1.5.1 Scope

This procedure details the laboratory determination of transportable

moisture limit (TML) for coals up to a nominal top size of 50 mm. The procedure is based

on a modification of the Proctor/Fagerberg test described in section 1.3 of this

appendix.

Key modifications to the original test procedure contained in 1.3 of this

appendix are:

-

.1 Sample preparation to facilitate the testing of 0 x 50 mm coal

through reconstitution to -25 mm;

-

.2 Use of a 150 mm diameter compaction cylinder; and

-

.3 Sample compaction using a hammer equivalent to the

Proctor/Fagerberg "D" energy hammer.

The transportable moisture limit is the moisture content corresponding to

the intersection of the 70% degree saturation curve and the test sample compaction

curve.

In the case of coals where moisture freely drains from the sample such that

the test sample compaction curve does not extend to or beyond 70% saturation, the test

is taken to indicate a cargo where water passes through the spaces between particles and

there is no increase in pore water pressure. Therefore, the cargo is not liable to

liquefy. (See 7.2.2 of this Code).

The procedure commences with a drum of coal containing a sample of not less

than 170 kg delivered to the testing laboratory and terminates with the laboratory

reporting the test result for the coal. Details of the sample collection process are

excluded from this procedure. However, it is important that the sample accurately

represents the size distribution of the cargo and reference should be made to the

normative reference list below.

1.5.2 Normative references

The following documents are referenced in this procedure. For dated

references, only the cited edition applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

-

– AS 1289.3.5.1:2006, Methods of testing soils for engineering

purposes. Method 3.5.1: Soil classification tests – Determination of the soil

particle density of a soil – Standard method;

-

– ISO 589:2008, Hard Coal – Determination of total moisture;

-

– ISO 3310-2:2013, Test requirements and testing – Part 2: Test

sieves of perforated metal plate; and

-

– ISO 13909-4:2001, Hard coal and coke – Mechanical sampling –

Part 4 – Coal – Preparation of test samples.

1.5.3 Definitions

1.5.3.1 Transportable moisture limit (TML)

The transportable moisture limit (TML) of a cargo which may liquefy means

the maximum moisture content of the cargo which is considered safe for carriage in a

ship not complying with the requirements in 7.3.2 of this Code.

1.5.3.2 Test outcomes

The transportable moisture limit determined by this procedure is the

moisture content corresponding to the intersection of the 70% degree saturation curve

and the test sample compaction curve. This is also referred to as the PFD70 value

(Proctor/Fagerberg – D energy hammer – 70% saturation).

Where moisture freely drains from the sample or the cylindrical mould at

moisture content such that the test sample compaction curve does not extend to or beyond

70% saturation (as described in 1.5.5.3.4), the test is taken to indicate a cargo where

water passes through the spaces between particles and there is no increase in pore water

pressure. Therefore, the cargo is not liable to liquefy. (See 7.2.2 of this Code).

1.5.3.3 Optimum moisture content (OMC)

The optimum moisture content is the moisture content corresponding to the

maximum compaction (maximum dry density) under the specified compaction condition.

1.5.3.4 Gross water content or total moisture (W1)

The moisture content of a sample is calculated as the mass of water divided

by the total mass of solids plus water and is referred to as either the gross water

content or the total moisture content. Gross water content is to be determined using the

method for determining total moisture defined in the standard ISO 589:2008.

1.5.4 Determination of the TML of blends of two or more coals

In circumstances where a shipper intends to load a cargo consisting of a

blend of two or more coals, the shipper may:

1.5.5 Modified Proctor/Fagerberg test procedure for coal

1.5.5.1 Apparatus

1.5.5.1.1 Work area

The work area should be located where the samples are protected from

excessive temperatures, air currents and humidity variations. All samples should be

stored in suitable sample containers, including plastic sample bags, and the containers

should be sealed.

1.5.5.1.2 Standard sieves

Square aperture laboratory sieves of 16 mm and 25 mm aperture as nominated

in ISO 3310-2:2013 are required for reconstitution of the sample at 25 mm top size. A

2.36 mm sieve is required for generation of + 2.36 mm and – 2.36 mm fractions for

particle density determination. Optionally a 2 mm sieve may be used for this purpose.

