4.0 Methods

of Test [7]

4.1 General

The following tests should be conducted for each type of

nozzle. Before testing, precise drawings of parts and the assembly

should be submitted together with the appropriate specifications (using

SI units). Tests should be carried out at an ambient temperature of

(20,±5)°C, unless other temperatures are indicated.

4.2 Visual examination

[7.2]

Before testing, nozzles should be examined visually with

respect to the following points:

4.3 Body strength [7.3]

4.3.1 The design load should be measured on ten

automatic nozzles by securely installing each nozzle at room temperature,

in a tensile/compression test machine and applying a force equivalent

to the application of the rated working pressure.

An indicator capable of reading deflection to an accuracy

of 0.01 mm should be used to measure any change in length of the nozzle

between its load bearing points. Movement of the nozzle shank thread

in the threaded bushing of the test machine should be avoided or taken

into account.

The hydraulic pressure and load is then released and the

heat responsive element is then removed by a suitable method. When

the nozzle is at room temperature, a second measurement is to be made

using the indicator.

An increasing mechanical load to the nozzle is then applied

at a rate not exceeding 500 N/minute, until the indicator reading

at the load bearing point initially measured returns to the initial

value achieved under hydrostatic load. The mechanical load necessary

to achieve this should be recorded as the service load. Calculate

the average service load.

4.3.2 The applied load is then progressively increased

at a rate not exceeding 500 N/minute on each of the five specimens

until twice the average service load has been applied. Maintain this

load for 15 ± 5 s.

The load is then removed and any permanent elongation as

defined in 3.6 is recorded.

4.4 Leak resistance and

hydrostatic strength tests (see

3.8

)

[7.4]

4.4.1 Twenty nozzles should be subjected to a

water pressure of twice their rated working pressure, but not less

than 34.5 bar. The pressure is increased from 0 bar to the test pressure,

maintained at twice rated working pressure for a period of 3 min and

then decreased to 0 bar. After the pressure has returned to 0 bar,

it is increased to the minimum operating pressure specified by the

manufacturer in not more than 5 s. This pressure is to be maintained

for 15 s and then increased to rated working pressure and maintained

for 15 s.

4.4.2 Following the test of 4.4.1, the twenty nozzles should

be subjected to an internal hydrostatic pressure of four times the

rated working pressure. The pressure is increased from 0 bar to four

times the rated working pressure and held there for a period of 1

minute. The nozzle under test should not rupture, operate or release

any of its operating parts during the pressure increase nor while

being maintained at four times the rated working pressure for 1 minute.

4.5 Functional test (see

3.5

) [7.5]

4.5.1 Nozzles having nominal release temperatures

less than 78°C, should be heated to activation in an oven. While

being heated, they should be subjected to each of the water pressures

specified in 4.5.3 applied

to their inlet. The temperature of the oven should be increased to

400 ± 20°C in 3 min measured in close proximity to the

nozzle. Nozzles having nominal release temperatures exceeding 78°C

should be heated using a suitable heat source. Heating should continue

until the nozzle has activated.

4.5.2 Eight nozzles should be tested in each normal

mounting position and at pressures equivalent to the minimum operating

pressure, the rated working pressure and the the average operating

pressure. The flowing pressure should be at least 75% of the initial

operating pressure.

4.5.3 If lodgement occurs in the release mechanism

at any operating pressure and mounting position, 24 more nozzles should

be tested in that mounting position and at that pressure. The total

number of nozzles for which lodgement occurs should not exceed 1 in

the 32 tested at that pressure and mounting position.

4.5.4 Lodgement is considered to have occurred

when one or more of the released parts lodge in the discharge assembly

in such a way a to cause the water distribution to be altered after

the period of time specified in 3.5.1.

4.5.5 In order to check the strength of the deflector/orifice

assembly, three nozzles should be submitted to the functional test

in each normal mounting position at 125 percent of the rated working

pressure. The water should be allowed to flow at 125 percent of the

rated working pressure for a period of 15 min.

4.6 Heat responsive element

operating characteristics

4.6.1 Operating temperature test (see

3.3

) [7.6]

Ten nozzles should be heated from room temperature to 20

to 22°C below their nominal release temperature. The rate of increase

of temperature should not exceed 20°C/min and the temperature

should be maintained for 10 min. The temeprature should then be increased

at a rate between 0.4°C/min to 0.7°C/min until the nozzle

operates.

The nominal operating temperature should be ascertained

with equipment having an accuracy of ±0.35% of the nominal

temperature rating or ±0.25°C, whichever is greater.

The test should be conducted in a water bath for nozzles

or separate glass bulbs having nominal release temperatures less than

or equal to 80°C. A suitable oil should be used for higher-rated

release elements. The liquid bath should be constructed in such a

way that the temperature deviation within the test zone does not exceed

0.5%, or 0.5°C, whichever is greater.

