6.1 Goal

The goal of this chapter is to provide that gas storage is adequate so as to minimize

the risk to personnel, the ship and the environment to a level that is equivalent to

a conventional oil fuelled ship.

6.2 Functional requirements

This chapter relates to functional requirements in 3.2.1, 3.2.2, 3.2.5

and 3.2.8 to 3.2.17. In particular the following apply:

-

.1 the fuel containment system shall be so designed that a leak from the tank

or its connections does not endanger the ship, persons on board or the

environment. Potential dangers to be avoided include:

-

.1 exposure of ship materials to temperatures below acceptable

limits;

-

.2 flammable fuels spreading to locations with ignition sources;

-

.3 toxicity potential and risk of oxygen deficiency due to fuels and

inert gases;

-

.4 restriction of access to muster stations, escape routes and

life-saving appliances (LSA); and

-

.5 reduction in availability of LSA.

-

.2 the pressure and temperature in the fuel tank shall be kept within the

design limits of the containment system and possible carriage requirements

of the fuel;

-

.3 the fuel containment arrangement shall be so designed that safety actions

after any gas leakage do not lead to an unacceptable loss of power; and

-

.4 if portable tanks are used for fuel storage, the design of the fuel

containment system shall be equivalent to permanent installed tanks as

described in this chapter.

6.3 Regulations – General

6.3.1 Natural gas in a liquid state may be stored with a maximum

allowable relief valve setting (MARVS) of up to 1.0 MPa.

6.3.2 The Maximum Allowable Working Pressure (MAWP) of the gas fuel tank

shall not exceed 90% of the Maximum Allowable Relief Valve Setting (MARVS).

6.3.3 A fuel containment system located below deck shall be gas tight

towards adjacent spaces.

6.3.4 All tank connections, fittings, flanges and tank valves must be

enclosed in gas tight tank connection spaces, unless the tank connections are on

open deck. The space shall be able to safely contain leakage from the tank in case

of leakage from the tank connections.

6.3.5 Pipe connections to the fuel storage tank shall be mounted above

the highest liquid level in the tanks, except for fuel storage tanks of type C.

Connections below the highest liquid level may however also be accepted for other

tank types after special consideration by the Administration.

6.3.6 Piping between the tank and the first valve which release liquid in

case of pipe failure shall have equivalent safety as the type C tank, with dynamic

stress not exceeding the values given in 6.4.15.3.1.2.

6.3.7 The material of the bulkheads of the tank connection space shall

have a design temperature corresponding with the lowest temperature it can be

subject to in a probable maximum leakage scenario. The tank connection space shall

be designed to withstand the maximum pressure build up during such a leakage.

Alternatively, pressure relief venting to a safe location (mast) can be

provided.

6.3.8 The probable maximum leakage into the tank connection space shall

be determined based on detail design, detection and shutdown systems.

6.3.9 If piping is connected below the liquid level of

the tank it has to be protected by a secondary barrier up to the first valve.

6.3.10 If liquefied gas fuel storage tanks are

located on open deck the ship steel shall be protected from potential leakages from

tank connections and other sources of leakage by use of drip trays. The material is

to have a design temperature corresponding to the temperature of the fuel carried at

atmospheric pressure. The normal operation pressure of the tanks shall be taken into

consideration for protecting the steel structure of the ship.

6.3.11 Means shall be provided whereby liquefied gas

in the storage tanks can be safely emptied.

6.3.12 It shall be possible to empty, purge and vent

fuel storage tanks with fuel piping systems. Instructions for carrying out these

procedures must be available on board. Inerting shall be performed with an inert gas

prior to venting with dry air to avoid an explosion hazardous atmosphere in tanks

and fuel pipes. See detailed regulations in 6.10.

6.4 Regulations for liquefied gas

fuel containment

6.4.1 General

6.4.1.1 The risk assessment required in 4.2 shall include evaluation of

the ship's liquefied gas fuel containment system, and may lead to additional safety

measures for integration into the overall vessel design.

6.4.1.2 The design life of fixed liquefied gas fuel containment system

shall not be less than the design life of the ship or 20 years, whichever is

greater.

6.4.1.3 The design life of portable tanks shall not be less than 20

years.