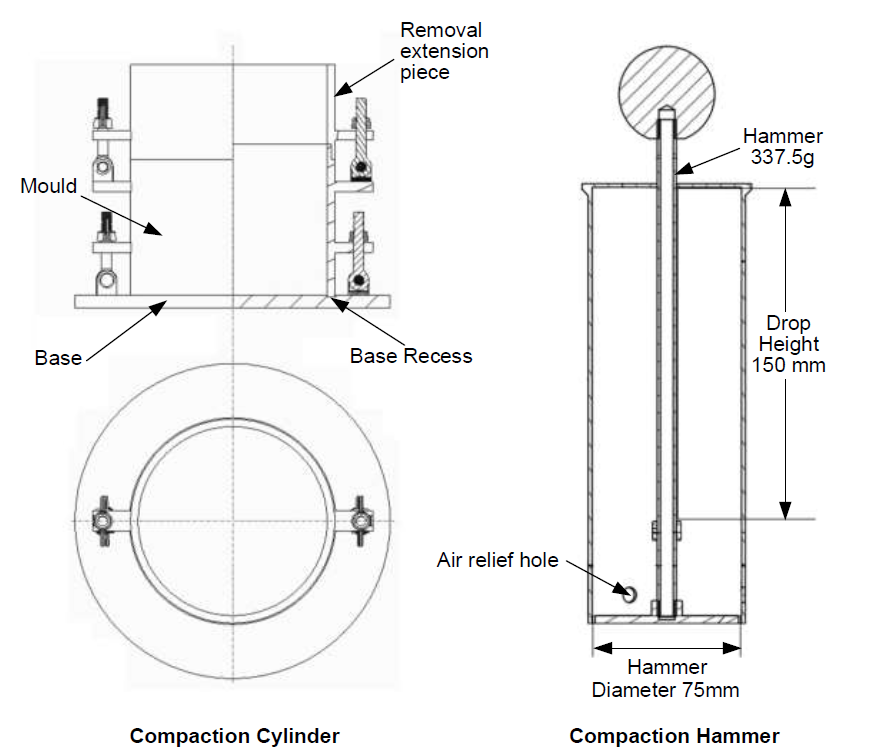

1.5.5.1.3 Proctor/Fagerberg apparatus

The Proctor/Fagerberg apparatus consists of a cylindrical stainless steel

mould having 150 mm diameter and 120 mm height with a removable extension piece (the

compaction cylinder) and a compaction tool guided by a pipe at its lower end (the

compaction hammer), which are shown in figure 1.5.5.1.3.1. A schematic diagram of the

Proctor/Fagerberg apparatus is shown in figure 1.5.5.1.3.2 with dimensions and

tolerances indicated in table 1.5.6.2.

Figure 1.5.5.1.3.1 – Example of Proctor/Fagerberg test apparatus, hammer and

hammer guide

Figure 1.5.5.1.3.2 – Schematic of a Proctor/Fagerberg apparatus

1.5.5.1.4 Compaction hammer

A "D" energy equivalent compaction hammer is used for this test. Dimensions

are shown in figure 1.5.5.1.3.2 and table 1.5.6.2 (Note: the compaction hammer has been

modified to match the mould used.)

1.5.5.1.5 Drying oven

The drying oven should be ventilated, with forced circulation of air or

inert gas, typically with a stainless-steel interior and capable of maintaining a

temperature within the range of 105°C ± 5°C.

1.5.5.1.6 Weighing balance

The weighing balance should be capable of weighing the sample and the

container, as received, with an accuracy of better than ± 5 g.

1.5.5.1.7 Pycnometer

Water pycnometry equipment is used to determine the density of the

full-sized coal (non-crushed) in accordance with AS 1289.3.5.1:2006. Specific equipment

required is as follows:

-

– a conical flask or density bottle of 250 mL capacity;

-

– a vacuum desiccator or other vacuum equipment;

-

– a drying oven set to 105°C to 110°C;

-

– balances: one with ± 0.05 g accuracy and the second with ± 1 g accuracy;

-

– a 0°C to 100°C thermometer;

-

– a 2.36 mm sieve (as noted in 1.5.5.1.2)

-

– a vacuum source;

-

– a water bath set at 60°C;

-

– distilled, demineralized or deionized water;

-

– a wash bottle containing water;

-

– a wire basket to hold the + 2.36 mm sample;

-

– a container filled with water to hold the wire basket without interference;

and

-

– a scale to weigh the basket both suspended in water and drained.