4.6.2 Dynamic heating test (see

3.4

)

4.6.2.1 Plunge test

Tests should be conducted to determine the standard and

worst case orientations as defined in 1.4 and 1.5. Ten additional

plunge test should be performed at both of the identified orientations.

The worst case orientation should be as defined in 3.14.1. The RTI is calculated as

described in 4.6.2.3 and 4.6.2.4 for

each orientation, respectively. The plunge tests are to be conducted

using a brass nozzle mount designed such that the mount or water temperature

rise does not exceed 2°C for the duration of an individual plunge

test up to a response time of 55 s. (The temperature should be measured

by a thermocouple heatsinked and embedded in the mount not more than

8 mm radially outward from the root diameter of the internal thread

or by a thermocouple located in the water at the centre of the nozzle

inlet.) If the response time is greater than 55 s, then the mount

or water temperature in degrees Celsius should not increase more than

0.036 times the response time in seconds for the duration of an individual

plunge test.

The nozzle under test should have 1 to 1.5 wraps of PTFE

sealant tape applied to the nozzle threads. It should be screwed into

a mount to a torque of 15 ± 3 Nm. Each nozzle is to be mounted

on a tunnel test section cover and maintained in a conditioning chamber

to allow the nozzle and cover to reach ambient temperature for a period

of not less than 30 min.

At least 25 ml of water, conditioned to ambient temperature,

should be introduced into the nozzle inlet prior to testing. A time

accurate to ±0.01 s with suitable measuring devices to sense

the time between when the nozzle is plunged into the tunnel and the

time it operates should be utilized to obtain the response time.

A tunnel should be utilized with air flow and temperature

conditionsfootnote at the test section (nozzle

location) selected from the appropriate range of conditions shown

in table 2. To minimize

radiation exchange between the sensing element and the boundaries

confining the flow, the test section of the apparatus should be designed

to limit radiation effects to within ±3% of calculated RTI

valuesfootnote.

Table 2 Plunge Oven Test

Conditions

|

|

Air Temperature ranges 4

|

Velocity ranges 5

|

| Normal

Temperature, ºC

|

Standard

Response, ºC

|

Special

response, ºC

|

Fast

Response, ºC

|

Standard

Response, m/s

|

Special

response, m/s

|

Fast Response

Nozzle, m/s

|

| 57 to

77

|

191 to

203

|

129 to

141

|

129 to

141

|

2.4 to

2.6

|

2.4 to

2.6

|

1.65 to

1.85

|

| 79 to

107

|

282 to

300

|

191 to

203

|

191 to

203

|

2.4 to

2.6

|

2.4 to

2.6

|

1.65 to

1.85

|

| 121 to

149

|

382 to

432

|

282 to

300

|

282 to

300

|

2.4 to

2.6

|

2.4 to

2.6

|

1.65 to

1.85

|

| 163 to

191

|

382 to

432

|

382 to

432

|

382 to

432

|

3.4 to

3.6

|

2.4 to

2.6

|

1.65 to

1.85

|

| 4.The selected air temperature

should be known and maintained constant within the test section

throughout the test section throughout the test to an accuracy of

+/- 1 ºC for the air temperature range of 129 to 141 ºC within the

test section and within +/- 2 ºC for all other air

temperatures.

|

| 5. The selected air velocity

should be known and maintained constant throughout the test to an

accuracy of +/-0.03 m/s fpr velocities of 1.65 to 1.85 and 2.4 to

2.6 m/s and +/-0.04 for velocities 3.4 to 3.6 m/s.

|

The range of permissible tunnel operating conditions is

shown in table 2. The selected

operating condition should be maintained for the duration of the test

with the tolerances as specified by footnotes 10 and 11 in table 2.

4.6.2.2 Determination of Conductivity Factor (C)

[7.6.2.2]

The conductivity factor (C) should be determined using the

prolonged plunge test (see 4.6.2.2.1) or the prolonged exposure ramp

test (see 4.6.2.2.2).

4.6.2.2.1 Prolonged Plunge Test [7.6.2.2.1]

The prolonged plunge test is an iterative process to determine

C and may require up to twenty nozzle samples. A new nozzle sample

must be used for each test in this section even if the sample does

not operate during the prolonged plunge test.

The nozzle under test should have 1 to 1.5 wraps of PTFE

sealant tape applied to the nozzle threads. It should be screwed into

a mount to a torque of 15 + 3 Nm. Each nozzle is to be mounted on

a tunnel test section cover and maintained in a conditioning chamber

to allow the nozzle and cover to reach ambient temperature for a period

of not less than 30 min. At least 25 ml of water, conditioned to ambient

temperature, should be introduced into the nozzle inlet prior to testing.

A timer accurate to ±0.01 s with suitable measuring

devices to sense the time between when the nozzle is plunged into

the tunnel and the time it operates should be utilized to obtain the

response time.

The mount temperature should be maintained at 20 ±

0.5°C for the duration of each test. The air velocity in the tunnel

test section at the nozzle location should be maintained with ±2%

of the selected velocity. Air temperature should be selected and maintained

during the test as specified in table

3.

