16.1 General

16.1.1 The manufacture, testing, inspection and documentation shall be

in accordance with recognized standards and the regulations given in this Code.

16.1.2 Where post-weld heat treatment is specified or required, the properties of the

base material shall be determined in the heat treated condition, in accordance with

the applicable tables of chapter 7, and the weld properties shall be determined in

the heat treated condition in accordance with 16.3. In cases where a post-weld heat

treatment is applied, the test regulations may be modified at the discretion of the

Administration.

16.2 General test regulations and

specifications

16.2.1 Tensile test

16.2.1.1 Tensile testing shall be carried out in accordance with

recognized standards.

16.2.1.2 Tensile strength, yield stress and elongation shall be to the

satisfaction of the Administration. For carbon-manganese steel and other materials

with definitive yield points, consideration shall be given to the limitation of the

yield to tensile ratio.

16.2.2 Toughness test

16.2.2.1 Acceptance tests for metallic materials shall include Charpy V-notch

toughness tests unless otherwise specified by the Administration. The specified

Charpy V-notch regulations are minimum average energy values for three full size (10

mm × 10 mm) specimens and minimum single energy values for individual specimens.

Dimensions and tolerances of Charpy V-notch specimens shall be in accordance with

recognized standards. The testing and regulations for specimens smaller than 5.0 mm

in size shall be in accordance with recognized standards. Minimum average values for

sub-sized specimens shall be:

| Charpy V-notch specimen size (mm)

|

Minimum average energy of three

specimens

|

| 10 x 10

|

KV

|

| 10 x 7.5

|

5/6 KV

|

| 10 x 5.0

|

2/3 KV

|

- where:

- KV = the energy values (J) specified in tables 7.1 to 7.4.

Only one individual value may be below the specified average value, provided it is

not less than 70% of that value.

16.2.2.2 For base metal, the largest size Charpy V-notch specimens possible for the

material thickness shall be machined with the specimens located as near as

practicable to a point midway between the surface and the centre of the thickness

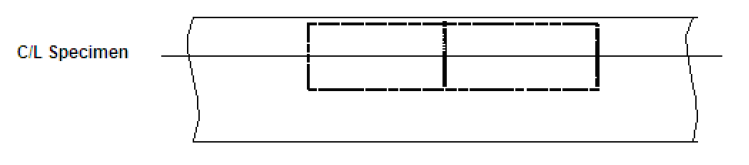

and the length of the notch perpendicular to the surface as shown in figure

16.1.

Figure 16.1 – Orientation of base metal test specimen

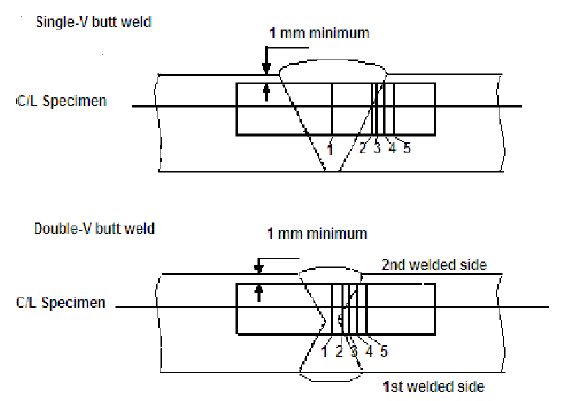

16.2.2.3 For a weld test specimen, the largest size Charpy V-notch specimens possible

for the material thickness shall be machined, with the specimens located as near as

practicable to a point midway between the surface and the centre of the thickness.

In all cases the distance from the surface of the material to the edge of the

specimen shall be approximately 1 mm or greater. In addition, for double-V butt

welds, specimens shall be machined closer to the surface of the second welded

section. The specimens shall be taken generally at each of the following locations,

as shown in figure 16.2, on the centreline of the welds, the fusion line and 1 mm, 3

mm and 5 mm from the fusion line.

Figure 16.2 – Orientation of weld test specimen

Notch locations in figure 16.2:

- .1 centreline of the weld;

- .2 on fusion line;

- .3 in heat-affected zone (HAZ), 1 mm from fusion line;

- .4 in HAZ, 3 mm from fusion line; and

- .5 in HAZ, 5 mm from fusion line.