1.5.5.1.8 Containers for hand mixing and sample preparation

Sufficient heavy-duty plastic buckets with lids of not less than 10 L

capacity are required for storage and handling. Heavy-duty plastic bags (200 micron

thick or greater) are required for storage and hand mixing of samples.

1.5.5.1.9 Flat scraping device

A thin steel scraper is required for separating the remnant sample formed

in the extension piece lying above the top level of the mould. For ease of use, the

scraper should have dimensions of 160 mm wide, 200 mm long and 3 mm to 5 mm thick, such

as that shown in figure 1.5.5.1.9.

Figure 1.5.5.1.9 – Typical scraping device

1.5.5.1.10 Drying trays

Drying trays or pans should have a smooth surface, be free from

contamination and heat resistant, for example stainless steel or enamel. Dimensions

should be suitable to fit in the drying oven and ensure that the total sample can be

contained at a loading of about 1 g/cm2 of surface area.

1.5.5.1.11 Spray bottle

A suitable plastic bottle is required to add a mist spray of water to the

sample.

1.5.5.1.12 Gloves

Heat resistant gloves are required for removal of hot trays and dishes.

1.5.5.1.13 Sample divider

A suitable sample divider as specified in ISO 13909-4:2001 is required for

sub-sampling the primary sample and blending the reconstituted sample for testing.

1.5.5.2 Sampling and sample preparation

1.5.5.2.1 General

This procedure commences with receipt of sample of not less than 170 kg,

sealed in a heavy duty (200 micron thick) plastic bag and contained in a suitable drum

(e.g. 220 L). This packaging ensures the sample does not dry prior to TML determination.

1.5.5.2.2 Sample preparation

Representative samples are required that have been obtained using ISO

13909-4:2001 and if required may be partially air dried or partially dried at a

temperature of 40°C or less to reduce the water content to a starting point suitable for

dry sieving the coal with minimal fines adhering to the oversize fraction. For this

purpose, samples should not be dried below 6% total moisture. The representative

subsamples for the test should not be fully dried, except in the case of gross water

content determination.

1.5.5.2.2.1 Sample homogenization and division

Take the as-received sample and divide into individual subsamples using a

sample dividing apparatus as specified in ISO 13909-4:2001. Place these subsamples into

heavy-duty plastic bags.

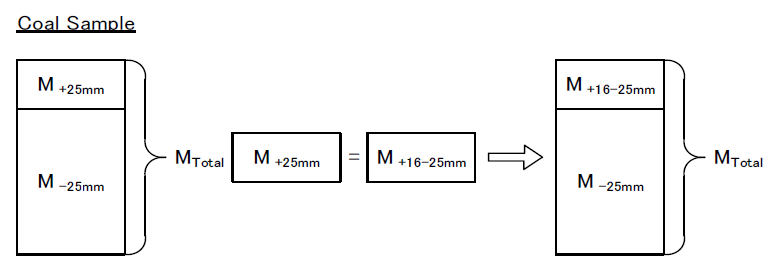

1.5.5.2.2.2 Reconstituted sample preparation procedure

When the sample contains particles above 25 mm, the reconstitution process

below should be applied.

In this process, particles above 25 mm are removed from the sample and

replaced by an equivalent mass of particles in the range 16 mm to 25 mm. Through this

process a final reconstituted sample of sufficient mass for TML testing is generated

which contains a maximum particle size of 25 mm.

One of two methods may be selected to generate the reconstituted sample:

-

.1 Split the entire as-received sample and then reconstitute; or

-

.2 Scalping off particles above 25 mm and substituting particles

between 16 mm and 25 mm from a separate subsample.

-

Method 1 Splitting the full as-received sample and

reconstitution

Step 1 Take the full as-received sample.

Step 2 Screen at 25 mm, 16 mm and 2.36 mm. If a 2.36 mm screen is

not available, a 2 mm screen may be used.

Step 3 Weigh each of the four size fractions and calculate the

percentage represented by each size fraction.

Step 4 Sub-divide from each size fraction below 25 mm the required

mass to create a 25 kg reconstituted sample using the sample size components

specified in table 1.5.5.2.2.2.1.

