1 INTRODUCTION

The purpose of these Guidelines is to assist recognized organizations in the

validation of Electric Power Tables (EPT) for the calculation of the Energy Efficiency

Design Index (EEDI) for ships. As such, these Guidelines support the implementation of

the EEDI Calculation Guidelines and the Guidelines on survey and certification of the

Energy Efficiency Design Index (EEDI). These Guidelines will also assist

shipowners, shipbuilders, ship designers and manufacturers in relation to aspects of the

development of more energy efficient ships and also in understanding the procedures for

the EPT-EEDI validation.

2 OBJECTIVES

These Guidelines provide a framework for the uniform application of the

EPT-EEDI validation process for ships for which required auxiliary engine power is

calculated under paragraph 2.2.5.7 of the EEDI Calculation Guidelines.

3 DEFINITIONS

3.1 Applicant means an organization, primarily a shipbuilder or a ship

designer, which requests the EPT-EEDI validation in accordance with these Guidelines.

3.2 Validator means a recognized organization which conducts the

EPT-EEDI validation in accordance with these Guidelines.

3.3 Validation for the purpose of these Guidelines means review of

submitted documents and survey during construction and sea trials.

3.4 Standard EPT-EEDI-Form refers to the layout given in appendix 3,

containing the EPT-EEDI results that will be the subject of validation. Other supporting

documents submitted for this purpose will be used as reference only and will not be

subject to validation.

3.5 PAE herein is defined as per the definition in

paragraph 2.2.5.6 of the EEDI Calculation Guidelines.

3.6 Ship service and engine-room loads refer to all the load groups

which are needed for the hull, deck, navigation and safety services, propulsion and

auxiliary engine services, engine-room ventilation and auxiliaries and ship's general

services.

3.7 Diversity factor is the ratio of the "total installed load power"

and the "actual load power" for continuous loads and intermittent loads. This factor is

equivalent to the product of service factors for load, duty and time.

4 APPLICATION

4.1 These Guidelines are applicable to ships as stipulated in paragraph

2.2.5.7 of the EEDI Calculation Guidelines.

4.2 These Guidelines should be applied to new ships for which an application

for an EPT-EEDI validation has been submitted to a validator.

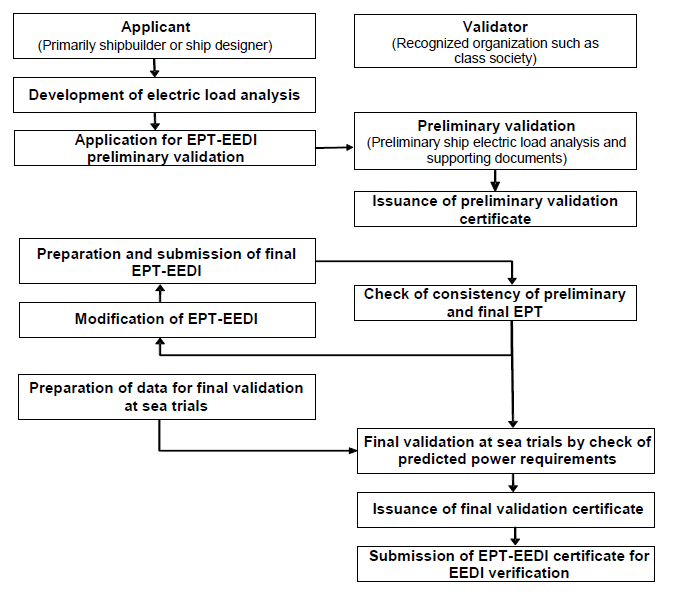

4.3 The steps of the validation process include:

5 SUPPORTING DOCUMENTS

5.1 The applicant should provide as a minimum the ship electric balance load

analysis.

5.2 Such information may contain shipbuilders' confidential information.

Therefore, after the validation, the validator should return all or part of such

information to the applicant at the applicant's request.

5.3 A special EEDI condition during sea trials may be needed and defined for

each ship and included in the sea trial schedule. For this condition, a special column

should be inserted into the EPT.

6 PROCEDURES FOR VALIDATION

6.1 General

PAE should be calculated in accordance with the EPT-EEDI

Calculation Guidelines. EPT-EEDI validation should be conducted in two stages:

preliminary validation at the design stage and final validation during sea trials. The

validation process is presented in figure 6.1.

Figure 6.1: Basic flow of EPT-EEDI validation process

6.2 Preliminary validation at the design stage

6.2.1 For the preliminary validation at the design stage, the applicant should submit to

a validator an application for the validation of EPT-EEDI, inclusive of the EPT-EEDI

Form, and all the relevant and necessary information for the validation as supporting

documents.

6.2.2 The applicant should supply as a minimum the supporting data and information, as

specified in appendix A (to be developed).

6.2.3 The validator may request from the applicant additional information to

that contained in these Guidelines, as necessary, to enable the validator to examine the

calculation process of the EPT-EEDI. The estimation of the ship EPT-EEDI at the design

stage depends on each applicant's experience, and it may not be practicable to fully

examine the technical aspects and details of each machinery component. Therefore, the

preliminary validation should focus on the calculation process of the EPT-EEDI that

should follow best marine practices.

- Note: A possible way forward for more robust validation is

to establish a standard methodology of deriving the ship EPT by setting standard

formats as agreed and used by industry.

6.3 Final validation

6.3.1 The final validation process should as a minimum include a check of the ship

electric load analysis to ensure that all electric consumers are listed. Their specific

data and the calculations in the power table itself are correct and are supported by sea

trial results. If necessary, additional information has to be requested.

6.3.2 For the final validation, the applicant should revise the EPT-EEDI Form and

supporting documents as necessary, by taking into account the characteristics of the

machinery and other electrical loads actually installed on board the ship. The EEDI

condition at sea trials should be defined and the expected power requirements in these

conditions documented in the EPT. Any changes within the EPT from design stage to

construction stage should be highlighted by the shipyard.

6.3.3 The preparation for the final validation includes a desk top check

comprising:

-

.1 consistency of preliminary and final EPT;

-

.2 changes of service factors (compared to the preliminary

validation);

-

.3 all electric consumers are listed;

-

.4 their specific data and the calculations in the power table

itself are correct; and

-

.5 in case of doubt, component specification data is checked in

addition.

6.3.4 A survey prior to sea trials is performed to ensure that machinery characteristics

and data as well as other electric loads comply with those recorded in the supporting

documents. This survey does not cover the complete installation but selects randomly a

number of samples.

6.3.5 For the purpose of sea trial validation, the surveyor will check the data of

selected systems and/or components given in the special column added to the EPT for this

purpose or the predicted overall value of electric load by means of practicable

measurements with the installed measurement devices.

7 ISSUANCE OF THE EPT-EEDI STATEMENT OF VALIDATION

7.1 The validator should stamp the EPT-EEDI Form as "Noted" having validated

the EPT-EEDI in the preliminary validation stage, in accordance with these Guidelines.

7.2 The validator should stamp the EPT-EEDI Form as "Endorsed" having

validated the final EPT-EEDI in the final validation stage in accordance with these

Guidelines.