16.2.2.4 If the average value of the three initial Charpy V-notch specimens fails to

meet the stated regulations, or the value for more than one specimen is below the

required average value, or when the value for one specimen is below the minimum

value permitted for a single specimen, three additional specimens from the same

material may be tested and the results combined with those previously obtained to

form a new average. If this new average complies with the regulations and if no more

than two individual results are lower, than the required average and no more than

one result is lower than the required value for a single specimen, the piece or

batch may be accepted.

16.2.3 Bend test

16.2.3.1 The bend test may be omitted as a material acceptance test, but

is required for weld tests. Where a bend test is performed, this shall be done in

accordance with recognized standards.

16.2.3.2 The bend tests shall be transverse bend tests, which may be

face, root or side bends at the discretion of the Administration. However,

longitudinal bend tests may be required in lieu of transverse bend tests in cases

where the base material and weld metal have different strength levels.

16.2.4 Section observation and other testing

Macrosection, microsection observations and hardness tests may also be

required by the Administration, and they shall be carried out in accordance with

recognized standards, where required.

16.3 Welding of metallic materials

and non-destructive testing for the fuel containment system

16.3.1 General

This section shall apply to primary and secondary barriers only,

including the inner hull where this forms the secondary barrier. Acceptance testing

is specified for carbon, carbon-manganese, nickel alloy and stainless steels, but

these tests may be adapted for other materials. At the discretion of the

Administration, impact testing of stainless steel and aluminium alloy weldments may

be omitted and other tests may be specially required for any material.

16.3.2 Welding consumables

Consumables intended for welding of fuel tanks shall be in accordance

with recognized standards. Deposited weld metal tests and butt weld tests shall be

required for all consumables. The results obtained from tensile and Charpy V-notch

impact tests shall be in accordance with recognized standards. The chemical

composition of the deposited weld metal shall be recorded for information.

16.3.3 Welding procedure tests for fuel tanks and process pressure

vessels

16.3.3.1 Welding procedure tests for fuel tanks and process pressure

vessels are required for all butt welds.

16.3.3.2 The test assemblies shall be representative of:

16.3.3.3 For butt welds in plates, the test assemblies shall be so

prepared that the rolling direction is parallel to the direction of welding. The

range of thickness qualified by each welding procedure test shall be in accordance

with recognized standards. Radiographic or ultrasonic testing may be performed at

the option of the fabricator.

16.3.3.4 The following welding procedure tests for fuel tanks and

process pressure vessels shall be done in accordance with 16.2 with specimens made

from each test assembly:

-

.1 cross-weld tensile tests;

-

.2 longitudinal all-weld testing where required by the recognized standards;

-

.3 transverse bend tests, which may be face, root or side bends. However,

longitudinal bend tests may be required in lieu of transverse bend tests in

cases where the base material and weld metal have different strength levels;

-

.4 one set of three Charpy V-notch impacts, generally at each of the

following locations, as shown in figure 16.2:

-

.1 centreline of the welds;

-

.2 fusion line;

-

.3 1 mm from the fusion line;

-

.4 3 mm from the fusion line; and

-

.5 5 mm from the fusion line;

- .5 macrosection, microsection and hardness survey may also be

required.

16.3.3.5 Each test shall satisfy the following:

-

.1 tensile tests: cross-weld tensile strength is not to be less than the

specified minimum tensile strength for the appropriate parent materials. For

aluminium alloys, reference shall be made to 6.4.12.1.1.3 with regard to the

regulations for weld metal strength of under-matched welds (where the weld

metal has a lower tensile strength than the parent metal). In every case,

the position of fracture shall be recorded for information;

-

.2 bend tests: no fracture is acceptable after a 180° bend over a former of a

diameter four times the thickness of the test pieces; and

-

.3 Charpy V-notch impact tests: Charpy V-notch tests shall be conducted at

the temperature prescribed for the base material being joined. The results

of weld metal impact tests, minimum average energy (KV), shall be no less

than 27 J. The weld metal regulations for sub-size specimens and single

energy values shall be in accordance with 16.2.2. The results of fusion line

and heat affected zone impact tests shall show a minimum average energy (KV)

in accordance with the transverse or longitudinal regulations of the base

material, whichever is applicable, and for sub-size specimens, the minimum

average energy (KV) shall be in accordance with 16.2.2. If the material

thickness does not permit machining either full-size or standard sub-size

specimens, the testing procedure and acceptance standards shall be in

accordance with recognized standards.