6.4.1.4 Liquefied gas fuel containment systems shall be designed in

accordance with North Atlantic environmental conditions and relevant long-term sea

state scatter diagrams for unrestricted navigation. Less demanding environmental

conditions, consistent with the expected usage, may be accepted by the

Administration for liquefied gas fuel containment systems used exclusively for

restricted navigation. More demanding environmental conditions may be required for

liquefied gas fuel containment systems operated in conditions more severe than the

North Atlantic environment. footnote,footnote

6.4.1.5 Liquefied gas fuel containment systems shall be designed with

suitable safety margins:

- .1 to withstand, in the intact condition, the environmental

conditions anticipated for the liquefied gas fuel containment system's

design life and the loading conditions appropriate for them, which shall

include full homogeneous and partial load conditions and partial filling to

any intermediate levels; and

- .2 being appropriate for uncertainties in loads, structural

modelling, fatigue, corrosion, thermal effects, material variability, aging

and construction tolerances.

6.4.1.6 The liquefied gas fuel containment system structural strength

shall be assessed against failure modes, including but not limited to plastic

deformation, buckling and fatigue. The specific design conditions that shall be

considered for the design of each liquefied gas fuel containment system are given in

6.4.15. There are three main categories of design conditions:

-

.1 Ultimate Design Conditions – The liquefied gas fuel containment system

structure and its structural components shall withstand loads liable to

occur during its construction, testing and anticipated use in service,

without loss of structural integrity. The design shall take into account

proper combinations of the following loads:

-

.1 internal pressure;

-

.2 external pressure;

-

.3 dynamic loads due to the motion of the ship in all loading

conditions;

-

.4 thermal loads;

-

.5 sloshing loads;

-

.6 loads corresponding to ship deflections;

-

.7 tank and liquefied gas fuel weight with the corresponding reaction

in way of supports;

-

.8 insulation weight;

-

.9 loads in way of towers and other attachments; and

-

.10 test loads.

-

.2 Fatigue Design Conditions – The liquefied gas fuel containment system

structure and its structural components shall not fail under accumulated

cyclic loading.

- .3 Accidental Design Conditions – The liquefied gas fuel containment

system shall meet each of the following accident design conditions (accidental

or abnormal events), addressed in this Code:

-

.1 Collision – The liquefied gas fuel containment system shall

withstand the collision loads specified in 6.4.9.5.1 without

deformation of the supports or the tank structure in way of the

supports likely to endanger the tank and its supporting

structure.

-

.2 Fire – The liquefied gas fuel containment systems shall sustain

without rupture the rise in internal pressure specified in 6.7.3.1

under the fire scenarios envisaged therein.

-

.3 Flooded compartment causing buoyancy on tank – the anti-flotation

arrangements shall sustain the upward force, specified in 6.4.9.5.2

and there shall be no endangering plastic deformation to the hull.

Plastic deformation may occur in the fuel containment system

provided it does not endanger the safe evacuation of the ship.

6.4.1.7 Measures shall be applied to ensure that scantlings required

meet the structural strength provisions and are maintained throughout the design

life. Measures may include, but are not limited to, material selection, coatings,

corrosion additions, cathodic protection and inerting.

6.4.1.8 An inspection/survey plan for the liquefied gas fuel containment

system shall be developed and approved by the Administration. The inspection/survey

plan shall identify aspects to be examined and/or validated during surveys

throughout the liquefied gas fuel containment system's life and, in particular, any

necessary in-service survey, maintenance and testing that was assumed when selecting

liquefied gas fuel containment system design parameters. The inspection/survey plan

may include specific critical locations as per 6.4.12.2.8 or 6.4.12.2.9.

6.4.1.9 Liquefied gas fuel containment systems shall be designed,

constructed and equipped to provide adequate means of access to areas that need

inspection as specified in the inspection/survey plan. Liquefied gas fuel

containment systems, including all associated internal equipment shall be designed

and built to ensure safety during operations, inspection and maintenance.

6.4.2 Liquefied gas fuel containment safety principles

6.4.2.1 The containment systems shall be provided with a complete

secondary liquid-tight barrier capable of safely containing all potential leakages

through the primary barrier and, in conjunction with the thermal insulation system,

of preventing lowering of the temperature of the ship structure to an unsafe

level.

6.4.2.2 The size and configuration or arrangement of the secondary

barrier may be reduced or omitted where an equivalent level of safety can be

demonstrated in accordance with 6.4.2.3 to 6.4.2.5 as applicable.

