2.1 PARAGRAPH 1.3

Interpretation

A "combined chemical/oil tanker complying with the provisions of the

IBC

Code" is a tanker that holds both a valid IOPP certificate as a tanker

and a valid certificate of fitness for the carriage of dangerous chemicals in bulk,

i.e. a tanker that is certified to carry both oil cargoes under MARPOL Annex I and Chemical cargoes in chapter

17 of the IBC Code either as full or part cargoes. The Technical

provisions should be applied to ballast tanks of combined chemical/oil tankers

complying with the provisions of the IBC

Code.

2.2 PARAGRAPH 1.4

Interpretation

1 In the context of the above requirement, the deviation should be applied only to

distances between integrated permanent means of access that are the subject of

paragraph 2.1.2 of table 1.

2 Deviations should not be applied to the distances governing the installation of

under-deck longitudinal walkways and dimensions that determine whether permanent

access is required or not, such as height of the spaces and height to elements of

the structure (e.g. cross-ties).

2.3 PARAGRAPH 3.1

Interpretation

The permanent means of access to a space can be credited for the permanent means of

access for inspection.

Technical background

The Technical provisions specify means of access to a space and to hull structure for

carrying out overall and close-up surveys and inspections. Requirements of means of

access to hull structure may not always be suitable for access to a space. However,

if the means of access to a space can also be used for the intended surveys and

inspections such means of access can be credited for the means of access for use for

surveys and inspections.

2.4 PARAGRAPH 3.3

Interpretation

1 Sloping structures are structures that are sloped by 5 or more degrees from

horizontal plane when a ship is in an upright position at even-keel.

2 Guard rails should be fitted on the open side and should be at least 1,000 mm in

height. For stand-alone passageways guard rails should be fitted on both sides of

these structures. Guardrail stanchions are to be attached to the permanent means of

access. The distance between the passageway and the intermediate bar and the

distance between the intermediate bar and the top rail should not be more than 500

mm.

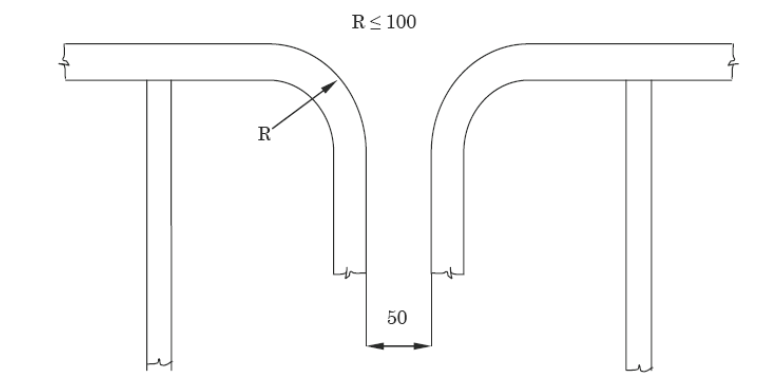

3 Discontinuous top handrails are allowed, provided the gap does not exceed 50 mm.

The same maximum gap is to be considered between the top handrail and other

structural members (i.e. bulkhead, web frame, etc.). The maximum distance between

the adjacent stanchions across the handrail gaps is to be 350 mm where the top and

mid handrails are not connected together and 550 mm when they are connected

together. The maximum distance between the stanchion and other structural members is

not to exceed 200 mm where the top and mid handrails are not connected together and

300 mm when they are connected together. When the top and mid handrails are

connected by a bent rail, the outside radius of the bent part is not to exceed 100

mm (see figure below).

4 Non-skid construction is such that the surface on which personnel walks provides

sufficient friction to the sole of boots even if the surface is wet and covered with

thin sediment.

5 "Substantial construction" is taken to refer to the as-designed strength as well as

the residual strength during the service life of the vessel. Durability of

passageways together with guard rails should be ensured by the initial corrosion

protection and inspection and maintenance during services.

6 For guard rails, use of alternative materials such as GRP should be subject to

compatibility with the liquid carried in the tank. Non-fire resistant materials

should not be used for means of access to a space with a view to securing an escape

route at a high temperature.

7 Requirements for resting platforms placed between ladders should be equivalent to

those applicable to elevated passageways.

Reference

Paragraph 10 of the annex to MSC/Circ.686/Rev.1.

2.5 PARAGRAPH 3.4

Interpretation

Where the vertical manhole is at a height of more than 600 mm above the walking

level, it should be demonstrated that an injured person can be easily evacuated.