16.3.3.6 Procedure tests for fillet welding shall be in accordance with

recognized standards. In such cases, consumables shall be so selected that exhibit

satisfactory impact properties.

16.3.4 Welding procedure tests for piping

Welding procedure tests for piping shall be carried out and shall be

similar to those detailed for fuel tanks in 16.3.3.

16.3.5 Production weld tests

16.3.5.1 For all fuel tanks and process pressure vessels except membrane

tanks, production weld tests shall generally be performed for approximately each 50

m of butt-weld joints and shall be representative of each welding position. For

secondary barriers, the same type production tests as required for primary tanks

shall be performed, except that the number of tests may be reduced subject to

agreement with the Administration. Tests, other than those specified in 16.3.5.2 to

16.3.5.5 may be required for fuel tanks or secondary barriers.

16.3.5.2 The production tests for types A and B independent tanks shall

include bend tests and, where required for procedure tests, one set of three Charpy

V-notch tests. The tests shall be made for each 50 m of weld. The Charpy V-notch

tests shall be made with specimens having the notch alternately located in the

centre of the weld and in the heat affected zone (most critical location based on

procedure qualification results). For austenitic stainless steel, all notches shall

be in the centre of the weld.

16.3.5.3 For type C independent tanks and process pressure vessels,

transverse weld tensile tests are required in addition to the tests listed in

16.3.5.2. Tensile tests shall meet regulation 16.3.3.5.

16.3.5.4 The quality assurance/quality control (QA/QC) program shall

ensure the continued conformity of the production welds as defined in the material

manufacturers quality manual (QM).

16.3.5.5 The test regulations for membrane tanks are the same as the

applicable test regulations listed in 16.3.3.

16.3.6 Non-destructive testing

16.3.6.1 All test procedures and acceptance standards shall be in

accordance with recognized standards, unless the designer specifies a higher

standard in order to meet design assumptions. Radiographic testing shall be used in

principle to detect internal defects. However, an approved ultrasonic test procedure

in lieu of radiographic testing may be conducted, but in addition supplementary

radiographic testing at selected locations shall be carried out to verify the

results. Radiographic and ultrasonic testing records shall be retained.

16.3.6.2 For type A independent tanks where the design temperature is

below -20°C, and for type B independent tanks, regardless of temperature, all full

penetration butt welds of the shell plating of fuel tanks shall be subjected to

non-destructive testing suitable to detect internal defects over their full length.

Ultrasonic testing in lieu of radiographic testing may be carried out under the same

conditions as described in 16.3.6.1.

16.3.6.3 In each case the remaining tank structure, including the welding

of stiffeners and other fittings and attachments, shall be examined by magnetic

particle or dye penetrant methods as considered necessary.

16.3.6.4 For type C independent tanks, the extent of non-destructive

testing shall be total or partial according to recognized standards, but the

controls to be carried out shall not be less than the following:

16.3.6.5 The quality assurance/quality control (QA/QC) program shall ensure the

continued conformity of the non-destructive testing of welds, as defined in the

material manufacturer's quality manual (QM).

16.3.6.6 Inspection of piping shall be carried out in accordance with the regulations

of chapter 7.

16.3.6.7 The secondary barrier shall be non-destructive tested for internal defects

as considered necessary. Where the outer shell of the hull is part of the secondary

barrier, all sheer strake butts and the intersections of all butts and seams in the

side shell shall be tested by radiographic testing.

16.4 Other regulations for

construction in metallic materials

16.4.1 General

Inspection and non-destructive testing of welds shall be in accordance

with regulations in 16.3.5 and 16.3.6. Where higher standards or tolerances are

assumed in the design, they shall also be satisfied.

16.4.2 Independent tank

For type C tanks and type B tanks primarily constructed of bodies of

revolution the tolerances relating to manufacture, such as out-of-roundness, local

deviations from the true form, welded joints alignment and tapering of plates having

different thicknesses, shall comply with recognized standards. The tolerances shall

also be related to the buckling analysis referred to in 6.4.15.2.3.1 and

6.4.15.3.3.2.