Table 3 Plunge Oven

Test Conditions for Conductivity Determinations

| Nominal

nozzle temperature, ºC

|

Oven

temperature, ºC

|

Maximum

variation of air temperature during test, ºC

|

| 57

|

85 to 91

|

± 1.0

|

| 58 to 77

|

124 to 130

|

± 1.5

|

| 78 to 107

|

193 to 201

|

± 3.0

|

| 121 to 149

|

287 to 295

|

± 4.5

|

| 163 to 191

|

402 to 412

|

± 6.0

|

The range of permissible tunnel operating conditions is

shown in table 3. The selected

operating condition should be maintained for the duration of the test

with the tolerances as specified in table

3.

To determine C, the nozzle is immersed in the test stream

at various air velocities for a maximum of 15 minfootnote. Velocities are chosen such that actuation

is bracketed between two successive test velocities. That is, two

velocities must be established such that at the lower velocity (u1)

actuation does not occur in the 15 min test interval. At the next

higher velocity (uh), actuation must occur within the 15

min time limit. If the nozzle does not operate at the highest velocity,

select an air temperature from table

3 for the next temperature rating.

Test velocity selection should insure that:

The test value of C is the average of the values calculated

at the two velocities using the following equation:

where:

|

Δ T

g

|

= |

Actual gas (air) temperature minus the mount temperature (Tm)

in °C. |

|

Δ T

ea

|

= |

Mean liquid bath operating temperature minus the mount temperature

(Tm) in °C. |

|

u |

= |

Actual air velocity

in the test section in m/s. |

The nozzle C value is determined by repeating the bracketing

procedure three times and calculating the numerical average of the

three C values. This nozzle C value is used to calculate all standard

orientation RTI values for determining compliance with 3.14.1.

4.6.2.2.2 Prolonged Exposure Ramp Test [7.6.2.2.2]

The prolonged exposure ramp test for the determination of

the parameter C should be carried out in the test section of a wind

tunnel and with the requirements for the temperature in the nozzle

mount as described for the dynamic heating test. A preconditioning

of the nozzle is not necessary.

Ten samples should be tested of each nozzle type, all nozzles

positioned in standard orientation. The nozzle should be plunged into

an air stream of a constant velocity of 1 m/s ± 10% and an

air temperature at the nominal temperature of the nozzle at the beginning

of the test.

The air temperature should then be increased at a rate of

1 ± 0.25°C/min until the nozzle operates. The air temperature,

velocity and mount temperature should be controlled from the initiation

of the rate of rise and should be measured and recorded at nozzle

operation. The C value is determined using the same equation as in

4.6.2.2.1 as the average of the ten test values.

4.6.2.3 RTI Value Calculation [7.6.2.3]

The equation used to determine the RTI value is a follows:

where:

|

t

r

|

= |

response

time of nozzles in seconds |

|

u

|

= |

Actual air velocity

in the test section of the tunnel in m/s from table 2

|

|

ΔT

ea

|

= |

Mean

liquid bath operating temperature of the nozzle minus the ambient

temperature in °C |

|

ΔT

g

|

= |

Actual

air temperature in the test section minus the ambient temperature

in °C |

|

C |

= |

Conductivity factor as determined

in 4.6.2.2 |

4.6.2.4 Determination of Worst Case Orientation

RTI

The equation used to determine the RTI for the worst case

orientation is as follows:

where:

|

t

r-wc

|

= |

Response

time of the nozzles in seconds for the worst case orientation |

All variables are known at this time per the equation in

paragraph 4.6.2.3 except RTIwc (Response Time Index for

the worst case orientation) which can be solved iteratively per the

above equation.

In the case of fast response nozzles, if a solution for

the worse case orientation RTI is unattainable, plunge testing in

the worst case orientation should be repeated using the plunge test

conditions under Special Response shown in table 2.

4.7 Heat Exposure Test

[7.7]

4.7.1 Glass Bulb Nozzles (see

3.9.1

)

Glass bulb nozzles having nominal release temperatures less

than or equal to 80°C should be heated in a water bath from a

temperature of (20 ± 5)°C to (20 ± 2)°C below

their nominal release temperature. The rate of increase of temperature

should not exceed 20°C/min. High temperature oil, such as silicone

oil should be used for higher temperature rated release elements.

This temperature should then be increased at a rate of 1°C/min

to the temperature at which the gas bubble dissolves, or to a temperature

5°C lower than the nominal operating temperature, whichever is

lower. Remove the nozzle from the liquid bath and allow it to cool

in air until the gas bubble has formed again. during the cooling period,

the pointed end of the glass bulb (seal end) should be pointing downwards.

This test should be performed four times on each of four nozzles.

