1.2.1 A meter designed to operate over a wide

range of oil content should measure the true oil content of the sample

entering the meter during each test within ±10 ppm or ±10%,

whichever is the greater, and testing should be performed in accordance

with the procedures detailed in paragraphs 1.2.5 to 1.2.18 of this

specification. The accuracy should remain within these limits in the

presence of contaminants other than oil and ±10% variations

from design criteria with respect to power (electricity and compressed

air).

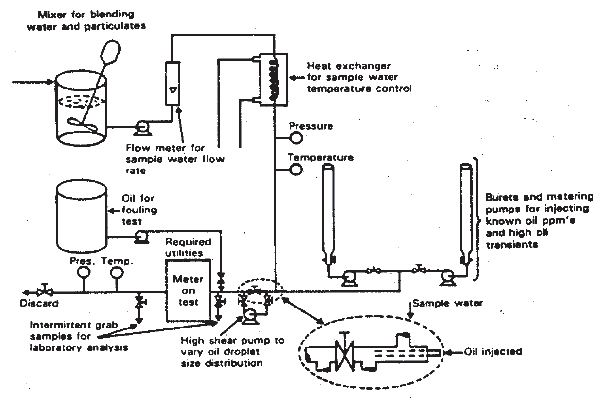

1.2.2 A diagrammatic arrangement of a test rig

for evaluating the performance of oil content meters is given in figure 1. The accuracy of the oil

content meter should be determined by comparing its readings with

a known flow of oil injected into a known flow of water. The grab

samples taken should be analysed in a laboratory by the method described

in paragraph 1.3 of this specification. The results of the laboratory

analysis will be used for correlation and to indicate sampling and

test equipment variability. The water flow rate should be adjusted

so that the entire oil-water flow passes through the oil content meter,

except the intermittent grab sample stream. Special care should be

given to keep, continuously, a constant oil content in the water that

flows into the meter. The oil and contaminant metering pumps should

be adjusted to deliver a steady flow. If oil injection becomes intermittent

at low concentrations, the oil may be premixed with water to provide

continuous flow, if absolutely necessary. The oil injection point

should be immediately upstream of the oil content meter inlet to minimize

time lags caused by the sample system. Wherever No.2 crude oil is

specified in particular tests, a similar crude oil may be substituted,

provided that the oil selected is used throughout the tests.

Test rig

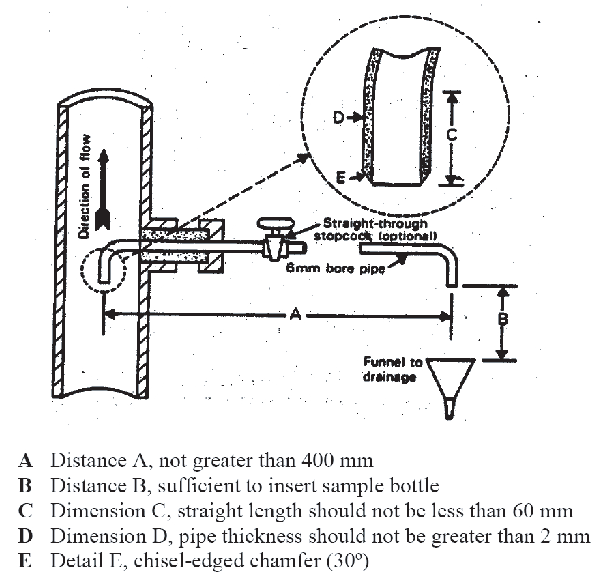

1.2.3 The sampling arrangement should be such

that a representative homogeneous sample is obtained under all conditions

of operation and under all operational proportions of oil content.

The sample should be obtained from the full flow through the meter,

but when this is impracticable, the sampling arrangements shown in figure 2 should be used. Special

care should be taken in collecting and preserving the sample to ensure

validity of the resultant findings.

Alternative sampling arrangement in test rig

1.2.4 Should the oil content meter incorporate

a filter or other device for removing solid contaminants from the

mixture to be tested, such a device should be regarded as part of

the oil content meter and be connected during all the tests. After

completion of the contaminant, tests referred to in paragraph 1.2.10

the device used to remove solid contaminants from the mixture should

be opened up and the residues inspected to ascertain that they do

not contain significant amounts of oil.