Table 1.5.5.2.2.2.1

Reconstitution size proportions (Method 1)

| Size fraction

|

Quantity

|

| -2.36 mm (or -2 mm)

|

percentage of this fraction in the original

sample

|

| 2.36 mm (or 2 mm) to 16 mm

|

percentage of this fraction

|

| 16 mm to 25 mm

|

percentage of this fraction plus the percentage of

+ 25 mm coal

|

Step 5 Combine each size fraction.

Step 6 Fully mix the reconstituted sample.

Step 7 Split the sample into approximately eight representative

subsamples and place each into a heavy duty plastic bag. These bags now contain

the sample for Proctor/Fagerberg testing.

Step 8 A sample of particles passing a 2.36 mm screen (or 2 mm if

2.36 mm is not available) is required for particle density pycnometry.

-

Method 2 Scalping particles above 25 mm and replacement with 16

mm to 25 mm particles

This method is described in figure 1.5.5.2.2.2 and table

1.5.5.2.2.2.2. The reconstitution process commences where the coal is initially

sieved into particle sizes larger than 25 mm and smaller than 25 mm. Coal

particles in the size range of 16 mm to 25 mm are extracted from separate

subsamples and reconstituted back into the original - 25 mm screened coal based

on a mass equivalent to the + 25 mm sized coal removed from the initial sample

to provide a final reconstituted sample of sufficient mass for TML testing.

Figure 1.5.5.2.2.2 – Overview of sample reconstitution (Method 2)

Table 1.5.5.2.2.2.2

Sample reconstitution (Method 2)

| Step

|

Example

|

| 1

Generate a sample of approximately 25 kg which is sufficient to

complete approximately eight Proctor/Fagerberg tests.

|

Assumes each subsample bag contains 8 kg to 10 kg.

|

| 2

Screen this sample at 25 mm, ensuring minimal adhering fines on the

+ 25 mm fraction. Weigh the + 25 mm coal.

|

For a coal containing 20% + 25 mm material, approximately 5 kg of

initial sample is removed.

|

| 3

Create sufficient 16 mm to 25 mm coal by screening one or more

further subsample bags of coal at 16 mm and 25 mm.

|

In the above example, 5 kg of 16 mm to 25 mm coal is

required.

|

| 4

Extract an amount of 16 mm to 25 mm coal of mass equal to the mass

of + 25 mm removed in step b) within ± 0.05 kg using a rotary

sample divider or similar device, recombining sector trays as

required to obtain the required mass.

|

5 kg in the above case.

|

| 5

Add the mass of 16 mm to 25 mm coal from step d) to the -25 mm coal

from step 2. Blend and divide into approximately eight test

portions using a rotary sample divider or similar device.

|

|

6

Place each reconstituted test portion in heavy duty plastic bags,

label and seal.

These now become the test

portions used for Proctor/Fagerberg testing.

|

Each bag should contain approximately 2.5 kg to 3 kg of

reconstituted - 25 mm coal.

|

| 7

Discard the + 25 mm and - 16 mm coal.

|

|

1.5.5.2.3 Initial moisture

Initial moisture is to be determined on a test portion from table

1.5.5.2.2.2.2 step 5 using the method provided in ISO 589:2008. This moisture

value provides a guide to the moisture steps required to develop the

Proctor/Fagerberg compaction curve.

1.5.5.2.4 Particle density measurement

In accordance with water pycnometer standard AS 1289.3.5.1:2006,

measure the density of solids on the full size range (non-crushed) coal. The

density of solids is used for determining the void ratio for plotting

compaction curves. The recommended methodology is described below:

-

.1 Generate a full particle size sample of approximately

10 kg, weigh and then screen the entire contents at 2.36 mm. If a 2.36

mm screen is not available, a 2 mm screen may be substituted. Record

the following:

-

.1 the total mass of the material;

-

.2 the mass of + 2.36 mm material; and

-

.3 the mass of - 2.36 mm material.

-

.2 Calculate the percentage of - 2.36 mm coal in the

sample.

-

.3 Divide the + 2.36 mm coal into two test portions using

sample dividing apparatus as specified in ISO 13909-4:2001 such as a

rotary sample divider. Place each test portion in a heavy duty plastic

bag and label.