6.4.2.3 Liquefied gas fuel containment systems for which the probability

for structural failures to develop into a critical state has been determined to be

extremely low but where the possibility of leakages through the primary barrier

cannot be excluded, shall be equipped with a partial secondary barrier and small

leak protection system capable of safely handling and disposing of the leakages (a

critical state means that the crack develops into unstable condition).

The arrangements shall comply with the following:

- .1 failure developments that can be reliably detected before

reaching a critical state (e.g. by gas detection or inspection) shall have a

sufficiently long development time for remedial actions to be taken;

and

- .2 failure developments that cannot be safely detected before

reaching a critical state shall have a predicted development time that is

much longer than the expected lifetime of the tank.

6.4.2.4 No secondary barrier is required for liquefied gas fuel

containment systems, e.g. type C independent tanks, where the probability for

structural failures and leakages through the primary barrier is extremely low and

can be neglected.

6.4.2.5 For independent tanks requiring full or partial secondary barrier,

means for safely disposing of leakages from the tank shall be arranged.

6.4.3 Secondary barriers in relation to tank types

Secondary barriers in relation to the tank types defined in 6.4.15 shall

be provided in accordance with the following table.

| Basic tank type

|

Secondary barrier requirements

|

| Membrane

|

Complete secondary barrier

|

|

|

|

| Independent

|

|

| Type A

|

Complete secondary barrier

|

| Type B

|

Partial secondary barrier

|

| Type C

|

No secondary barrier required

|

6.4.4 Design of secondary barriers

The design of the secondary barrier, including spray shield if fitted,

shall be such that:

-

.1 it is capable of containing any envisaged leakage of liquefied gas fuel

for a period of 15 days unless different criteria apply for particular

voyages, taking into account the load spectrum referred to in

6.4.12.2.6;

-

.2 physical, mechanical or operational events within the liquefied gas fuel

tank that could cause failure of the primary barrier shall not impair the

due function of the secondary barrier, or vice versa;

-

.3 failure of a support or an attachment to the hull structure will not lead

to loss of liquid tightness of both the primary and secondary barriers;

-

.4 it is capable of being periodically checked for its effectiveness by means

of a visual inspection or other suitable means acceptable to the

Administration;

- .

5 the methods required in 6.4.4.4 shall be approved by the

Administration and shall include, as a minimum:

-

.1 details on the size of defect acceptable and the location within

the secondary barrier, before its liquid tight effectiveness is

compromised;

-

.2 accuracy and range of values of the proposed method for detecting

defects in .1 above;

-

.3 scaling factors to be used in determining the acceptance criteria

if full-scale model testing is not undertaken; and

-

.4 effects of thermal and mechanical cyclic loading on the

effectiveness of the proposed test.

-

.6 the secondary barrier shall fulfil its functional requirements at a static

angle of heel of 30°.

6.4.5 Partial secondary barriers and primary barrier small leak

protection system

6.4.5.1 Partial secondary barriers as permitted in 6.4.2.3 shall be used

with a small leak protection system and meet all the regulations in 6.4.4.

The small leak protection system shall include means to detect a leak in

the primary barrier, provision such as a spray shield to deflect any liquefied gas

fuel down into the partial secondary barrier, and means to dispose of the liquid,

which may be by natural evaporation.

6.4.5.2 The capacity of the partial secondary barrier shall be

determined, based on the liquefied gas fuel leakage corresponding to the extent of

failure resulting from the load spectrum referred to in 6.4.12.2.6, after the

initial detection of a primary leak. Due account may be taken of liquid evaporation,

rate of leakage, pumping capacity and other relevant factors.

6.4.5.3 The required liquid leakage detection may be by means of liquid

sensors, or by an effective use of pressure, temperature or gas detection systems,

or any combination thereof.

6.4.5.4 For independent tanks for which the geometry does not present

obvious locations for leakage to collect, the partial secondary barrier shall also

fulfil its functional requirements at a nominal static angle of trim.

6.4.6 Supporting arrangements

6.4.6.1 The liquefied gas fuel tanks shall be supported by the hull in a

manner that prevents bodily movement of the tank under the static and dynamic loads

defined in 6.4.9.2 to 6.4.9.5, where applicable, while allowing contraction and

expansion of the tank under temperature variations and hull deflections without

undue stressing of the tank and the hull.

6.4.6.2 Anti-flotation arrangements shall be provided for independent

tanks and capable of withstanding the loads defined in 6.4.9.5.2 without plastic

deformation likely to endanger the hull structure.