4.7.2 All Uncoated Nozzles (see

3.9.2

) [7.7.2]

Twelve uncoated nozzles should be exposed for a period of

90 days to a high ambient temperature that is 11°C below the nominal

rating or at the temperature shown in table 4, whichever is lower, but not less than 49°C. If

the service load is dependent on the service pressure, nozzles should

be tested under the rated working pressure. After exposure, four of

the nozzles should be subjected to the tests specified in 4.4.1, four nozzles to the test

of 4.5.1. two at the minimum

operating pressure and two at the rated working pressure, and four

nozzles to the requirements 3.3.

If a nozzle fails the applicable requirements of a test, eight additional

nozzles should be tested as described above and subjected to the test

in which the failure was recorded. All eight nozzles should comply

with the test requirements.

Table 4 Test Temperatures

for Coated and Uncoated Nozzles

| Values in degrees Celsius

|

| Nominal release

temperature

|

Uncoated nozzle

test temperature

|

Coated nozzle

test temperature

|

| 57–60

|

49

|

49

|

| 61–77

|

52

|

49

|

| 78–107

|

79

|

66

|

| 108–149

|

121

|

107

|

| 150 to 191

|

149

|

149

|

| 192–246

|

191

|

191

|

| 247–302

|

246

|

246

|

| 303–343

|

302

|

302

|

4.7.3 Coated Nozzles (see

3.9.3

) [7.7.3]

In addition to the exposure test of 4.7.2 in an uncoated version, twelve

coated nozzles should be exposed to the test of 4.7.2 using the temperatures

shown in table 4 for coated

nozzles.

The test should be conducted for 90 days. During this period,

the sample should be removed from the oven at intervals of approximately

7 days and allowed to cool for 2 h to 4 h. During this cooling period,

the sample should be examined. After exposure, four of the nozzles

should be subjected to the tests specified in 4.4.1, four nozzles to the test

of 4.5.1; two at the minimum

operating pressure and two at the rated working pressure, and four

nozzles to the requirements of 3.3.

4.8 Thermal Shock Test

for Glass Bulb Nozzles (see

3.10

)

[7.8]

Before starting the test, condition at least 24 nozzles

at room temperature of 20 to 25°C for at least 30 min.

The nozzles should be immersed in a bath of liquid, the

temperature of which should be 10 ± 2°C below the nominal

release temperature of the nozzles. After 5 min, the nozzles are to

be remove from the bath and immersed immediately in another bath of

liquid, with the bulb seal downwards, at a temperature of 10 ±

1°C. Then test the nozzles in accordance with 4.5.1.

4.9 Strength Test for

Release Elements [7.9]

4.9.1 Glass Bulbs (see

3.7.1

) [7.9.1]

At least 15 sample bulbs in the lowest temperature rating

of each bulb type should be positioned individually in a test fixture

using the sprinkler seating parts. Each bulb should then be subjected

to a uniformly increasing force at a rate not exceeding 250 N/s in

the test machine until the bulb fails.

Each test should be conducted with the bulb mounted in new

seating parts. The mounting device may be reinforced externally to

prevent its collapse, but in a manner which does not interfere with

bulb failure.

Record the failure load for each bulb. Calculate the lower

tolerance limit (TL1) for bulb strength. Using the values of service

load recorded in 4.3.1, calculate

the upper tolerance limit (TL2) for the bulb design load. Verify compliance

with 3.7.1.

4.9.2 Fusible Elements (see

3.7.2

)

4.10 Water Flow Test

(see

3.4.1

) [7.10]

The nozzle and a pressure gauge should be mounted on a supply

pipe. The water flow should be measured at pressures ranging from

the minimum operating pressure to the rated working pressure at intervals

of approximately 10% of the service pressure range on two sample nozzles.

In one series of tests, the pressure should be increased from zero

to each value and, in the next series, the pressure shall be decreased

from the rated pressure to each value. The flow constant, K, should

be averaged from each series of readings, i.e., increasing pressure

and decreasing pressure. During the test, pressures should be corrected

for differences in height between the gauge and the outlet orifice

of the nozzle.

4.11 Water Distribution

and Droplet Size Tests

4.11.1 Water Distribution (see

3.4.2

)

The tests should be conducted in a test chamber of minimum

dimensions 7 m x 7 m or 300% of the maximum design area being tested,

whichever is greater. For standard automatic nozzles, install a single

open nozzle and then four open nozzles of the same type arranged in

a square, at maximum spacings specified by the manufacturer, on piping

prepared for this purpose. For pilot type nozzles, install a single

nozzle and then the maximum number of slave nozzles at their maximum

spacings, specified in the Manufacturer Design and Installation Instructions.

The distance between the ceiling and the distribution plate

should be 50 mm for upright nozzles and 275 mm for pendent nozzles.

For nozzles without distribution plates, the distances shall be measured

from the ceiling to the highest nozzle outlet.

Recessed, flush and concealed type nozzles should be mounted

in a false ceiling of dimensions not less than 6 m x 6 m and arranged

symmetrically in the test chamber. The nozzles should be fitted directly

into the horizontal pipework by means of “T" or elbow fittings.

