6.1.1 The longitudinally continuous upper deck of a bulk carrier suffers

hull girder stress. The longitudinal bending causes an axial force

on the upper deck that may cause cracking of the deck plate at the

locations where the stress is concentrated.

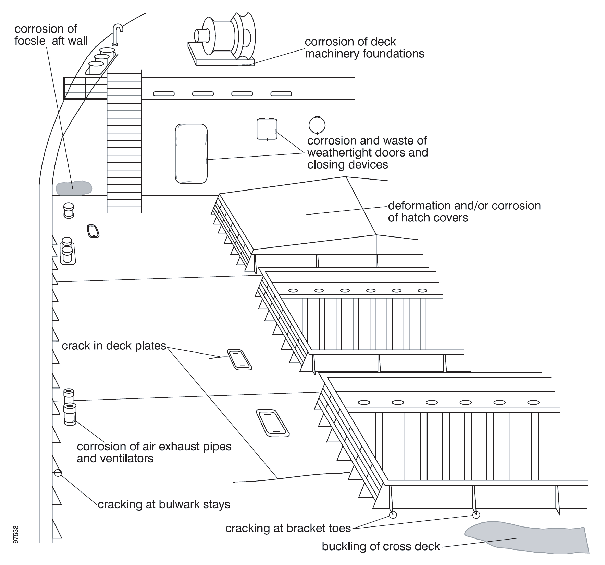

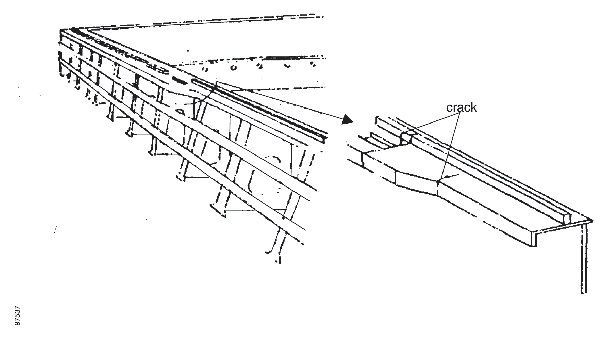

Figure 4 Check points on the upper deck

6.1.2 Bulk carriers have cargo hatchways for the

convenience of cargo handling facilities. These hatchways reduce the

ship's torsional strength and invite concentrated stress at the hatchway

corners which may be evident by cracking of the deck plates in these

areas.

6.1.3 Cross deck strips come under stress by transverse

bending. The transverse bulkheads provide transverse strength to a

bulk carrier and the cross deck strips provide the strength to withstand

the resultant axial forces in transverse direction.

Deformation

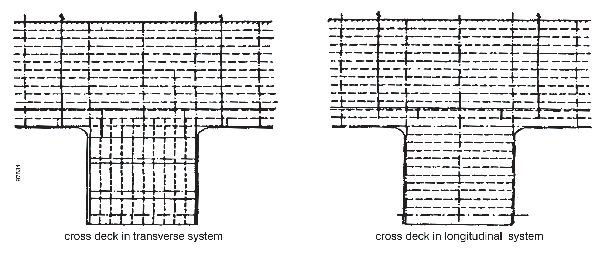

Figure 5 Comparison of stiffening systems for cross deck

6.1.4 Generally, longitudinal beams are arranged

under the longitudinally continuous upper deck outboard of the side

lines of the cargo hatchways. This is called the longitudinal system.

When the deck beams for cross deck strips are also arranged in this

manner, buckling of the cross deck strips may take place due to insufficient

strength against the axial forces acting on them in transverse direction.

The transverse system is the preferred method of construction for

cross deck members. Particular attention should be given to buckling

of the main deck on those ships where the cross deck strips are arranged

in the longitudinal system.

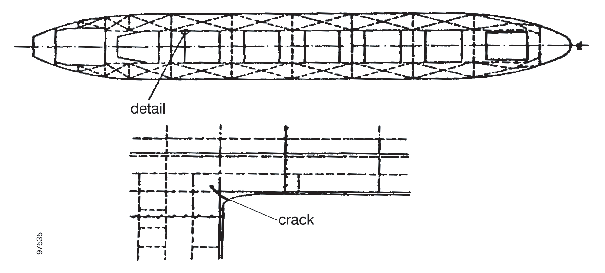

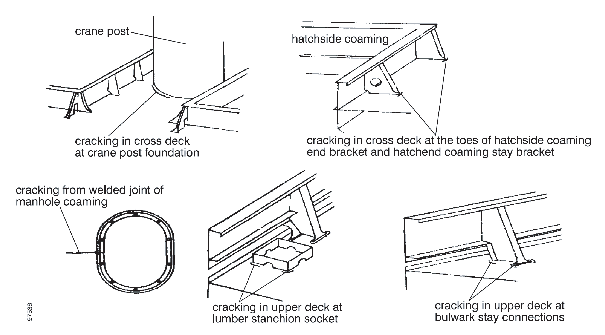

6.1.5 There are various types of cracking in the

upper deck. Those propagating from the cargo hatchways are generally

considered serious to the ship's safety:

-

.1

Hatchway

comers

The large cargo hatchway openings reduce the torsional strength

of the hull and invite stress concentration at their corners on the

upper deck. In this regard, upper deck plating at hatchway corners

is one of the focal points for cracking. Particular attention should

be paid to these areas during inspection.

-

.2

Upper

deck plating at deck fittings

Various metal fittings are welded to the upper deck plating.

These installations may cause stress concentrations at the welded

joints or have defects in the welds. Deck platings in vicinity of

manholes, hatchside coaming end brackets, bulwark stays, crane post

foundations and deck houses, etc. are to be carefully watched for

cracking.

-

.3

Hatch

coamings

Hatch coamings are subjected to hull girder stress. Although

they are not critical longitudinal strength members, they should be

watched carefully to ensure that these cracks do not spread. Cracking

may be initiated at defects in welded joints and metal fittings to

the coamings that will invite stress concentration. Such cracking

is considered serious to ship's safety because it may be the initiation

of a fracture of a large scale.

Figure 6 Cracking at hatchway

Figure 7 Various crackings in upper deck plating

Figure 8 Cracking in hatch coaming

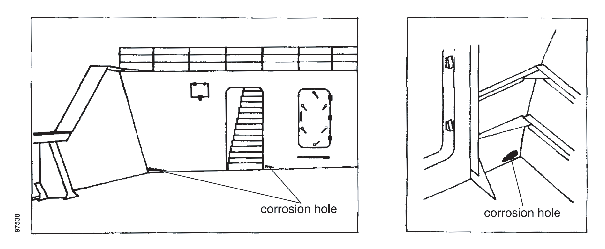

6.1.6 Thinner steel structures on deck, such as

cross deck strips, hatch coamings, hatch covers, etc., are easily

corroded and often holed. The best way to deter corrosion is to keep

the structure well coated and painted. The parts most liable to corrosion

in the upper deck area are as follows:

-

.1

Cross

deck strips

The thickness of cross deck plating between hatchways is designed

about a half of that of main strength deck plating because it is not

a longitudinal strength member. However, cross deck strips provide

an important part in the transverse strength of the ship, and corrosion

and waste of the cross deck plating may be considered serious to the

ship's soundness.

-

.2

Hatch covers

The thickness of hatch covers is approximately the same as that

of cross decks. Holes in hatch covers caused by corrosion lead to

water ingress in cargo holds which may lead to shifting of cargo and/or

problems with the stability of the ship.

-

.3

Hatch coamings

When steam pipes are arranged beside hatchside coamings, the

corrosion progress of the coaming is very rapid. Corrosion holes of

the coaming plates lead to the same problems as those associated with

hatch cover corrosion.

-

.4

Weathertight doors, small hatches and

wall ventilator covers

Not only covers, door plates and coamings but also hinges, gaskets

and clips are to be always kept in good condition.

-

.5

Standing pipes on deck

Vent and sounding pipes from water ballast or fuel oil tanks

and ventilation pipes for closed spaces under the upper deck are liable

to corrosion. If these pieces become holed, seawater comes directly

into the tanks or cargo holds and may cause contamination of fuel

oil, cargo damage, shifting of cargo, and/or stability problems.

-

.6

Forecastle

aft wall

The bilges in forecastle space may cause corrosion of the bulkhead

where it meets the deck. In flush decked bulk carriers, the boatswain

store aft wall may be corroded in the same manner. Large bulk carriers

generally do not have forecastles and have their boatswain stores

down below the upper deck in fore peak spaces. Bilges left in such

spaces also cause corrosion of the aft end bulkheads which separates

boatswain store and No. 1 cargo hold. Such wastage may lead to water

ingress, cargo damage, cargo shifting and/or stability problems.

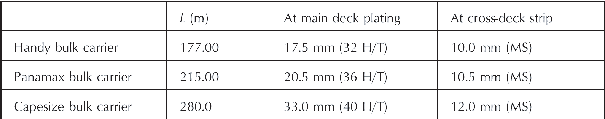

Figure 9 Examples of comparison of thickness of main deck and cross deck

Figure 10 Forecastle end bulkhead