2.6 PARAGRAPH 3.5

Interpretation

Means of access to ballast tanks, cargo tanks and spaces other than fore peak

tanks:

For oil tankers:

1 Tanks and subdivisions of tanks having a length of 35 m or more with two access

hatchways:

-

Second access hatchway:

.1 A vertical ladder may be used. In such a case where the

vertical distance is more than 6 m, vertical ladders should comprise one or

more ladder-linking platforms spaced not more than 6 m apart vertically and

displaced to one side of the ladder.

The uppermost section of the vertical ladder, measured clear of

the overhead obstructions in the way of the tank entrance, should not be

less than 2.5 m but not exceed 3.0 m and should comprise a ladder-linking

platform which should be displaced to one side of a vertical ladder.

However, the vertical distance of the uppermost section of the vertical

ladder may be reduced to 1.6 m, measured clear of the overhead obstructions

in the way of the tank entrance, if the ladder lands on a longitudinal or

athwartship permanent means of access fitted within that range. Adjacent

sections of the ladder should be laterally offset from each other by at

least the width of the ladder (see paragraph 20 of MSC/Circ.686/Rev.1 and

refer to the interpretation of paragraphs 3.13.2 and 3.13.6 of the Technical

provisions (resolution MSC.158(78))); or

-

.2 Where an inclined ladder or combination of ladders is used

for access to the space, the uppermost section of the ladder, measured clear

of the overhead obstructions in the way of the tank entrance, should be

vertical for not less than 2.5 m but not exceed 3.0 m and should comprise a

landing platform continuing with an inclined ladder. However, the vertical

distance of the uppermost section of the vertical ladder may be reduced to

1.6 m, measured clear of the overhead obstructions in the way of the tank

entrance, if the ladder lands on a longitudinal or athwartship permanent

means of access fitted within that range. The flights of the inclined

ladders are normally to be not more than 6 m in vertical height. The

lowermost section of the ladders may be vertical for the vertical distance

not exceeding 2.5 m.

2 Tanks less than 35 m in length and served by one access hatchway: an inclined

ladder or combination of ladders should be used to the space as specified in 1.2

above.

3 In spaces of less than 2.5 m in width the access to the space may be by

means of vertical ladders that comprise one or more ladder-linking platforms spaced

not more than 6 m apart vertically and displaced to one side of the ladder. The

uppermost section of the vertical ladder, measured clear of the overhead

obstructions in the way of the tank entrance, should not be less than 2.5 m but not

exceed 3.0 m and should comprise a ladder-linking platform which should be displaced

to one side of a vertical ladder. However, the vertical distance of the uppermost

section of the vertical ladder may be reduced to 1.6 m, measured clear of the

overhead obstructions in the way of the tank entrance, if the ladder lands on a

longitudinal or athwartship permanent means of access fitted within that range.

Adjacent sections of the ladder should be laterally offset from each other by at

least the width of the ladder (see paragraph 20 of MSC/Circ.686/Rev.1 and refer to

the interpretation of paragraphs 3.13.2 and 3.13.6 of the Technical provisions

(resolution MSC.158(78))).

4 Access from the deck to a double-bottom space may be by means of vertical ladders

through a trunk. The vertical distance from deck to a resting platform, between

resting platforms, or a resting platform and the tank bottom should not be more than

6 m, unless otherwise approved by the Administration.

Means of access for inspection of the vertical structure of oil tankers:

Vertical ladders provided for means of access to the space may be used for access for

inspection of the vertical structure.

Unless stated otherwise in table 1 of the Technical provisions, vertical

ladders that are fitted on vertical structures for inspection should comprise one or

more ladder-linking platforms spaced not more than 6 m apart vertically and

displaced to one side of the ladder. Adjacent sections of ladder should be laterally

offset from each other by at least the width of the ladder (see paragraph 20 of

MSC/Circ.686/Rev.1 and refer to the interpretation of paragraphs 3.13.2 and 3.13.6

of the Technical provisions (resolution MSC.158(78))).

Obstruction distances

The minimum distance between the inclined ladder face and obstructions, i.e. 750 mm

and, in the way of openings, 600 mm specified in paragraph 3.5 of the Technical

provisions, should be measured perpendicular to the face of the ladder.