1.2.5

Calibration and zero test. The

oil content meter should be calibrated and zeroed in accordance with

the manufacturer's instructions. It should then be tested using the

No.2 crude oil at the following concentrations in ppm 0, 15, 50, 100,

200 and at intervals of 200 up to the maximum of the meter's highest

range. A complete calibration curve should be constructed. Each concentration

test should last for 15 min. After each concentration test the meter

should be run on oil-free water for 15 min and the reading noted.

The instrument should not be re-calibrated in spite of any movement

from zero.

1.2.6

Response tests. Different oil

types - After calibration in the previous test, the oil content meter

should be tested at concentrations of 15 ppm, 150 ppm and 90% of the

maximum full-scale with the following oils. Additional concentrations

may be added if required to construct a complete calibration curve

for each of the following oils:

|

For CRUDE OILS¹

|

|

Category of Oil

|

Categories Represented

|

Parameters Tolerance

|

| 1

|

Density low

|

Density*: 790.0-800.0

|

| Viscosity low

|

Kinematic viscosity**: 2.65 ±

5%

|

| Pour Point very low

|

Cloud point***: -2 ± 3°C

|

| General description mixed

base

|

|

| 2

|

Density medium

|

Density: 852.0-862.0

|

| Viscosity medium

|

Kinematic viscosity: 10.19 ±

5%

|

| Pour point low

|

Cloud point: -5 ± 3°C

|

| General description mixed

base

|

|

| 3

|

Density high

|

Density: 884.0-894.0

|

| Viscosity medium

|

Kinematic Viscosity: 12.9 ±

5%

|

| Pour point low

|

Cloud point: 5 ± 3°C

|

| General description

naphthenic

|

|

| 4

|

Density very high

|

Density: 947.0-957.0

|

| Viscosity very high

|

Kinematic Viscosity: 1246 ±

5%

|

| Pour point low

|

Cloud point: 29 ± 3°C

|

| General description

asphaltic

|

|

| 5

|

Density medium

|

Density: 839.0-849.0

|

| Viscosity high

|

Kinematic Viscosity: 3.96² ±

5%

|

| Pour point very high

|

Cloud point: 39 ± 3°C

|

| General description

paraffinic

|

|

| 6

|

Marine residual fuel oil RMG

35

|

RMG 35 Parameters as per ISO

8217:2010/Corr 1:2011 (tables 1 and 2)

|

Notes

1 Reference for these parameters is Institute of

Petroleum publication - Petroleum Measurement Paper No.8 - ISBN 0 85293 2.

2 This viscosity is recorded at 40°C due to this oil's

high pour point which renders the kinematic viscosity not measurable at 20°C.

* Density in kg/m3 at 15°C; this parameter is

reported by conversion using table 3 of the Petroleum Measurement Tables - ASTM D

1250-80.

** Kinematic viscosity (Cst) at 20°C.

*** Cloud Point in °C.

Note

Other oils covering the range of properties shown may be substituted if

those shown are unobtainable.

The characteristics of the oil and age of sample shall be

recorded. Samples used for approval must be less than 12 months old.

Following each test, the meter should be run on oil-free

water for 15 min and the meter reading recorded. Should the meter

reading at zero oil through put exceed the accuracy requirement, an

automatic cleaning device should be fitted to the instrument as standard.

If it is necessary to re-zero, recalibrate, or clean the meter between

tests, this fact and the time required to recalibrate or clean the

meter should be noted and recorded on the certificate.

1.2.7

White petroleum products. If

the meter is considered suitable for "white" petroleum products, it

should also be tested with the following products in a manner similar

to the tests set out in paragraphs 1.2.5 and 1.2.6:

If the meter is to be considered suitable for any of the category

C and D oil-like noxious liquid substances referred to in the list

contained in the unified interpretations to regulation 14 of Annex

II of MARPOL 73/78, it should also be tested against each such substance

for which approval is required, in a manner similar to the tests set

out in paragraphs 1.2.5 and 1.2.6. The high shear pump shown in figure

1 should be kept in operation at high speed during this test to assist

in dissolving the appropriate fraction of the substance in the water

stream.

1.2.8 If the meter is to be considered suitable

for an individual biofuel blend containing 75 per cent or more of

petroleum oil, it should also be tested against each such substance

for which approval is required, in a manner similar to the tests set

out in paragraphs 1.2.5 and 1.2.6. The high shear pump shown in figure

1 should be kept in operation at high speed during this test to assist

in dissolving the appropriate fraction of the substance in the water

stream.