16.4.3 Secondary barriers

During construction the regulations for testing and inspection of secondary barriers

shall be approved or accepted by the Administration (see also 6.4.4.5 and 6.4.4.6).

16.4.4 Membrane tanks

The quality assurance/quality control (QA/QC) program shall ensure the continued

conformity of the weld procedure qualification, design details, materials,

construction, inspection and production testing of components. These standards and

procedures shall be developed during the prototype testing programme.

16.5 Testing

16.5.1 Testing and inspections during construction

16.5.1.1 All liquefied gas fuel tanks and process pressure vessels shall

be subjected to hydrostatic or hydro-pneumatic pressure testing in accordance with

16.5.2 to 16.5.5, as applicable for the tank type.

16.5.1.2 All tanks shall be subject to a tightness test which may be

performed in combination with the pressure test referred to in 16.5.1.1.

16.5.1.3 The gas tightness of the fuel containment system with reference

to 6.3.3 shall be tested.

16.5.1.4 Regulations with respect to inspection of secondary barriers

shall be decided by the Administration in each case, taking into account the

accessibility of the barrier (see also 6.4.4).

16.5.1.5 The Administration may require that for ships fitted with novel

type B independent tanks, or tanks designed according to 6.4.16 at least one

prototype tank and its support shall be instrumented with strain gauges or other

suitable equipment to confirm stress levels during the testing required in 16.5.1.1.

Similar instrumentation may be required for type C independent tanks, depending on

their configuration and on the arrangement of their supports and attachments.

16.5.1.6 The overall performance of the fuel containment system shall be

verified for compliance with the design parameters during the first LNG bunkering,

when steady thermal conditions of the liquefied gas fuel are reached, in accordance

with the requirements of the Administration. Records of the performance of the

components and equipment, essential to verify the design parameters, shall be

maintained on board and be available to the Administration.

16.5.1.7 The fuel containment system shall be inspected for cold spots

during or immediately following the first LNG bunkering, when steady thermal

conditions are reached. Inspection of the integrity of thermal insulation surfaces

that cannot be visually checked shall be carried out in accordance with the

requirements of the Administration.

16.5.1.8 Heating arrangements, if fitted in accordance with 6.4.13.1.1.3

and 6.4.13.1.1.4, shall be tested for required heat output and heat

distribution.

16.5.2 Type A independent tanks

All type A independent tanks shall be subjected to a hydrostatic or

hydro-pneumatic pressure testing. This test shall be performed such that the

stresses approximate, as far as practicable, the design stresses, and that the

pressure at the top of the tank corresponds at least to the MARVS. When a

hydropneumatic test is performed, the conditions shall simulate, as far as

practicable, the design loading of the tank and of its support structure including

dynamic components, while avoiding stress levels that could cause permanent

deformation.

16.5.3 Type B independent tanks

Type B independent tanks shall be subjected to a hydrostatic or

hydro-pneumatic pressure testing as follows:

-

.1 The test shall be performed as required in 16.5.2 for type A independent

tanks.

-

.2 In addition, the maximum primary membrane stress or maximum bending stress

in primary members under test conditions shall not exceed 90% of the yield

strength of the material (as fabricated) at the test temperature. To ensure

that this condition is satisfied, when calculations indicate that this

stress exceeds 75% of the yield strength the test of the first of a series

of identical tanks shall be monitored by the use of strain gauges or other

suitable equipment.

16.5.4 Type C independent tanks and other pressure vessels

16.5.4.1 Each pressure vessel shall be subjected to a hydrostatic test

at a pressure measured at the top of the tanks, of not less than 1.5 P0.

In no case during the pressure test shall the calculated primary membrane stress at

any point exceed 90% of the yield strength of the material at the test temperature.

To ensure that this condition is satisfied where calculations indicate that this

stress will exceed 0.75 times the yield strength, the test of the first of a series

of identical tanks shall be monitored by the use of strain gauges or other suitable

equipment in pressure vessels other than simple cylindrical and spherical pressure

vessels.

16.5.4.2 The temperature of the water used for the test shall be at

least 30°C above the nil-ductility transition temperature of the material, as

fabricated.

16.5.4.3 The pressure shall be held for 2 hours per 25 mm of thickness,

but in no case less than 2 hours.