6.4.6.3 Supports and supporting arrangements shall withstand the loads

defined in 6.4.9.3.3.8 and 6.4.9.5, but these loads need not be combined with each

other or with wave-induced loads.

6.4.7 Associated structure and equipment

6.4.7.1 Liquefied gas fuel containment systems shall be designed for the

loads imposed by associated structure and equipment. This includes pump towers,

liquefied gas fuel domes, liquefied gas fuel pumps and piping, stripping pumps and

piping, nitrogen piping, access hatches, ladders, piping penetrations, liquid level

gauges, independent level alarm gauges, spray nozzles, and instrumentation systems

(such as pressure, temperature and strain gauges).

6.4.8 Thermal insulation

6.4.8.1 Thermal insulation shall be provided as required to protect the

hull from temperatures below those allowable (see 6.4.13.1.1) and limit the heat

flux into the tank to the levels that can be maintained by the pressure and

temperature control system applied in 6.9.

6.4.9 Design loads

6.4.9.1 General

6.4.9.1.1 This section defines the design loads that shall be considered

with regard to regulations in 6.4.10 to 6.4.12. This includes load categories

(permanent, functional, environmental and accidental) and the description of the

loads.

6.4.9.1.2 The extent to which these loads shall be considered depends on

the type of tank, and is more fully detailed in the following paragraphs.

6.4.9.1.3 Tanks, together with their supporting structure and other

fixtures, shall be designed taking into account relevant combinations of the loads

described below.

6.4.9.2 Permanent loads

6.4.9.2.1 Gravity loads

The weight of tank, thermal insulation, loads caused by towers and other

attachments shall be considered.

6.4.9.2.2 Permanent external loads

Gravity loads of structures and equipment acting externally on the tank

shall be considered.

6.4.9.3 Functional loads

6.4.9.3.1 Loads arising from the operational use of the tank system

shall be classified as functional loads.

6.4.9.3.2 All functional loads that are essential for ensuring the

integrity of the tank system, during all design conditions, shall be considered.

6.4.9.3.3 As a minimum, the effects from the following criteria, as

applicable, shall be considered when establishing functional loads:

- (a) internal pressure

- (b) external pressure

- (c) thermally induced loads

- (d) vibration

- (e) interaction loads

- (f) loads associated with construction and installation

- (g) test loads

- (h) static heel loads

- (i) weight of liquefied gas fuel

- (j) sloshing

- (k) wind impact, wave impacts and green sea effect for tanks

installed on open deck.

6.4.9.3.3.1 Internal pressure

- .1 In all cases, including 6.4.9.3.3.1.2, P0 shall not

be less than MARVS.

- .2 For liquefied gas fuel tanks where there is no temperature

control and where the pressure of the liquefied gas fuel is dictated only by the

ambient temperature, P0 shall not be less than the gauge vapour

pressure of the liquefied gas fuel at a temperature of 45°C except as

follows:

- .1 Lower values of ambient temperature may be accepted by

the Administration for ships operating in restricted areas. Conversely,

higher values of ambient temperature may be required.

- .2 For ships on voyages of restricted duration,

P0 may be calculated based on the actual pressure

rise during the voyage and account may be taken of any thermal

insulation of the tank.

- .3 Subject to special consideration by the Administration and to the

limitations given in 6.4.15 for the various tank types, a vapour pressure

Ph higher than P0 may be accepted for site

specific conditions (harbour or other locations), where dynamic loads are

reduced.

- .4 Pressure used for determining the internal pressure shall be:

- .1 (Pgd)max is the associated

liquid pressure determined using the maximum design accelerations.

- .2 (Pgd site)max is the associated

liquid pressure determined using site specific accelerations.

- .3 Peq should be the greater of

Peq1 and Peq2 calculated as

follows:

- Peq1 = P0 +

(Pgd)max (MPa),

- Peq2 = Ph +

(Pgd site)max (MPa).