Technical background

It is common practice to use a vertical ladder from the deck to the first landing to

clear overhead obstructions before continuing to an inclined ladder or a vertical

ladder displaced to one side of the first vertical ladder.

Reference

For vertical ladders: paragraph 20 of the annex to MSC/Circ.686/Rev.1.

2.7 PARAGRAPH 3.6

Interpretation

1 The vertical height of handrails should not be less than 890 mm from the centre of

the step and two course handrails need only be provided where the gap between the

stringer and the top handrail is greater than 500 mm.

2 The requirement of two square bars for treads specified in paragraph 3.6 of the

Technical provisions is based upon the specification of the construction of ladders

in paragraph 3(e) of annex 1 to resolution A.272(VIII), which addresses inclined

ladders. Paragraph 3.4 of the Technical Provisions allows for single rungs fitted to

vertical surfaces, which is considered a safe grip. For vertical ladders, when steel

is used, the rungs should be formed of single square bars of not less than 22 mm by

22 mm for the sake of safe grip.

3 The width of inclined ladders for access to a cargo hold should be at least 450 mm

to comply with the Australian AMSA Marine Orders part 32, appendix 17.

4 The width of inclined ladders other than an access to a cargo hold should be not

less than 400 mm.

5 The minimum width of vertical ladders should be 350 mm and the vertical distance

between the rungs should be equal and should be between 250 mm and 350 mm.

6 A minimum climbing clearance in width should be 600 mm other than the ladders

placed between the hold frames.

7 The vertical ladders should be secured at intervals not exceeding 2.5 m apart to

prevent vibration.

Technical background

1 Paragraph 3.6 of the Technical provisions is a continuation of paragraph 3.5 of the

Technical Provisions, which addresses inclined ladders. Interpretations for vertical

ladders are needed based upon the current standards of IMO, AMSA or the industry.

2 Interpretations 2 and 5 address vertical ladders based upon the current standards.

3 Double square bars for treads become too large for a grip for vertical ladders and

single rungs facilitate a safe grip.

4 Interpretation 7 is introduced consistently with the requirement and the

interpretation of paragraph 3.4 of the Technical provisions.

Reference

1 Annex 1 to resolution A.272(VIII).

2 Australian AMSA Marine Orders part 32, appendix 17.

3 ILO Code of Practice Safety and health in dock work – section

3.6, Access to ship's hold.

2.8 PARAGRAPH 3.9.6

Interpretation

A mechanical device such as hooks for securing at the upper end of a ladder should be

considered as an appropriate securing device if a movement fore/aft and sideways can

be prevented at the upper end of the ladder.

Technical background

Innovative design should be accepted if it fits the functional requirement with due

consideration for safe use.

2.10 PARAGRAPH 3.13.1

Interpretation

1 Either a vertical or an inclined ladder or a combination of them may be used for

access to a cargo hold where the vertical distance is 6 m or less from the deck to

the bottom of the cargo hold.

