Section 1 Calculation procedure

1.3 Hence, maximum

bending moment, M

S' is given by:

Assumed shell laminate:

5 x 800/300 combination

mats

|

G

c

|

= |

0,5 (WR in combination mat) |

|

G

c

|

= |

0,33 (CSM in combination mat) |

1 x 450 CSM adjacent to gel coat

Total thickness, t

p = 9,132

mm

The effective width of attached plating 2b

1 from Pt 8, Ch 3,1.7.1 of the Rules for Special Service Craft

for single skin construction is:

|

b

1

|

= |

0 . 5b

w + 10t

ap

|

| = |

0,5 x 120 + 10 x 9,132 |

| = |

151 mm |

Hence, apply 302 mm attached plating.

Consider

typical layup over top hat stiffener:

| 450 g/m2 CSM

|

@

|

G

c = 0,33 first ply over former

|

| 800 g/m2 WR

|

@

|

G

c = 0,5

|

| 800 g/m2 WR

|

@

|

G

c = 0,5

|

| 600 g/m2 UDT

|

@

|

G

c = 0,54

|

| 600 g/m2 UDT

|

@

|

G

c = 0,54

|

| 800 g/m2 WR

|

@

|

G

c = 0,5

|

| 800 g/m2 WR

|

@

|

G

c = 0,5 top ply

|

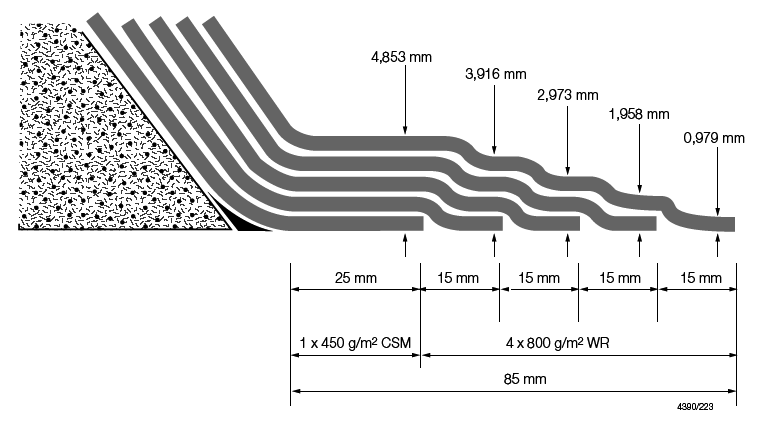

1.5 The stiffener

bonding is to be in accordance with Pt 8, Ch 3, 1 General of the Rules for Special Service Craft and a typical

arrangement is shown in Figure 5.1.3 Typical stiffener bonding arrange.

To simplify the calculation of the stiffness of the overall section

the tapered bonding is assumed to be an effective constant thickness.

1.6 The effective thickness of the bonding is calculated

as:

The boundary bonding may be approximated to a thickness

of 3,15 mm over an (85 x 2) mm width to account for both flanges.

The majority of the flange comprises of woven rovings and it may be

assumed that the tensile modulus is 145000 N/mm2. The discrepancy

is negligible since the element is very close to the neutral axis.

1.7 The effective depth and width of the

web used in the idealised section are:

|

d

web

|

= |

70 effective thickness on bonding |

|

t

web

|

= |

2 x (0,937 + 4 x 0,979) |

1.8 Now the web consists of two types of reinforcements,

namely one ply of CSM and four plies of woven rovings. The majority

of the web will be in compression and the overall modulus of elasticity

may be calculated in accordance with Pt 8, Ch 3, 1 General of the Rules for Special Service Craft.

The web may now be treated as a single laminate item

having an overall compressive modulus, given above.

1.9 The laminate

section modulus calculation is shown in Table 5.1.1 Initial tabulation of 'top-hat'

stiffener calculations. The tabulation consists of each element having the compressive

moduli in the section above the neutral axis and tensile moduli below.

The actual breadth of each element must be entered to calculate the

overall section properties. The tabulation corresponds to the idealised

section in Figure 5.1.2 Idealised section.

Figure 5.1.3 Typical stiffener bonding arrange

1.10 The tabulation

considers the entire section and calculates all moments about the

base, which is taken to be the outer (wet) surface. The stiffness, EI, of the entire section, about the neutral axis, is determined

using the parallel axis theorem:

In general,

|

EI

sect

|

= |

ΣEI

base (Σ Etb)

x y

2

|

where

|

y

|

= |

distance

of neutral axis above the base (mm) |

1.11 From the tabulation:

|

EI

sect

|

= |

70480944121 53219882 x (22,44)2

|

|

EI

sect

|

= |

4,368 x 106 Ncm4/mm2

|

1.12 From Pt 8, Ch 3, 1 General of the Rules for Special Service Craft the individual

layer stresses are determined from:

The calculation of the stresses in individual layers

becomes:

where

|

E

i

|

= |

modulus of elasticity of layer (N/mm2)

|

|

y

i

|

= |

distance of layer from the neutral axis (mm) |

Table 5.1.1 Initial tabulation of 'top-hat'

stiffener calculations

|

|

Ply No.