-

.4 Divide the - 2.36 mm coal into two test portions, place

each test portion in a heavy duty plastic bag and label.

-

.5 Determine the density of solids of the + 2.36 mm

fraction following the method described in Section 5.2 of AS

1289.3.5.1:2006. As noted in the standard, duplicate determinations

are required.

-

.6 Determine the density of solids of the - 2.36 mm

fraction using the method described in Section 5.1 of the above

standard with the following clarifications:

-

.1 Use of 250 mm conical or pycnometry flasks

is recommended.

-

.2 From the sample bag pour 1 L of coal into a

beaker of known tare weight.

-

.3 Weigh the 1 L sample and calculate the

approximate bulk density of the material.

-

.4 Remove a portion of the sample (nominally a

mass in kilograms of 0.18 x bulk density) and place into the

flask, and complete the pycnometry analysis.

-

.5 A water bath temperature of 60°C is

recommended.

-

.7 Calculate the density of solids using the method in

Section 6 of AS 1289.3.5.1:2006.

1.5.5.3 Test procedure

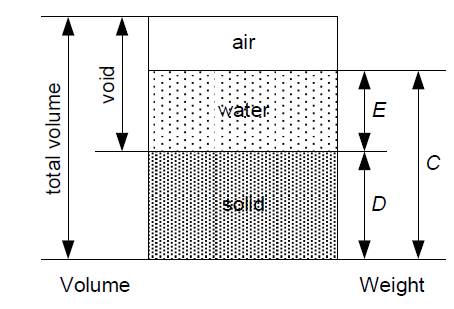

1.5.5.3.1 Variables and definitions

The variables and definitions used in the determination of TML are

summarized in table 1.5.5.3.1 with some key variables as illustrated in figure

1.5.5.3.1.

Table 1.5.5.3.1 – Summary

of variables and definitions

| Variable

|

Unit

|

Symbol/value used in calculations

|

| Mass of empty cylinder and base

|

g

|

A

|

| Mass of cylinder, base and tamped test portion

|

g

|

B

|

| Wet mass of test portion in the mould

|

g

|

C = B − A

|

| Wet mass of test portion removed from the mould

|

g

|

C1

|

| Dry mass of test portion removed from the mould

|

g

|

D1

|

| Gross water content

|

%

|

W1

|

| Dry mass of test portion in the mould

|

g

|

D

|

| Mass of water in the mould

|

g

|

E

|

| Volume of cylinder

|

cm3

|

V

|

| Density of solids

|

g/cm3

|

d

|

| Density of water

|

g/cm3

|

ρw

|

Figure 1.5.5.3.1 – Illustration of key variables

1.5.5.3.2 Establishment of the initial compaction point

The initial compaction point is obtained using the first test

portion of the reconstituted material at the initial moisture content. For each

compaction point determination, all steps in the procedure from packing the

mould to weighing the mould and sample are to be completed at the same time

without breaks. In any case, coal should not be left in the mould for longer

than 30 min prior to weighing.

The test procedure is as follows:

-

| Step 1

|

Clean the mould, collar and base plate.

Inspect and clean the hammer and ensure that it moves

freely in the guide tube.

|

| Step 2

|

Determine the mass, A, of the empty

cylinder, comprising the mould plus base plate.

|

| Step 3

|

Assemble the mould, collar and base plate and

place the assembly on a stable bench.

