6.4.1 When carrying out inspections of these tanks,

particular attention should be paid to any cracking, deformation or

deterioration of coating.

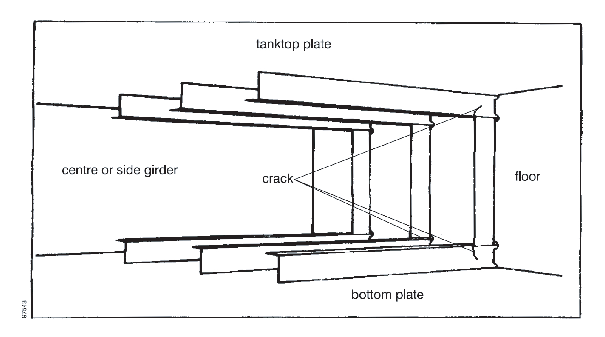

Cracking in bilge hopper and double bottom tanks

6.4.2 Cracks might be found at the intersections

of longitudinals and transverse members and at other locations as

follows:

-

.1

Intersections

of longitudinals and solid floors

Cracks may be found in the side, bottom and/or tanktop longitudinals

at intersections with solid floors or bilge hopper transverses. Cracks

also may be found in the floors or transverses occurring at the corners

of the slots cut for longitudinals.

-

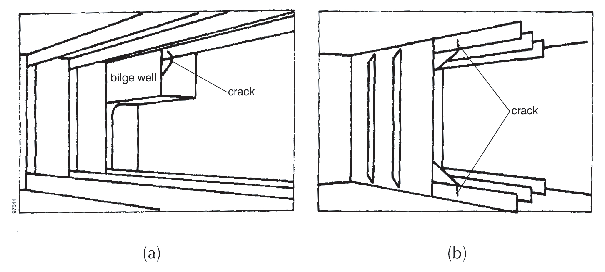

.2

Cracking

of longitudinals at areas of structural discontinuity

Longitudinals may be cracked at the ends of additional (partial)

side girders provided in the double bottom below cargo hold bulkheads

or side walls of bilge wells for cargo holds due to additional stress

concentration caused by the structural discontinuity at those connections.

-

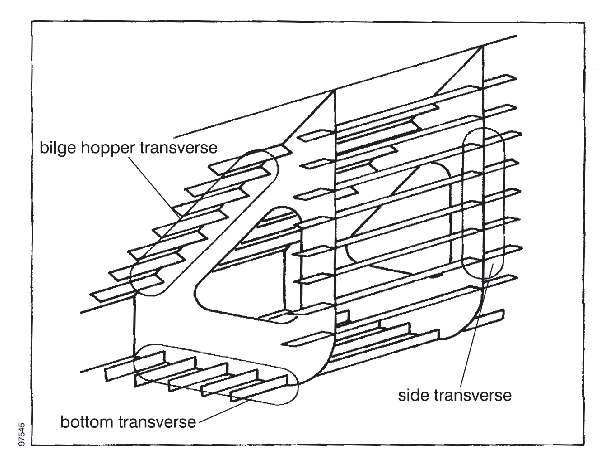

.3

Bilge

hopper transverse

Cracks may be observed in transverse webs in bilge hoppers initiating

from the slot openings for longitudinals and at the knuckled corners

of the lower ends of the hoppers.

Figure 17 Cracking in tanktop/bottom longitudinals

Figure 18 Cracking at the end connection with side walls of bilge well; Cracking

at the end of an additional girder

Figure 19 Check points in bilge hopper transverse

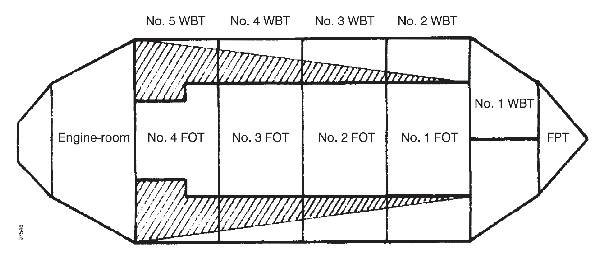

6.4.3 Corrosion must be carefully watched in the

inspection in water ballast tanks particularly in older bulk carriers

over 10 years of age. In general, the condition of the steel and protective

coatings will be in satisfactory condition much longer in the double

bottoms than in topside compartments. However, even double bottom

tanks will deteriorate in time due to the continual ballasting of

the ship.

-

.1

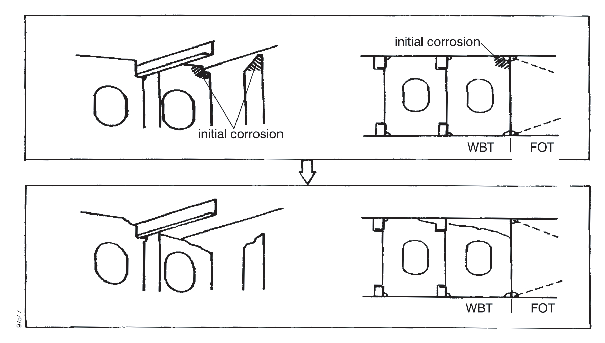

Corrosion

accelerated by heat

Since the late '70s, problems with heavy corrosion in double

bottom water ballast tanks adjacent to fuel oil tanks have appeared.

In some cases, the corrosion was worse in areas closer to the fuel

oil tank boundaries. In those ships, fuel oil tanks were installed.

The fuel oil heating system was adopted following changes to

the properties of fuel oil, mainly an increase in viscosity. Due to

economics, ship operators began to use low grade bunker oil which

needs heating in order to decrease the viscosity. In the beginning

of this trend, the temperature required in the fuel oil tanks was

not high enough to accelerate the corrosion of the steel in the adjacent

spaces. However, in recent years, the grade of bunker oil being used

requires the temperature in the tank to be 80°C or more. Such

temperature can accelerate corrosion of the steel in the tanks, particularly

in the vicinity of the boundaries of the fuel oil tanks.

-

.2

Areas under suction bell mouths

Bottom plates are often eroded under the suction bell mouths

in tanks. On drydocking of an older ship, the bell mouths should be

dismantled for examination of the condition of the shell plates below

the bell mouths.

Figure 20 Area where heavy corrosion by heat effect may be found (hatched

areas)

Figure 21 Progress of corrosion in water ballast tanks adjacent to FOT