- .5 The internal liquid pressures are those created by the resulting

acceleration of the centre of gravity of the liquefied gas fuel due to the

motions of the ship referred to in 6.4.9.4.1.1. The value of internal liquid

pressure Pgd resulting from combined effects of gravity and

dynamic accelerations shall be calculated as follows:

-

Pgd = αβZβ(ρ/(1.02 X

105)) (MPa)

-

where:

-

αβ = dimensionless acceleration (i.e.

relative to the acceleration of gravity), resulting from

gravitational and dynamic loads, in an arbitrary direction

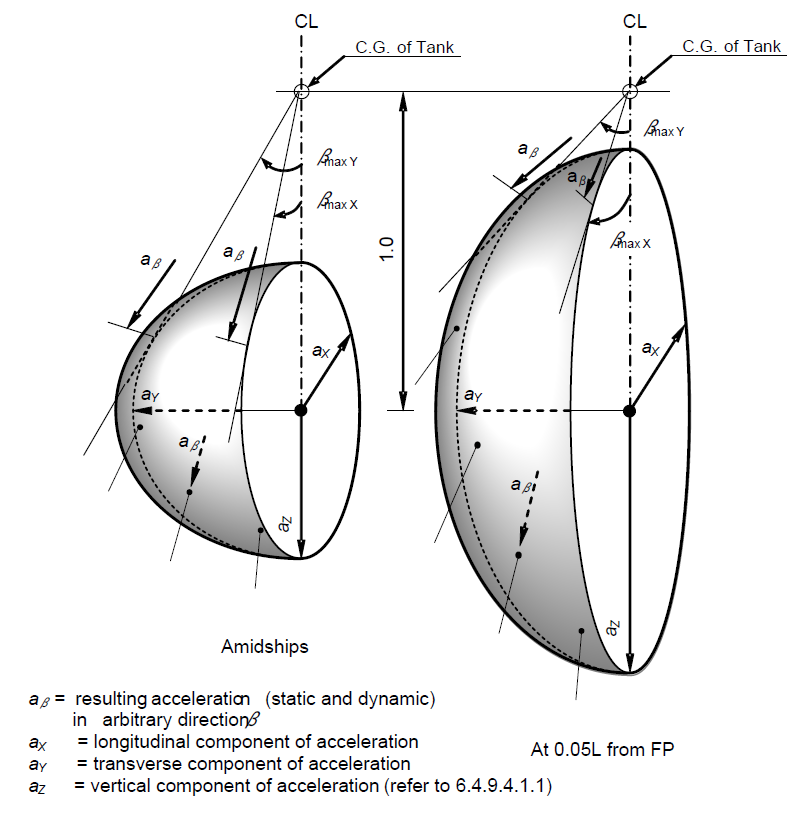

β; (see figure 6.4.1).

For large tanks, an acceleration ellipsoid,

taking account of transverse vertical and longitudinal

accelerations, should be used.

-

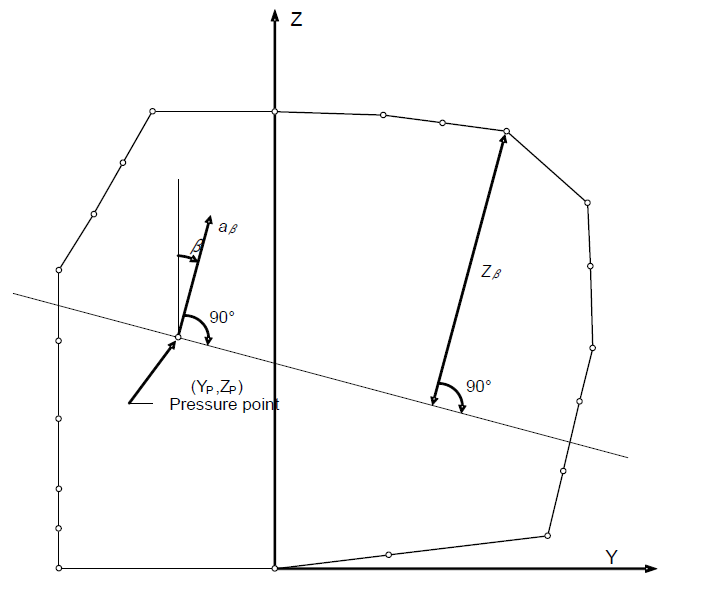

Zβ = largest liquid height (m)

above the point where the pressure is to be determined

measured from the tank shell in the β direction (see

figure 6.4.2).

Tank domes considered to be

part of the accepted total tank volume shall be taken into

account when determining Zβ unless the

total volume of tank domes Vd does not

exceed the following value:

where:

-

ρ = maximum liquefied gas fuel density

(kg/m3) at the design temperature.

-

The direction that gives the maximum value

(Pgd)max or (Pgd

site)max shall be considered. Where

acceleration components in three directions need to be considered,

an ellipsoid shall be used instead of the ellipse in figure 6.4.1.