|

Description

|

G

c

|

Weight

|

t

|

Breadth,

|

Lever @

|

E

|

t.b

|

E.t.b

|

E.t.b.x

|

I @

|

EI @

|

|

|

(g/m2)

|

(mm)

|

b (mm)

|

base, x (mm)

|

(N/mm2)

|

|

|

|

base

|

base

|

Dry

see Note

|

1

|

WR

|

0,5

|

800

|

0,979

|

80

|

84,816

|

14000

|

78,32

|

1096480

|

92998499

|

563414,4

|

7887801805

|

|

|

2

|

WR

|

0,5

|

800

|

0,979

|

80

|

83,837

|

14000

|

78,32

|

1096480

|

91925046

|

550483,0

|

7706761655

|

|

|

3

|

UDT

|

0,54

|

600

|

0,660

|

80

|

83,017

|

20748

|

52,80

|

1095494

|

90944659

|

363890,1

|

7549992490

|

|

|

4

|

UDT

|

0,54

|

600

|

0,660

|

80

|

82,357

|

20748

|

52,80

|

1095494

|

90221632

|

358127,2

|

7430422738

|

|

|

5

|

WR

|

0,5

|

800

|

0,979

|

80

|

81,538

|

14000

|

78,32

|

1096480

|

89404238

|

520706,1

|

7289885632

|

|

|

6

|

WR

|

0,5

|

800

|

0,979

|

80

|

80,559

|

14000

|

78,32

|

1096480

|

88330784

|

508277,4

|

7115883045

|

|

|

7

|

CSM

|

0,33

|

450

|

0,937

|

80

|

79,601

|

7200

|

74,96

|

539712

|

42961345

|

474970,0

|

3419784035

|

|

|

8

|

Web

|

0,5

|

|

66,85

|

9,706

|

45,707

|

12687

|

648,85

|

8231910

|

376255932

|

1597160,7

|

20263177372

|

|

|

9

|

bonding

|

0,5

|

|

3,15

|

170

|

10,707

|

14500

|

535,50

|

7764750

|

83137178

|

61832,4

|

896570245

|

|

|

10

|

WR

|

0,5

|

800

|

0,979

|

302

|

8,643

|

14500

|

295,66

|

4287041

|

37050752

|

22107,1

|

320553529

|

|

|

11

|

CSM

|

0,33

|

300

|

0,625

|

302

|

7,840

|

6950

|

188,75

|

1311813

|

10285266

|

11609,3

|

80684330

|

|

|

12

|

WR

|

0,5

|

800

|

0,979

|

302

|

7,039

|

14500

|

295,66

|

4287041

|

30174338

|

14670,7

|

212724485

|

|

|

13

|

CSM

|

0,33

|

300

|

0,625

|

302

|

6,236

|

6950

|

188,75

|

1311813

|

8181119

|

7347,4

|

51064249

|

|

|

14

|

WR

|

0,5

|

800

|

0,979

|

302

|

5,435

|

14500

|

295,66

|

4287041

|

23297924

|

8755,5

|

126954976

|

|

|

15

|

CSM

|

0,33

|

300

|

0,625

|

302

|

4,632

|

6950

|

188,75

|

1311813

|

6076971

|

4056,7

|

28194272

|

|

|

16

|

WR

|

0,5

|

800

|

0,979

|

302

|

3,831

|

14500

|

295,66

|

4287041

|

16421511

|

4361,7

|

63245002

|

|

|

17

|

CSM

|

0,33

|

300

|

0,625

|

302

|

3,028

|

6950

|

188,75

|

1311813

|

3972824

|

1737,3

|

12074400

|

|

|

18

|

WR

|

0,5

|

800

|

0,979

|

302

|

2,227

|

14500

|

295,66

|

4287041

|

9545097

|

1489,3

|

21594564

|

|

|

19

|

CSM

|

0,33

|

300

|

0,625

|

302

|

1,424

|

6950

|

188,75

|

1311813

|

1868677

|

389,2

|

2704632

|

Wet

see Note

|

20

|

CSM

|

0,286

|

450

|

1,112

|

302

|

0,556

|

6290

|

335,82

|

2112333

|

1174457

|

138,4

|

870664

|

| TOTALS

|

|

|

|

|

85,305

|

|

|

|

4436,05

|

53219882

|

1194228249

|

|

70480944121

|

Note Position of neutral axis above base  22,44 mm above base Tensile modulus of elasticity

of section 22,44 mm above base Tensile modulus of elasticity

of section  11997 N/mm2 11997 N/mm2

Note Stiffness EI of section about NA = 4368304 N

cm4/mm2

|

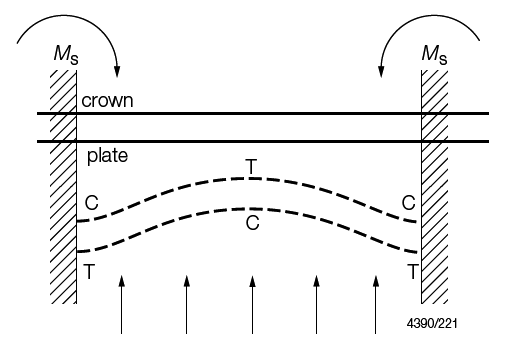

Figure 5.1.4 Regions of tension (T) and compression (C) in example model

|