2 Deck is defined as "weather deck".

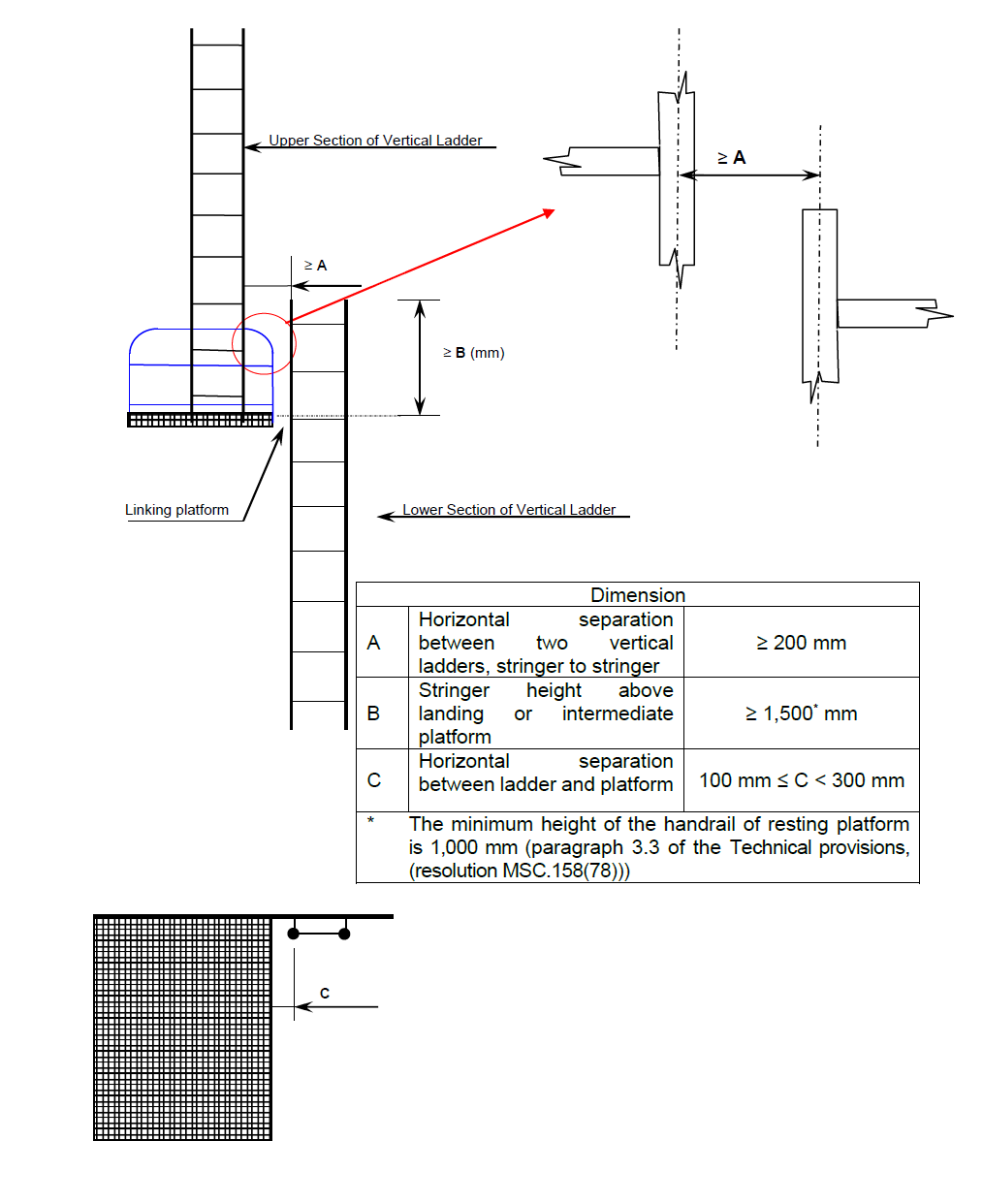

2.11 PARAGRAPHS 3.13.2 AND 3.13.6

Adjacent sections of vertical ladder should be installed so that the

following provisions are complied with:

-

- the minimum "lateral offset" between two adjacent sections

of vertical ladder, is the distance between the sections, upper and

lower, so that the adjacent stringers are spaced of at least 200 mm,

measured from half thickness of each stringer;

-

- adjacent sections of vertical ladder should be installed

so that the upper end of the lower section is vertically overlapped, in

respect to the lower end of the upper section, to a height of 1,500 mm

in order to permit a safe transfer between ladders; and

-

- no section of the access ladder should be terminated

directly or partly above an access opening.

Figure "A"

Vertical Ladder – Ladder through the linking platform

Figure "B"

Vertical Ladder – Side mount

2.12 TABLE 1 – MEANS OF ACCESS FOR BALLAST AND CARGO TANKS OF OIL TANKERS,

PARAGRAPH 1.1

Interpretation

1 Sub-paragraphs .1 to .3 define access to under-deck structures, access

to the uppermost sections of transverse webs and connection between these

structures.

2 Sub-paragraphs .4 to .6 define access to vertical structures only and

are linked to the presence of transverse webs on longitudinal bulkheads.

3 If there are no under-deck structures (deck longitudinals and deck

transverses) but there are vertical structures in the cargo tank supporting

transverse and longitudinal bulkheads, access in accordance with sub-paragraphs .1

to .6 should be provided for inspection of the upper parts of vertical structure on

transverse and longitudinal bulkheads.

4 If there is no structure in the cargo tank, section 1.1 of table 1 should not be

applied.

5 Section 1 of table 1 should also be applied to void spaces in the

cargo area, comparable in volume to spaces covered by SOLAS regulation II-1/3-6, except those spaces

covered by section 2.

6 The vertical distance below the overhead structure should be measured from the

underside of the main deck plating to the top of the platform of the means of access

at a given location.