16.5.4.4 Where necessary for liquefied gas fuel pressure vessels, a

hydro-pneumatic test may be carried out under the conditions prescribed in 16.5.4.1

to 16.5.4.3.

16.5.4.5 Special consideration may be given to the testing of tanks in which higher

allowable stresses are used, depending on service temperature. However, regulation

in 16.5.4.1 shall be fully complied with.

16.5.4.6 After completion and assembly, each pressure vessel and its related fittings

shall be subjected to an adequate tightness test, which may be performed in

combination with the pressure testing referred to in 16.5.4.1 or 16.5.4.4 as

applicable.

16.5.4.7 Pneumatic testing of pressure vessels other than liquefied gas fuel tanks

shall be considered on an individual case basis. Such testing shall only be

permitted for those vessels designed or supported such that they cannot be safely

filled with water, or for those vessels that cannot be dried and are to be used in a

service where traces of the testing medium cannot be tolerated.

16.5.5 Membrane tanks

16.5.5.1 Design development testing

16.5.5.1.1 The design development testing required in 6.4.15.4.1.2 shall include a

series of analytical and physical models of both the primary and secondary barriers,

including corners and joints, tested to verify that they will withstand the expected

combined strains due to static, dynamic and thermal loads at all filling levels.

This will culminate in the construction of a prototype scaled model of the complete

liquefied gas fuel containment system. Testing conditions considered in the

analytical and physical model shall represent the most extreme service conditions

the liquefied gas fuel containment system will be likely to encounter over its life.

Proposed acceptance criteria for periodic testing of secondary barriers required in

6.4.4 may be based on the results of testing carried out on the prototype scaled

model.

16.5.5.1.2 The fatigue performance of the membrane materials and representative

welded or bonded joints in the membranes shall be determined by tests. The ultimate

strength and fatigue performance of arrangements for securing the thermal insulation

system to the hull structure shall be determined by analyses or tests.

16.5.5.2 Testing

-

.1 In ships fitted with membrane liquefied gas fuel containment systems, all

tanks and other spaces that may normally contain liquid and are adjacent to

the hull structure supporting the membrane, shall be hydrostatically tested.

-

.2 All hold structures supporting the membrane shall be tested for tightness

before installation of the liquefied gas fuel containment system.

-

.3 Pipe tunnels and other compartments that do not normally contain liquid

need not be hydrostatically tested.

16.6 Welding, post-weld heat

treatment and non-destructive testing

16.6.1 General

Welding shall be carried out in accordance with 16.3.

16.6.2 Post-weld heat treatment

Post-weld heat treatment shall be required for all butt welds of pipes

made with carbon, carbon-manganese and low alloy steels. The Administration may

waive the regulations for thermal stress relieving of pipes with wall thickness less

than 10 mm in relation to the design temperature and pressure of the piping system

concerned.

16.6.3 Non-destructive testing

In addition to normal controls before and during the welding, and to the visual

inspection of the finished welds, as necessary for proving that the welding has been

carried out correctly and according to the regulations in this paragraph, the

following tests shall be required:

-

.1 100% radiographic or ultrasonic inspection of butt-welded joints for

piping systems with;

- .1 design temperatures colder than minus 10°C; or

- .2 design pressure greater than 1.0 MPa; or

- .3 gas supply pipes in ESD protected machinery spaces; or

- .4 inside diameters of more than 75 mm; or

- .5 wall thicknesses greater than 10 mm.

-

.2 When such butt welded joints of piping sections are made by automatic

welding procedures approved by the Administration, then a progressive

reduction in the extent of radiographic or ultrasonic inspection can be

agreed, but in no case to less than 10% of each joint. If defects are

revealed the extent of examination shall be increased to 100% and shall

include inspection of previously accepted welds. This approval can only be

granted if well-documented quality assurance procedures and records are

available to assess the ability of the manufacturer to produce satisfactory

welds consistently.

-

.3 The radiographic or ultrasonic inspection regulation may be reduced to 10%

for butt-welded joints in the outer pipe of double-walled fuel piping.

-

.4 For other butt-welded joints of pipes not covered by 16.6.3.1 and

16.6.3.3, spot radiographic or ultrasonic inspection or other

non-destructive tests shall be carried out depending upon service, position

and materials. In general, at least 10% of butt-welded joints of pipes shall

be subjected to radiographic or ultrasonic inspection.