|

| Step 4

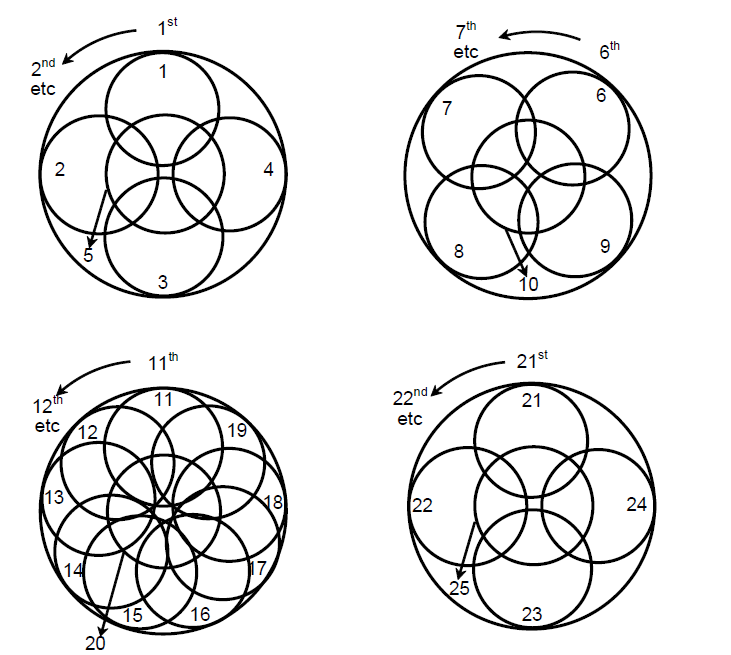

|

Place approximately 0.5 L (one fifth of the

full 2.5 L) of the test portion into the mould, level, and

then tamp uniformly over the surface by dropping the

hammer 25 times vertically through the full height of the

guide pipe, moving the guide pipe to a new position after

each drop. The required pattern for even compaction of

each layer in the mould is shown in figure

1.5.5.3.2.

|

| Step 5

|

Repeat step 4 four more times so that there

are 5 layers of material in the mould. Ensure that the

compacted test portion with the final layer is above the

top of the compaction mould whilst the extension piece is

still attached.

|

| Step 6

|

When the last layer has been tamped, remove

the extension piece taking care not to disturb the

compacted test portion inside. Level the compacted test

portion to the top of the mould using the flat scraping

device, ensuring that any large particles that may hinder

levelling of the test portion are removed and replaced

with material contained in the extension piece and

re-level. If any holes in the surface are still observed

after levelling, they should be manually filled with finer

material contained in the extension piece. Care should be

taken to avoid any further compaction of the test

portion.

|

| Step 7

|

Determine the mass, B, of the mould

and compacted coal and then calculate the mass, C,

of the wet test portion using the equation:

|

|

|

|

(1)

|

| Step 8

|

When the weight of the cylinder with the

tamped test portion has been determined, remove the test

portion from the mould, determine the mass of the wet test

portion, C1, and dry the entire test portion in

an oven at 105°C until constant mass is achieved. After

drying, determine the weight, D1, of the dried

test portion and then calculate the percentage gross water

content, W1, as follows:

|

|

|

|

(2)

|

| Step 9

|

Using the calculated gross water content,

calculate the mass of the dry test portion in the mould,

D, using the equation:

|

|

|

|

(3)

|

| Step 10

|

Calculate the mass, E, of water in the mould

using the equation:

|

|

|

|

(4)

|

| Step 11

|

Discard the used coal sample. Coal from a

previously compacted test portion should not be

reused.

Figure 1.5.5.3.2 – Recommended compaction

patterns

|

1.5.5.3.3 Establishment of complete compaction curve

The range of water contents should be adjusted so that partially

dry to almost saturated test portions are obtained. Care should be taken to

follow the precaution in 1.5.5.3.2 above regarding prompt completion of each

point in the compaction curve.

The test procedure is as follows:

-

Step 1 For each compaction test, a predetermined amount of

water is added to the test portion (approximately 2.5 kg) in a heavy

duty plastic bag. The water quantity added is that required to

increase the moisture content to the target value for the next test.

The water should be added as a mist spray to the surface of the

individual test portions. The water at this point should be added

slowly and in small quantities, as the introduction of large amounts

of water may induce localized compaction behaviour.

-

Step 2 After the calculated water addition, the test

portion should then be mixed thoroughly in the plastic bag by sealing

the bag and turning it over repeatedly for 5 MIN.

-

Step 3 The test portion should then be allowed to

equilibrate for a minimum of 12 hours prior to compaction testing.

-

Step 4 Repeat steps 1 to 11 from 1.5.5.3.2.

-

Step 5 Repeat the test between four and seven times using

the other prepared test portions with different water contents to

obtain at least five points on the compaction curve. The water

contents should be chosen so that:

-

.1 at least one point corresponds to moisture

content higher than the optimum moisture content (OMC) or

than the value corresponding to 70% of degree of saturation

(S), in order to satisfactorily define the

compaction curve; and

-

.2 at least one point corresponds to the degree

of saturation (S) between 70% and 80%, in order to

effectively assess the PFD70 value.