7 The height of the tank should be measured at each tank. For a tank the height of

which varies at different bays, item 1.1 should be applied to such bays of a tank

that have a height of 6 m and over.

Technical background

Interpretation 7, if the height of the tank is increasing along the length of a ship,

the permanent means of access should be provided locally where the height is above 6

m.

Reference

Paragraph 10 of the annex to MSC/Circ.686/Rev.1.

2.13 TABLE 1 – MEANS OF ACCESS FOR BALLAST AND CARGO TANKS OF OIL TANKERS,

PARAGRAPH 1.1.2

Interpretation

There is a need to provide a continuous longitudinal permanent means of access when

the deck longitudinals and deck transverses are fitted on deck but supporting

brackets are fitted under the deck.

2.14 TABLE 1 – MEANS OF ACCESS FOR BALLAST AND CARGO TANKS OF OIL TANKERS,

PARAGRAPH 1.1.3

Interpretation

Means of access to tanks may be used for access to the permanent means of access for

inspection.

Technical background

As a matter of principle, in such a case where the means of access can be utilized

for the purpose of accessing structural members for inspection there is no need of

duplicated installation of the means of access.

2.15 TABLE 1 – MEANS OF ACCESS FOR BALLAST AND CARGO TANKS OF OIL TANKERS,

PARAGRAPH 1.1.4

Interpretation

The permanent fittings required to serve alternative means of access such as wire

lift platform, that should be used by crew and surveyors for inspection should

provide at least an equal level of safety as the permanent means of access stated by

the same paragraph. These means of access should be carried on board the ship and be

readily available for use without filling of water in the tank. Therefore, rafting

should not be acceptable under this provision. Alternative means of access should be

part of the Ship Structure Access Manual which should be approved on behalf of the

flag State. For water ballast tanks of 5 m or more in width, such as on an ore

carrier, side shell plating should be considered in the same way as "longitudinal

bulkhead".

2.16 TABLE 1 – MEANS OF ACCESS FOR BALLAST AND CARGO TANKS OF OIL TANKERS,

PARAGRAPH 2.1

Interpretation

Section 2 of table 1 should also be applied to wing tanks designed as void spaces.

Paragraph 2.1.1 represents requirements for access to under-deck structures, while

paragraph 2.1.2 is a requirement for access for survey and inspection of vertical

structures on longitudinal bulkheads (transverse webs).

Technical background

SOLAS regulation II-1/3-6.2.1 requires each

space to be provided with means of access. Though void spaces are not addressed in

the technical provisions contained in resolution MSC.158(78), it is arguable whether means of

access are not required in void spaces. Means of access or portable means of access

are necessary arrangements to facilitate inspection of the structural condition of

the space and the boundary structure. Therefore, the requirements of section 2 of

table 1 should be applied to double-hull spaces even when designed as void

spaces.

2.17 TABLE 1 – MEANS OF ACCESS FOR BALLAST AND CARGO TANKS OF OIL TANKERS,

PARAGRAPH 2.1.1

Interpretation

1 For a tank, the vertical distance between horizontal upper stringer and deck head

of which varies at different sections, paragraph 2.1.1 should be applied to such

sections that fall under the criteria.

2 The continuous permanent means of access may be a wide longitudinal, which provides

access to critical details on the opposite side by means of platforms as necessary

on web frames. In case the vertical opening of the web frame is located in the way

of the open part between the wide longitudinal and the longitudinal on the opposite

side, platforms should be provided on both sides of the web frames to allow safe

passage through the web frame.

3 Where two access hatches are required by SOLAS regulation II-1/3-6.3.2, access ladders

at each end of the tank should lead to the deck.

Technical background

Interpretation 1: The interpretation of varied tank height in column 1 of table 1 is

applied to the vertical distance between horizontal upper stringer and deck head for

consistency.

2.18 TABLE 1 – MEANS OF ACCESS FOR BALLAST AND CARGO TANKS OF OIL TANKERS,

PARAGRAPH 2.1.2

Interpretation

The continuous permanent means of access may be a wide longitudinal, which provides

access to critical details on the opposite side by means of platforms as necessary

on web frames. In case the vertical opening of the web is located in the way of the

open part between the wide longitudinal and the longitudinal on the opposite side,

platforms should be provided on both sides of the web to allow safe passage through

the web. A "reasonable deviation", as noted in paragraph 1.4 of the Technical

provisions, of not more than 10% may be applied where the permanent means of access

is integral with the structure itself.