16.7 Testing regulations

16.7.1 Type testing of piping components

Valves

Each type of piping component intended to be used at a working

temperature below minus 55°C shall be subject to the following type tests:

-

.1 Each size and type of valve shall be subjected to seat tightness testing

over the full range of operating pressures and temperatures, at intervals,

up to the rated design pressure of the valve. Allowable leakage rates shall

be to the requirements of the Administration During the testing satisfactory

operation of the valve shall be verified.

-

.2 The flow or capacity shall be certified to a recognized standard for each

size and type of valve.

-

.3 Pressurized components shall be pressure tested to at least 1.5 times the

design pressure.

-

.4 For emergency shutdown valves, with materials having melting temperatures

lower than 925°C, the type testing shall include a fire test to a standard

at least equivalent to those acceptable to the Organization.footnote

16.7.2 Expansion bellows

The following type tests shall be performed on each type of expansion

bellows intended for use on fuel piping outside the fuel tank as found acceptable in

7.3.6.4.3.1. and .3 and where required by the Administration, on those installed

within the fuel tanks:

-

.1 Elements of the bellows, not pre-compressed, but axially restrained shall

be pressure tested at not less than five times the design pressure without

bursting. The duration of the test shall not be less than five minutes.

-

.2 A pressure test shall be performed on a type expansion joint, complete

with all the accessories such as flanges, stays and articulations, at the

minimum design temperature and twice the design pressure at the extreme

displacement conditions recommended by the manufacturer without permanent

deformation.

-

.3 A cyclic test (thermal movements) shall be performed on a complete

expansion joint, which shall withstand at least as many cycles under the

conditions of pressure, temperature, axial movement, rotational movement and

transverse movement as it will encounter in actual service. Testing at

ambient temperature is permitted when this testing is at least as severe as

testing at the service temperature.

-

.4 A cyclic fatigue test (ship deformation, ship accelerations and pipe

vibrations) shall be performed on a complete expansion joint, without

internal pressure, by simulating the bellows movement corresponding to a

compensated pipe length, for at least 2,000,000 cycles at a frequency not

higher than 5 Hz. This test is only required when, due to the piping

arrangement, ship deformation loads are actually experienced.

16.7.3 System testing regulations

16.7.3.1 The regulations for testing in this section apply to fuel

piping inside and outside the fuel tanks. However, relaxation from these regulations

for piping inside fuel tanks and open ended piping may be accepted by the

Administration.

16.7.3.2 After assembly, all fuel piping shall be subjected to a strength

test with a suitable fluid. The test pressure shall be at least 1.5 times the design

pressure for liquid lines and 1.5 times the maximum system working pressure for

vapour lines. When piping systems or parts of systems are completely manufactured

and equipped with all fittings, the test may be conducted prior to installation on

board the ship. Joints welded on board shall be tested to at least 1.5 times the

design pressure.

16.7.3.3 After assembly on board, the fuel piping system shall be

subjected to a leak test using air, or other suitable medium to a pressure depending

on the leak detection method applied.

16.7.3.4 In double wall fuel piping systems the outer pipe or duct shall

also be pressure tested to show that it can withstand the expected maximum pressure

at pipe rupture.

16.7.3.5 All piping systems, including valves, fittings and associated

equipment for handling fuel or vapours, shall be tested under normal operating

conditions not later than at the first bunkering operation, in accordance with the

requirements of the Administration.

16.7.3.6 Emergency shutdown valves in liquefied gas piping systems shall close fully

and smoothly within 30 s of actuation. Information about the closure time of the

valves and their operating characteristics shall be available on board, and the

closing time shall be verifiable and repeatable.

16.7.3.7 The closing time of the valve referred to in 8.5.8 and 15.4.2.2 (i.e. time

from shutdown signal initiation to complete valve closure) shall not be greater

than:

- where:

- U = ullage volume at operating signal level (m3);

- BR = maximum bunkering rate agreed between ship and shore facility

(m3/h); or

- 5 seconds, whichever is the least.

The bunkering rate shall be adjusted to limit surge pressure on valve closure to an

acceptable level, taking into account the bunkering hose or arm, the ship and the

shore piping systems, where relevant.