The water discharge distribution in the protected area below

a single nozzle and between the multiple nozzles should be collected

and measured by means of square measuring containers nominally 300

mm on a side. The distance between the nozzles and the upper edge

of the measuring containers should be the maximum specified by the

manufacturer. The measuring containers should be positioned centrally,

beneath the single nozzle and beneath the multiple nozzles.

The nozzles should be discharged both at the minimum operating

and rated working pressures specified by the manufacturer and the

minimum and maximum installation heights specified by the manufacturer.

The water should be collected for at least 10 min to assist

in characterizing nozzle performance.

4.11.2 Water Droplet Size (see

3.4.3

)

The mean water droplet diameters. velocities, droplet size

distribution, number density and volume flux should be determined

at both the minimum and maximum flow rates specified by the manufacturer.

Once the data is gathered, the method of the “Standard Practice

for Determining Data Criteria and Processing for Liquid Drop Size

Analysis" (ASTM E799-92) will be used to determine the appropriate

sample size, class size widths, characteristic drop sizes and measured

dispersion of the drop size distribution. This data should be taken

at various points within the spray distribution as described in 3.4.3.

4.12 Corrosion Test

[7.12]

4.12.1 Stress Corrosion

Test for Brass Nozzle Parts (see

3.11.1

)

Five nozzles should be subjected to the following aqueous

ammonia test. The inlet of each nozzle should be sealed with a nonreactive

cap, e.g., plastic.

The samples are degreased and exposed for 10 days to a moist

ammonia-air mixture in a glass container of volume 0.02 ± 0.01

m3.

An aqueous ammonia solution, having a density of 0.94 g/cm3, should be maintained in the bottom of the container, approximately

40 mm below the bottom of the samples. A volume of aqueous ammonia

solution corresponding to 0.01 ml per cubic centimetre of the volume

of the container will give approximately the following atmospheric

concentrations: 35% ammonia, 5% water vapour, and 60% air. The inlet

of each sample should be sealed with a nonreactive cap, e.g. plastic.

The moist ammonia-air mixture should be maintained as closely

as possible at atmospheric pressure, with the temperature maintained

at 34 ± 2°C. Provision should be made for venting the chamber

via a capillary tube to avoid the build-up of pressure. Specimens

should be shielded from condensate drippage.

After exposure, rinse and dry the nozzles, and conduct a

detailed examination. If a crack, delamination or failure of any operating

part is observed, the nozzle(s) should be subjected to a leak resistance

test at the rated pressure for 1 min and to the functional test at

the minimum flowing pressure (see 3.1.5).

Nozzles showing cracking, delamination or failure of any

non-operating part should not show evidence of separation of permanently

attached parts when subjected to flowing water at the rated working

pressure for 30 min.

4.12.2 Stress-Corrosion

Cracking of Stainless Steel Nozzle Parts (see

3.11.1

)

4.12.2.1 Five samples are to be degreased prior

to being exposed to the magnesium chloride solution.

4.12.2.2 Parts used in nozzles are to be place

in a 500-millilitre flask that is fitted with a thermometer and a

wet condenser approximately 760 mm long. the flask is to be filled

approximately one-half full with 42% by weight magnesium chloride

solution, placed on a thermostatically-controlled electrically heated

mantel, and maintained at a boiling temperature of 150 ± 1°C.

The parts are to be unassembled, that is, not contained in a nozzle

assembly. The exposure is to last for 500 hours.

4.12.2.3 After exposure period, the test samples

are to be removed from the boiling magnesium chloride solution and

rinsed in deionized water.

4.12.2.4 The test samples are then to be examined

using a microscope having a magnification of 25X for any cracking,

delamination, or other degradation as a result of the test exposure.

Test samples exhibiting degradation are to be tested as described

in 4.12.5.5 or 4.12.5.6,

as applicable. test samples not exhibiting degradation are considered

acceptable without further test.

4.12.2.5 Operating parts exhibiting degradation

are to be further tested as follows. Five new sets of parts are to

be assembled in nozzle frames made of materials that do not alter

the corrosive effects of the magnesium chloride solution on the stainless

steel parts. These test samples are to be degreased and subjected

to the magnesium chloride solution exposure specified in paragraph 4.12.5.2. following the exposure,

the test samples should withstand, without leakage, a hydrostatic

test pressure equal to the rated working pressure for 1 minute and

then be subjected to the functional test at the minimum operating

pressure in accordance with 4.5.1.

4.12.2.6 Non-operating parts exhibiting degradation

are to be further tested as follows. Five new sets of parts are to

be assembled in nozzle frames made of materials that do not alter

the corrosive effects of the magnesium chloride solution on the stainless

steel parts. These test samples are to be degreased and subjected

to the magnesium chloride solution exposure specified in paragraph 4.12.5.1. Following the exposure,

the test samples should withstand a flowing pressure equal to the

rated working pressure for 30 minutes without separation of permanently

attached parts.