1.2.9 Individual Biofuel blends should be tested

at 75 per cent and 99 per cent petroleum oil.

1.2.10

Response times. The oil content

meter should be run on oil-free water and zeroed. The oil injection

pump, set to 100 ppm No.2 crude oil, should be turned on.

The following response times should be recorded and included

on the certificate:

-

.1 time for first detectable reading;

-

.2 time to read 63 ppm;

-

.3 time to read 90 ppm; and

-

.4 time to read 100 ppm or for reading to stabilize

at maximum, the value (ppm) of which should be recorded.

Following this upscale test, the oil injection pump should be

turned off and the following response times should be recorded and

included on the certificate:

-

.5 time for the maximum reading to drop detectably;

-

.6 time to read 37 ppm;

-

.7 time to read 10 ppm; and

-

.8 time for reading to stabilize at minimum, the

value (ppm) of which should be recorded.

The response time of the meter, which should be taken as the

average of the response time recorded to read 63 ppm and the response

time recorded to read 37 ppm, should be less than 20 s.

1.2.11

Oil fouling and calibration shift

tests. Two tests using No.2 crude oil should be performed to

determine the effect of oil fouling on calibration shift. The first

test should be done with a 10% oil concentration and the second with

a 100% oil concentration.

For the 10% oil concentration test, the meter should initially

be running on oil-free water. The high capacity oil injection pump,

set to give 10% oil in water, should be turned on for 1 min and then

turned off.

For the 100% oil concentration test, the meter

should be running on oil-free water. The water should be turned off

and 100% oil turned on for 1 min. The oil should then be turned off

and the oil-free water flow resumed.

Care must be taken

in the design of the test equipment to ensure that the oil fouling

test results are not degraded by fouling of the sample piping external

to the meter.

The following response times should be noted

for both tests and recorded on the certificate:

-

.1 time for first detectable reading;

-

.2 time to read 15 ppm;

-

.3 time to read 100 ppm;

-

.4 time for reading to go off scale on the highest

range;

-

.5 time for reading to return back on scale on

the highest range;

-

.6 time for reading to return to 100 ppm;

-

.7 time for reading to return to 15 ppm; and

-

.8 time for reading to return to zero or stabilize

at minimum ppm reading.

If it is necessary to clean the meter after each oil fouling

test for it to return to a zero reading, this fact and the time required

to clean and recalibrate the meter shall be noted and recorded on

the certificate.

After successful completion of both oil

fouling tests, a 100 ppm mixture of No.2 crude oil should be introduced

and any calibration shift noted and recorded on the certificate.

1.2.12

Contaminant tests. The meter

should be run on contaminant test as follows:

-

.1 the contaminants should be mixed in the mixing

tank with clean water as follows:

not less than 270 ppm by weight of attapulgite (see note (a))

and 30 ppm by weight of iron oxides (see note (b)). Each material

should be mixed sequentially in the mixing tank to the following criteria:

-

.2 the meter should be run on a mixture of clean

water and No.2 crude oil of 15 ppm;

-

.3 the water supply should be changed from clean

water to contaminated water;

-

.4 any shift in the meter reading should be noted

in the certificate. The meter reading should be within the accuracy

limits specified in 1.2.1;

-

.5 the test specified in .2, .3, and .4 above,

should be repeated with oil concentrations of 100 ppm and 300 ppm;

and

-

.6 sufficient water should be available in the

mixing tanks to ensure an effective test period of not less than 15

min.

Notes:

(a) Attapulgite is a clay mineral with the chemical

formula (MgAl)5Si8O22(OH)44H2O

and is stable in both fresh and salt water. The test contaminant should have a

particle size distribution with about 30% of 10 microns or less and a maximum

particle size of 100 microns.

(b) The term "iron oxides" is used to describe black

ferrosoferric oxide (Fe3O4) with a particle size distribution

of which 90% is less than 10 microns, the remainder having a maximum particle size of

100 microns.

1.2.13

Air entrainment test

-

.1 The meter should be run on a mixture of water

and 15 ppm No.2 crude oil.

