and complete recording system should

be calibrated before and after the measurements.

3.3

Pressure

components

The hull surface pressure comprises two components. The first

is the direct radiated pressure from the propulsor and the second

is a self induced pressure resulting from the vibration of the transducer

mounted on the hull.

To separate these two components

it is necessary to measure the vibration at the pressure transducer

locations. This data, via suitable transformation methods, can be

used to estimate the self-induced pressure components in terms of

amplitude and phase at the transducer location.

3.4

Measurement

locations

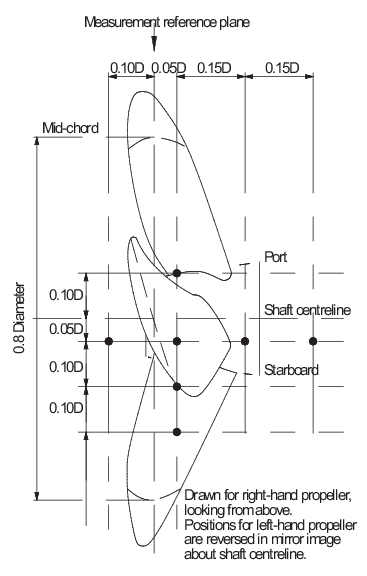

The number of pressure transducers should, ideally, be between

five and seven. For a right-handed propeller of diameter D, four pressure

transducers should be placed at 0.05D to starboard of the shaft centreline,

Figure 2.3.1 Propeller pressure measurement positions

. The longitudinal positions

should be in the measurement reference plane shown in

Figure 2.3.1 Propeller pressure measurement positions

, at intervals of 0.15D,

starting at 0.10D aft of the propeller tip plane. At the plane 0.05D

ahead of the propeller tips additional transducers may ideally be

placed at 0.10D to port and 0.15D and 0.25D to starboard. The mirror

image of this pattern should be applied for a left handed propeller.

For ships with significant areas of shell plating aft of the

propeller plane, pressure transducers may also be required to be located

at distances up to 2D aft of the propeller plane in line with the

principal tip vortex activity in the wake peak.

3.5

Phase marker

A phase marker or angular position indicator should be fitted

to the inboard shafting. It is convenient if this coincides with a

particular blade at a known angular position of the propeller.

3.6

Visual observation

Consideration should also be given to fitting viewing ports

in the hull to allow boroscopes or video cameras and stroboscopic

lighting to be used for observation in cases where severe cavitation

occurs.

Figure 2.3.1 Propeller pressure measurement positions