4.12.3 Sulphur Dioxide

Corrosion Test (see

3.11.2

and

3.14.2

)

Ten nozzles should be subjected to the following sulphur

dioxide corrosion test. The inlet of each sample should be sealed

with a nonreactive cap, e.g. plastic.

The test equipment should consist of a 5 litre vessel (instead

of a 5 litre vessel, other volumes up to 15 litre may be used in which

case the quantities of chemicals given below shall be increased in

proportion) made of heat-resistant glass, with a corrosion-resistant

lid of such a shape as to prevent condensate dripping on the nozzles.

The vessel should be electrically heated through the base, and provided

with a cooling coil around the side walls. A temperature sensor placed

centrally 160 mm ± 20 mm above the bottom of the vessel should

regulate the heating so that the temperature inside the glass vessel

is 45°C ± 3°C. During the test, water should flow through

the cooling coil at a sufficient rate to keep the temperature of the

discharge water below 30°C. This combination of heating and cooling

should encourage condensation on the surfaces of the nozzles. The

sample nozzles should be shielded from condensate drippage.

The nozzles to be tested should be suspended in their normal

mounting position under the lid inside the vessel and subjected to

a corrosive sulphur dioxide atmosphere for 8 days. The corrosive atmosphere

should be obtained by introducing a solution made up by dissolving

20 g of sodium thiosulphate (Na2S2O3H2O) crystals in 500 ml of water.

For at least six days of the 8-day exposure period, 20 ml

of dilute sulphuric acid consisting of 156 ml of normal H2SO4 (0.5 mol/liter) diluted with 844 ml of water should be added

at a constant rate. After 8 days, the nozzles should be removed form

the container and allowed to dry for 4 to 7 days at a temperature

not exceeding 35°C with a relative humidity not greater than 70%.

After the drying period. five nozzles should be subjected

to a functional test at the minimum operating pressure in accordance

with 4.5.1 and five nozzles

should be subjected to the dynamic heating test in accordance with 3.14.2.

4.12.4 Salt Spray

Corrosion Test (see

3.11.3

and

3.14.2

) [7.12.3]

4.12.4.1 Nozzles Intended for Normal Atmospheres

Ten nozzles should be exposed to a salt spray within a fog

chamber. The inlet of each sample should be sealed with a nonreactive

cap, e.g. plastic.

During the corrosive exposure, the inlet thread orifice

is to be sealed by a plastic cap after the nozzles have been filled

with deionized water. The salt solution should be a 20% by mass sodium

chloride solution in distilled water. The pH should be between 6.5

and 3.2 and the density between 1.126 g/ml and 1.157 g/ml when atomized

at 35°C. Suitable means of controlling the atmosphere in the chamber

should be provided. The specimens should be supported in their normal

operating position and exposed to the salt spray (fog) in a chamber

having a volume of at least 0.43 m3 in which the exposure

zone shall be maintained at a temperature of 35 ± 2°C.

The temperature should be recorded at least once per day, at least

7 hours apart (except weekends and holidays when the chamber normally

would not be opened). Salt solution should be supplied from a recirculating

reservoir through air-aspirating nozzles, at a pressure between 0.7

bar (0.07 MPa) and 1.7 bar (0.17 MPa). Salt solution runoff from exposed

samples should be collected and should not return to the reservoir

for recirculation. The sample nozzles should be shielded from condensate

drippage.

Fog should be collected from at least two points in the

exposure zone to determine the rate of application and salt concentration.

The fog should be such that for each 80 cm2 of collection

area, 1 ml to 2 ml of solution should be collected per hour over a

16 hours period and the salt concentration shall be 20 ± 1%

by mass.

The nozzles should withstand exposure to the salt for a

period of 10 days. After this period, the nozzles should be removed

from the fog chamber and allowed to dry for 4 to 7 days at a temperature

of 20 to 25°C in an atmosphere having a relative humidity not

greater than 70%. Following the drying period, five nozzles should

be submitted to the functional test at the minimum operating pressure

in accordance with 4.5.1 and

five nozzles should be subjected to the dynamic heating test in accordance

with 3.14.2.

4.12.4.2 Nozzles Intended for Corrosive Atmospheres

[7.12.3.2]

Five nozzles should be subjected to the tests specified

in 4.12.3.1 except that

the duration of the salt spray exposure shall be extended from 10

days to 30 days.

4.12.5 Moist Air Exposure

Test (see

3.11.4

and

3.14.2

) [7.12.4]

Ten nozzles should be exposed to a high temperature-humidity

atmosphere consisting of a relative humidity of 98% ± 2% and

a temperature of 95°C ± 4°C. The nozzles are to be

installed on a pipe manifold containing deionized water. The entire

manifold is to be placed in the high temperature humidity enclosure

for 90 days. After this period, the nozzles should be removed from

the temperature-humidity enclosure and allowed to dry for 4-7 days

at a temperature of 25 ± 5°C in an atmosphere having a

relative humidity of not greater than 70%. Following the drying period,

five nozzles should be functionally tested at the minimum operating

pressure in accordance with 4.5.1 and

five nozzles should be subjected to the dynamic heating test in accordance

with 3.14.2.