-

.2 Air should be injected into the test circuit

immediately before the sample pump or, in the absence of such pump,

immediately before any conditioning unit used to prepare the mixture

for measurement. Injection should be by needle having an orifice dimension

not exceeding 0.5 mm in diameter arranged in line with the sample

flow. The quantity of air injected should be 1% of the designated

flow rate of the sample pump or conditioning unit at the point of

injection. Air should be delivered to the system by direct injection

or pump via a suitable measuring device designed to permit a constant

controllable flow rate within ±10% of the required rate of

injection for an uninterrupted effective test period of not less than

15 min.

-

.3 Any shift in the meter reading should be recorded

on the certificate.

-

.4 The tests specified in points 1, 2 and 3 should

be repeated with an oil concentration of 100 ppm and 300 ppm respectively.

1.2.14

Oil particle size - shear pump test. The

meter should be run on a mixture of water and No. 2 crude oil of 100

ppm. The high shear pump, shown in figure

1, should be run at various speeds to provide a range of oil

particle size to the meter and on completion of this test the pump

should be stopped. Any effect of particle size on the meter reading

should be noted and recorded on the certificate. The purpose of this

test is to demonstrate that the meter's accuracy is not significantly

affected by the oil droplet size or by the degree of oil and water

mixing.

1.2.15

Temperature test. The meter

should be run on a mixture of water and No.2 crude oil of 100 ppm.

The water temperature should initially be set at 10°C and then

at 65°C. If the manufacturer's specification lists an operating

maximum water temperature of less than 65°C,the meter should be

run at that maximum temperature and this fact, together with any effect

of water temperature on the meter reading, should be recorded on the

certificate.

1.2.16

Sample pressure or flow test. The

meter should be run on a mixture of water and No.2 crude oil of 100

ppm. The water pressure or flow rate of the mixture should be adjusted

from one-half normal, to normal and to twice normal. Any effect of

these changes on the meter reading should be recorded on the certificate.

This test may require modification, depending on the flow characteristics

of the meter.

1.2.17

Shut-off test. The meter should

run on a mixture of water and No.2 crude oil of 100 ppm. The water

and oil injection pumps should be shut off and the meter left on with

no other changes made. After eight hours, the water and the oil injection

pumps should be turned on and set to provide a mixture of 100 ppm.

The meter readings before and after each test and any damage to the

meter should be recorded on the certificate. This test also determines

the proper functioning of the low flow shut-off and alarm.

1.2.18

Utility supply variation test. The

meter should be run on a mixture of water and No.2 crude oil of 100

ppm. The supply voltage should be increased to 110% of the nominal

value for one hour and then reduced to 90% of the nominal value for

one hour. Any effect on meter performance should be recorded on the

certificate.

If the operation of the meter requires any utilities besides

electricity, it should be tested with these utilities at 110% and

90% of the design figures.

1.2.19

Calibration and zero drift test. The

meter should be calibrated and zeroed in accordance with the procedures

in the manufacturer's instructions manual. A mixture of water and

No.2 crude oil of 100 ppm should be run through the meter for eight

hours and any calibration drift recorded on the certificate. Following

this, the meter should be run on oil-free water and any zero drift

recorded on the certificate.

1.2.20

Shut-down and re-energization test. The

meter should be shut down and de-energized for one week. It should

be turned on and started in accordance with the manufacturer's instructions.

After the suggested warm-up and calibration procedures, the meter

should be run for a period of eight hours, operating alternatively

for one hour on a mixture of water and No.2 crude oil of 100 ppm and

for one hour on oil-free water. After each step in the operation,

any zero or span drift should be recorded on the certificate. The

total time required to perform the manufacturer's suggested warm-up

and calibration should also be recorded on the certificate.

1.2.21

Reporting of test results. A

specification of the instrument concerned and a diagrammatic presentation

of the test arrangements should be provided to the Administration

by the manufacturer when applying for type approval and the following

data should be reported in the international metric system of units:

-

.1 types and properties of oils used in the tests;

-

.2 details of contaminants used, in the form,

for example, of a supplier's certificate or laboratory test protocol;

and

-

.3 results of tests and analysis of grab samples.

The recommendations of the manufacturer of the oil content meter

concerning the choice and application of cleansing agents used for

cleaning purpose should be recorded in the appendix to the type approval

certificate.

The size of the mixing tank should be specified

so as to allow a minimum "once through" effective test period of 15

min. Adequate arrangements should be made for in-tank mixing or recycling

to ensure a homogeneous mixture.