2.19 TABLE 1 – MEANS OF ACCESS FOR BALLAST AND CARGO TANKS OF OIL TANKERS,

PARAGRAPH 2.2

Interpretation

1 Permanent means of access between the longitudinal continuous permanent means of

access and the bottom of the space should be provided.

2 The height of a bilge hopper tank located outside of the parallel part of the ship

should be taken as the maximum of the clear vertical distance measured from the

bottom plating to the hopper plating of the tank.

3 The foremost and aftmost bilge hopper ballast tanks with raised bottom, of which

the height is 6 m and over, a combination of transverse and vertical means of access

to the upper knuckle point for each transverse web, should be accepted in place of

the longitudinal permanent means of access.

Technical background

Interpretation 2: The bilge hopper tanks at fore and aft of cargo area narrow due to

raised bottom plating and the actual vertical distance from the bottom of the tank

to hopper plating of the tank is more appropriate to judge if a portable means of

access could be utilized for the purpose.

Interpretation 3: In the foremost or aftmost bilge hopper tanks where the vertical

distance is 6 m or over but installation of longitudinal permanent means of access

is not practicable, permanent means of access of combination of transverse and

vertical ladders provides an alternative means of access to the upper knuckle

point.

2.20 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 1.1

Interpretation

1 Means of access should be provided to the cross-deck structures of the foremost and

aftermost part of each cargo hold.

2 Interconnected means of access under the cross deck for access to three locations

at both sides and in the vicinity of the centreline should be acceptable as the

three means of access.

3 Permanent means of access fitted at three separate locations accessible

independently, one at each side and one in the vicinity of the centreline, should be

acceptable.

4 Special attention should be paid to the structural strength where any access

opening is provided in the main deck or cross deck.

5 The requirements for a bulk carrier cross-deck structure should also be considered

applicable to ore carriers.

Technical background

Pragmatic arrangements of the means of access are provided.

2.21 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 1.3

Interpretation

Particular attention should be paid to preserve the structural strength in way of

access opening provided in the main deck or cross deck.

2.22 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 1.4

Interpretation

"Full upper stools" are understood to be stools with a full extension between topside

tanks and between hatch end beams.

2.23 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 1.5

Interpretation

1 The movable means of access to the under-deck structure of cross deck need not

necessarily be carried on board the ship. It should be sufficient if it is made

available when needed.

2 The requirements for a bulk carrier cross-deck structure should also be considered

applicable to ore carriers.

2.24 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 1.6

Interpretation

The maximum vertical distance of the rungs of vertical ladders for

access to hold frames should be 350 mm. If a safety harness is to be used, means

should be provided for connecting the safety harness in suitable places in a

practical way.

Technical background

The maximum vertical distance of the rungs of 350 mm is applied with a

view to reducing trapping cargoes.

2.25 TABLE 2 – MEANS OF ACCESS FOR

BULK CARRIERS, PARAGRAPH 1.7

Interpretation

Portable, movable or alternative means of access should also be applied

to corrugated bulkheads.

2.26 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 1.8

Interpretation

Readily available means able to be transported to location in cargo hold and safely

erected by ships' crew.

2.27 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 2.3

Interpretation

If the longitudinal structures on the sloping plate are fitted outside of the tank, a

means of access should be provided.

2.28 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 2.5

Interpretation

1 The height of a bilge hopper tank located outside of the parallel part of the

vessel should be taken as the maximum of the clear vertical height measured from the

bottom plating to the hopper plating of the tank.

2 It should be demonstrated that portable means for inspection can be deployed and

made readily available in the areas where needed.

2.29 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 2.5.2

Interpretation

A wide longitudinal frame of at least 600 mm clear width may be used for the purpose

of the longitudinal continuous permanent means of access. The foremost and aftermost

bilge hopper ballast tanks with raised bottom, of which the height is 6 m and over,

a combination of transverse and vertical means of access to the sloping plate of

hopper tank connection with side shell plating for each transverse web can be

accepted in place of the longitudinal permanent means of access.

2.30 TABLE 2 – MEANS OF ACCESS FOR BULK CARRIERS, PARAGRAPH 2.6

Interpretation

The height of web frame rings should be measured in way of side shell and tank

base.

Technical background

In the bilge hopper tank the sloping plating is above the opening, while

the movement of the surveyor is along the bottom of the tank. Therefore, the

measurement of 1 m should be taken from the bottom of the tank.