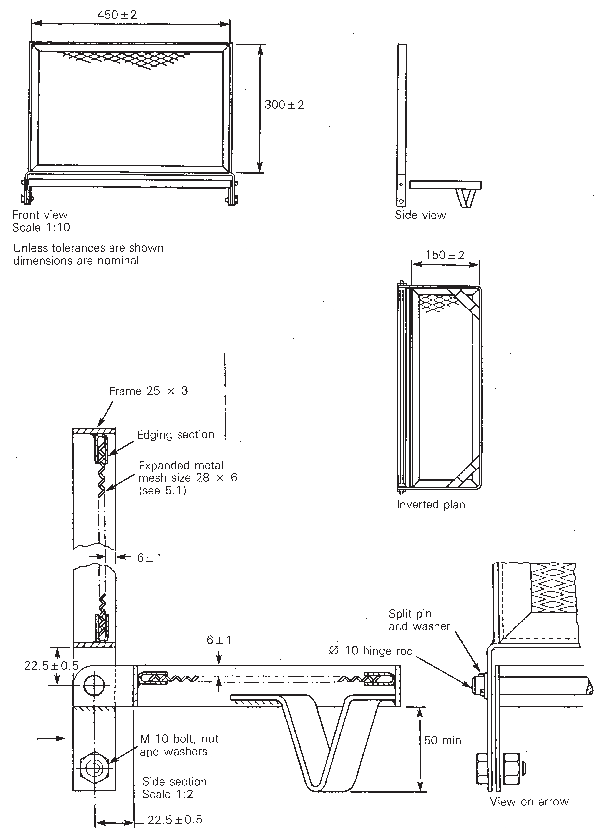

A suitable test rig is illustrated in Figures 1 and 2. It shall consist of two rectangular

frames hinged together and capable of being locked at right angles

to each other.

Figure 1 Test rig

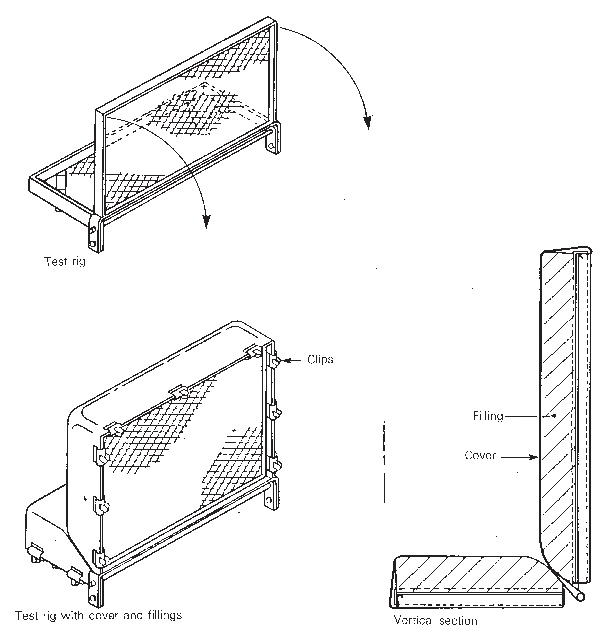

Figure 2 Test rig assembly

The frames shall be made from nominal 25 mm x 3 mm steel

flat bar and shall securely hold expanded steel platforms set 6 ±

1 mm below the top edge of the frames.

Note:

The size of the mesh of the

expanded steel is not critical, but a mesh size across the diagonals

of approximately 28 mm x 6 mm has been found to be suitable.

The internal width and height of the back frame shall be

450 ± 2 mm x 300 ± 2 mm and the width and depth of the

base frame 450 ± 2 mm x 150 ± 2 mm. A standard edging

section may be used around the expanded steel to give protection and

greater rigidity.

The sides of the frame shall extend beyond the back of each

frame to provide for the hinge holes and to form the back legs. The

hinge rod shall be of nominal l00 mm diameter steel, continuous across

the back of the rig, and its axis 22.5 ± 0.5 mm beyond the

back member of each frame.

The frames shall be lockable at right angles by a bolt or

pin through each of the pairs of members forming the back legs. The

front legs may be welded across the front corners of the base frame.

The height of the legs shall be such as to leave a gap not less than

50 mm high between the base frame and the supporting surface.

For the tests, the rig shall be sited within the enclosure

(see 4.2) and the testing shall

be performed in a substantially draught-free environment permitting

an adequate supply of air.