At the manufacturer's option, additional samples may be

furnished for this test to provide early evidence of failure. The

additional samples may be removed from the test chamber at 30-day

intervals for testing.

4.13 Nozzle Coating

Tests [7.13]

4.13.1 Evaporation Test (see

3.12.1

) [7.13.1]

A 50 cm3 sample of wax or bitumen should be placed

in a metal or glass cylindrical container, having a flat bottom, an

internal diameter of 55 mm and an internal height of 35 mm. The container,

without lid, should be placed in an automatically controlled electric,

constant ambient temperature oven with air circulation. The temperature

in the oven should be controlled at 16°C below the nominal release

temperature of the nozzle, but at not less than 50°C. The sample

should be weighed before and after 90 days exposure to determine any

loss of volatile matter; the sample should meet the requirements of

3.12.1.

4.13.2 Low-Temperature Test (see

3.12.2

) [7.13.2]

Five nozzles, coated by normal production methods, whether

with wax, bitumen or a metallic coating, should be subjected to a

temperature of -10°C for a period of 24 hours. On removal from

the low-temperature cabinet, the nozzles should be exposed to normal

ambient temperature for a least 30 min before examination of the coating

to the requirements of 3.12.2.

4.14 Heat-Resistance

Test (see

3.15

) [7.14]

One nozzle body should be heated in an oven at 800°C

for a period of 15 min, with the nozzle in its normal installed position.

The nozzle body should then be removed, holding it by the threaded

inlet, and should be promptly immersed in a water bath at a temperature

of approximately 15°C. It should meet the requirements of 3.15.

4.15 Water-Hammer Test

(see

3.13

) [7.15]

Five nozzles should be connected, in their normal operating

position, to the test equipment. After purging the air from the nozzles

and the test equipment, 3,000 cycles of pressure varying from 4 ±

2 bar ((0.4 ± 0.2)MPa) to twice the rated working pressure

should be generated. The pressure should be raised from 4 bar to twice

the rated working pressure at a rate of 60 ± 10 bar/s. At least

30 cycles of pressure per minute should be generated. The pressure

should be measured with an electrical pressure transducer.

Visually examine each nozzle for leakage during the test.

After the test, each nozzle should meet the leakage resistance requirement

of 3.8.1 and the functional

requirements of 3.5.1 at the

minimum operating pressure.

4.16 Vibration Test

(see

3.16

) [7.16]

4.16.1 Five nozzles should be fixed vertically

to a vibration table. They should be subjected at room temperature

to sinusoidal vibrations. The direction of vibration should be along

the axis of the connecting thread.

4.16.2 The nozzles should be vibrated continuously

from 5 Hz to 40 Hz at a maximum rate of 5 min/octave and an amplitude

of 1 mm (1/2 peak-to-peak value). If one or more resonant points are

detected, the nozzles after coming to 40 Hz, should be vibrated at

each of these resonant frequencies for 120 hours/number of resonances.

If no resonances are detected, the vibration from 5 Hz to 40 Hz should

be continued for 120 hours.

4.16.3 The nozzle should then be subjected to

the leakage test in accordance with 3.8.1 and the functional test in accordance with 3.5.1 at the minimum operating pressure.

4.17 Impact Test (see

3.17

) [7.17]

Five nozzles should be tested by dropping a mass onto the

nozzle along the axial centreline of waterway. The kinetic energy

of the dropped mass at the point of impact should be equivalent to

a mass equal to that of the test nozzle dropped from a height 1 m.

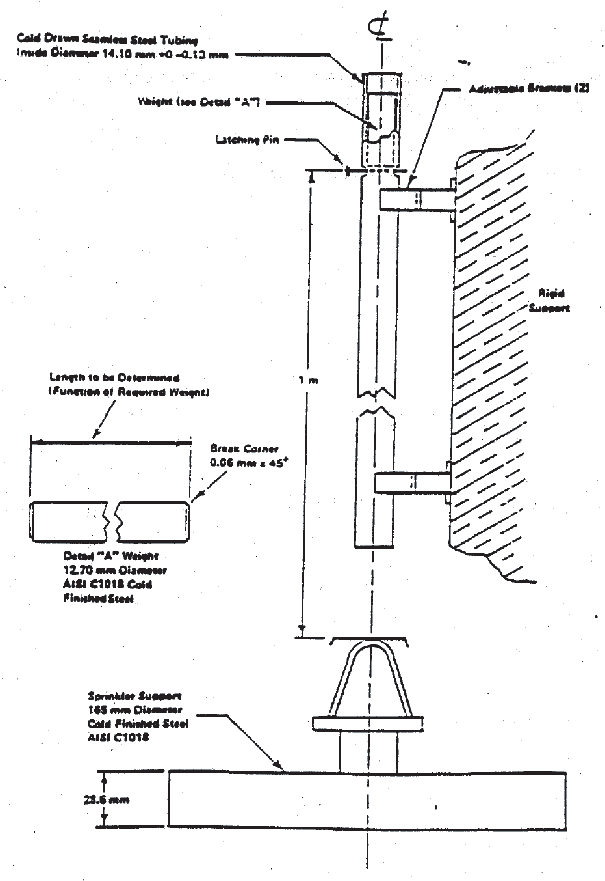

See Figure 2. The mass is

to be prevented from impacting more than once upon each sample.