A point close to a degree of saturation (S) of 80%

will also assist accurate assessment if the OMC is greater than 70%.

1.5.5.3.4 Visual appearance of coal in the cylindrical mould

In order for the test to obtain a PFD70 value, all tests conducted

at or below the PFD70 moisture value should have an even moisture distribution

throughout the cylindrical mould.

Two examples of tests using samples of the same coal at different

moisture contents are shown in figure 1.5.5.3.4.1. The left-hand photograph

shows a coal specimen at a relatively low degree of saturation. Note that the

coal remains in place following removal of the collar. The right-hand

photograph shows a specimen near or possibly above 70% degree of saturation.

Once again the coal remains in place following removal of the collar. Both

tests provided valid points on the compaction curve.

Figure 1.5.5.3.4.1 – Photographs showing valid tests for a partially

saturated test portion (left) and a near fully saturated test portion

(right)

Coals where water passes through the spaces between particles

exhibit moisture migration within the Proctor/Fagerberg cylindrical mould.

Moisture migration may take place when the degree of saturation of the specimen

is less than 70%.

Evidence of moisture migration is from visual observation at the

completion of each test as follows:

-

.1 moisture leakage from the base of the mould is evident

as shown in figure 1.5.5.3.4.2; and

-

.2 The portion above the top of the cylindrical mould

appears unsaturated and the test portion maintains its structure

without deformation or movement.

In this case, moisture migration has occurred and hence for this

coal water passes through the spaces between particles.

Figure 1.5.5.3.4.2 – Test showing water leakage from the base of the

cylindrical mould indicating moisture migration

1.5.5.3.5 Calculation of key parameters for determination of

compaction curve

Carry out the following calculations for each compaction test:

|

d |

= |

density of solids, g/cm3 (t/m3) by

pycnometry (see 1.5.5.2.4) |

|

γ |

= |

dry bulk density, g/cm3

(t/m3) |

| = |

D/V |

|

ev |

= |

net water content (percentage by volume) |

| = |

(E/D) × 100 × d/ρw

where ρw= density of water,

g/cm3 (t/m3)

|

|

e |

= |

void ratio (volume of voids divided by volume of

solids) |

| = |

(d/γ) -1 |

|

S |

= |

degree of saturation (percentage by volume) |

| = |

ev /e |

|

W1 |

= |

gross (total) water content (percentage by mass) (see

1.5.5.3.2, Step 8). |

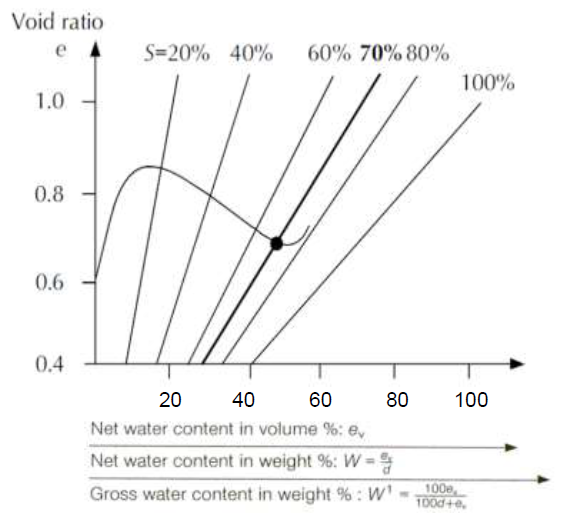

1.5.5.3.6 Presentation of compaction results

Record all the compaction test results in a suitable spreadsheet

(such as that shown in table 1.5.6.1) and from this spreadsheet create a

compaction curve as shown in figure 1.5.5.3.6 by plotting the calculated void

ratio (e) for each compaction test on the ordinate against either the

net or gross water content plotted on the abscissa.

The lines in figure 1.5.5.3.6 correspond to plots of void ratio

(e) versus net water content (ev) at 20%,

40%, 60%, 70%, 80% and 100% degree of saturation (S). These lines are

calculated at five values of void ratio using the formulae in 1.5.5.3.7. (Note:

These lines corresponding to degree of saturation will be curved in the case of

plotting gross water content on the abscissa.)