Figure 2 Impact Test Apparatus

Following the test a visual examination of each nozzle shall

show no signs of fracture, deformation, or other deficiency. If none

is detected, the nozzles should be subjected top the leak resistance

test, described in 4.4.1.

Following the leakage test, each sample should meet the functional

test requirement of 4.5.1 at

a pressure equal to the minimum flowing pressure.

4.18 Lateral Discharge

Test (see

3.18

) [7.19]

Water is to be discharged from a spray nozzle at the minimum

operating and rated working pressure. A second automatic nozzle located

at the minimum distance specified by the manufacturer is mounted on

a pipe parallel to the pipe discharging water.

The nozzle orifices or distribution plates (if used), are

to be placed 550 mm, 356 mm and 152 mm below a flat smooth ceiling

for three separate tests, respectively at each test pressure. The

top of a square pan measuring 305 mm square and 102 mm deep is to

be positioned 152 mm below the heat responsive element for each test.

The pan is filled with 0.47 litres of heptane. After ignition the

automatic nozzle is to operate before the heptane is consumed.

4.19 30 Day Leakage

Test (see

3.19

) [7.20]

Five nozzles are to be installed on a water filled test

line maintained under a constant pressure of twice the rated working

pressure for 30 days at an ambient temperature of (20 ± 5°C).

The nozzles should be inspected visually at least weekly

for leakage. Following completion of this 30 day test, all samples

should meet the leak resistance requirements specified in 3.2.4 and should exhibit no evidence

of distortion or other mechanical damage.

4.20 Vacuum Test (see

3.20

) [7.21]

Three nozzles should be subjected to a vacuum of 460 mm

of mercury applied to a nozzle inlet for 1 min at an ambient temperature

of (20 ± 5°C). Following this test, each sample should

be examined to verify that no distortion or mechanical damage has

occurred and then should meet the leak resistance requirements specified

in 4.4.1.

4.21 Clogging Test (see

3.22

) [7.28]

4.21.1 The water flow rate of an open water mist

nozzle with its strainer or filter should be measured at its rated

working pressure. The nozzle and strainer or filter should then be

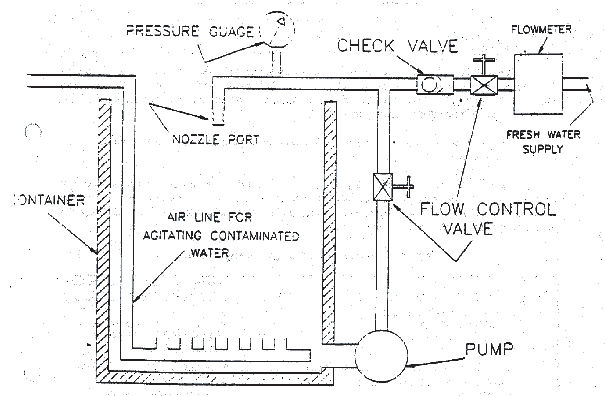

installed in test apparatus described in Figure 3 and subjected to 30 minutes

of continuous flow at rated working pressure using contaminated water

which has been prepared in accordance with 4.21.3.

Figure 3 Clogging test apparatus

4.21.2 Immediately following the 30 minutes of

continuous flow with contaminated water, the flow rate of the nozzle

and strainer or filter should be measured at rated working pressure.

No removal, cleaning or flushing of the nozzle, filter or strainer

is permitted during the test.

4.21.3 The water used during the 30 minutes of

continuous flow at rated working pressure specified in 4.21.1 should

consist of 60 litres of tap water into which has been mixed 1.58 kilograms

of contaminants which sieve as described in table 6. The solution should be

continuously agitated during the test.

Table 6 Contaminant for the

Contaminated Water Cycling Test

| SIEVE DESIGNATION

*

|

NOMINAL SIEVE OPENING,

MM

|

GRAMS OF CONTAMINANT (± 5

PERCENT)

|

| PIPE

SCALE

|

TOP SOIL

|

SAND

|

| No.

25

|

0.706

|

—

|

456

|

200

|

| No.

50

|

0.297

|

82

|

82

|

327

|

| No.

100

|

0.150

|

84

|

6

|

89

|

| No.

200

|

0.074

|

81

|

—

|

21

|

| No.

325

|

0.043

|

153

|

—

|

3

|

|

|

TOTAL

|

400

|

544

|

640

|

|