Figure 1.5.5.3.6 – Typical compaction curve

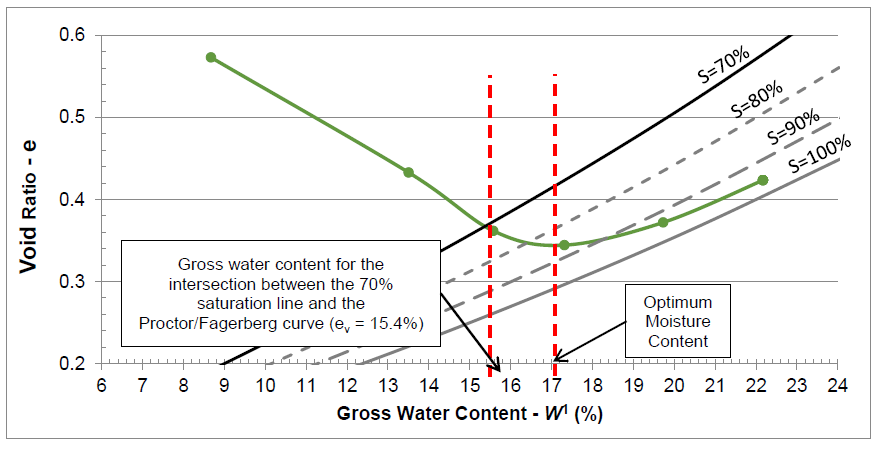

1.5.5.3.7 Sample compaction curve

An example of the results obtained when applying the Modified

Proctor/Fagerberg test to a coal sample is provided in table 1.5.6.1, with the

corresponding compaction curve and the 70% degree of saturation line plotted as

described below.

The preferred approach to presenting the results is to plot the

void ratio (

e) against the gross water content (

W1)

allowing moisture for any saturation level to be read directly from the plot as

gross water content. This approach is shown in figure 1.5.5.3.7. The saturation

lines are plotted according to the equation:

The intercept of the compaction curve with the 70% degree of

saturation line in figure 1.5.5.3.7 occurs at a gross water content of 15.4%,

which is the transportable moisture limit (TML). For this example, the optimum

moisture content (OMC) occurs at a degree of saturation of about 85%.

Figure 1.5.5.3.7 – Example of a measured compaction curve for void ratio

versus gross water content with the 70%, 80%, 90% and 100% degree of

saturation lines plotted

1.5.5.3.8 Determination of transportable moisture limit

1.5.5.3.8.1 Determination of PFD70 moisture content

The PFD70 value is determined as the gross (total) water content

corresponding to the intersection of the compaction curve and the line S

= 70% saturation. The optimum moisture content (OMC) is the gross (total)

moisture content corresponding to the maximum compaction (maximum dry density

and minimum void ratio) under the specified compaction condition.

The test procedure is applicable for determination of coal TML

where the degree of saturation corresponding to the OMC of the coal is at or

greater than 70%. Where the OMC lies below 70% degree of saturation, this test

is not applicable for the specific coal and the PFD70 may overstate the TML. In

such cases, the certificate of analysis should state that the OMC is below 70%

saturation and the shipper should consult with an appropriate authority.

1.5.5.3.8.2 Cases where the highest determinable point on the

compaction curve lies below 70% saturation

In coals where there is visual evidence that water passes through

the spaces between particles and the compaction curve does not extend to or

beyond the 70% degree of saturation line, the coal is deemed to be

free-draining and a TML value is not applicable. By reference to 7.2.2 of this

Code, such coals are cargoes which are not liable to liquefy, and hence are

classified as group B only.

1.5.6 Test report

The test report from application of the modified Proctor/Fagerberg

test procedure should include the following information:

-

.1 identification of the sample;

-

.2 a unique reference to this test procedure;

-

.3 reference to the appropriate standard adopted for

determining the density of the solids:

either:

-

.1 the transportable moisture limit (TML) of the

sample, expressed as the gross water content as a percentage of the

sample by mass;

-

.2 the OMC lies below 70% degree of saturation and this

test procedure is not applicable; or

-

.3 a statement that the test indicated that water

passes through the spaces between particles at moisture content

below the value corresponding to 70% degree of saturation, and the

coal is therefore group B only.

-

.4 The solids density d in g/cm3.