The above formula applies only to full tanks.

Figure 6.4.1 –

Acceleration ellipsoid

Figure 6.4.2 –

Determination of internal pressure heads

6.4.9.3.3.2 External pressure

External design pressure loads shall be based on the difference between

the minimum internal pressure and the maximum external pressure to which any portion

of the tank may be simultaneously subjected.

6.4.9.3.3.3 Thermally induced loads

6.4.9.3.3.3.1 Transient thermally induced loads during cooling down

periods shall be considered for tanks intended for liquefied gas fuel temperatures

below minus 55°C.

6.4.9.3.3.3.2 Stationary thermally induced loads shall be considered for

liquefied gas fuel containment systems where the design supporting arrangements or

attachments and operating temperature may give rise to significant thermal stresses

(see paragraph 6.9.2).

6.4.9.3.3.4 Vibration

The potentially damaging effects of vibration on the liquefied gas fuel

containment system shall be considered.

6.4.9.3.3.5 Interaction loads

The static component of loads resulting from interaction between

liquefied gas fuel containment system and the hull structure, as well as loads from

associated structure and equipment, shall be considered.

6.4.9.3.3.6 Loads associated with construction and installation

Loads or conditions associated with construction and installation shall

be considered, e.g. lifting.

6.4.9.3.3.7 Test loads

Account shall be taken of the loads corresponding to the testing of the

liquefied gas fuel containment system referred to in 16.5.

6.4.9.3.3.8 Static heel loads

Loads corresponding to the most unfavourable static heel angle within

the range 0° to 30°shall be considered.

6.4.9.3.3.9 Other loads

Any other loads not specifically addressed, which could have an effect

on the liquefied gas fuel containment system, shall be taken into account.

6.4.9.4 Environmental loads

6.4.9.4.1 Environmental loads are defined as those loads on the

liquefied gas fuel containment system that are caused by the surrounding environment

and that are not otherwise classified as a permanent, functional or accidental

load.

6.4.9.4.1.1 Loads due to ship motion

The determination of dynamic loads shall take into account the long-term

distribution of ship motion in irregular seas, which the ship will experience during

its operating life. Account may be taken of the reduction in dynamic loads due to

necessary speed reduction and variation of heading. The ship's motion shall include

surge, sway, heave, roll, pitch and yaw. The accelerations acting on tanks shall be

estimated at their centre of gravity and include the following components:

- .1 vertical acceleration: motion accelerations of heave, pitch and,

possibly roll (normal to the ship base);

- .2 transverse acceleration: motion accelerations of sway, yaw and

roll and gravity component of roll; and

- .3 longitudinal acceleration: motion accelerations of surge and

pitch and gravity component of pitch.

Methods to predict accelerations due to ship motion shall be proposed and

approved by the Administrationfootnote.

Ships for restricted service may be given special consideration.

6.4.9.4.1.2 Dynamic interaction loads

Account shall be taken of the dynamic component of loads resulting from

interaction between liquefied gas fuel containment systems and the hull structure,

including loads from associated structures and equipment.

6.4.9.4.1.3 Sloshing loads

The sloshing loads on a liquefied gas fuel containment system and

internal components shall be evaluated for the full range of intended filling

levels.

6.4.9.4.1.4 Snow and ice loads

Snow and icing shall be considered, if relevant.

6.4.9.4.1.5 Loads due to navigation in ice

Loads due to navigation in ice shall be considered for ships intended for

such service.

6.4.9.4.1.6 Green sea loading

Account shall be taken to loads due to water on deck.

6.4.9.4.1.7 Wind loads

Account shall be taken to wind generated loads as relevant.

6.4.9.5 Accidental loads

Accidental loads are defined as loads that are imposed on a liquefied

gas fuel containment system and it's supporting arrangements under abnormal and

unplanned conditions.

6.4.9.5.1 Collision load

The collision load shall be determined based on the fuel containment

system under fully loaded condition with an inertial force corresponding to "a" in

the table below in forward direction and "a/2" in the aft direction, where "g" is

gravitational acceleration.

| Ship length (L)

|

Design acceleration (a)

|

| L > 100 m

|

0,5 g

|

| 60 < L ≤ 100 m

|

|

| L ≤ 60 m

|

2g

|

Special consideration should be given to ships with Froude number (Fn)

> 0,4.

6.4.9.5.2 Loads due to flooding on ship

For independent tanks, loads caused by the buoyancy of a fully submerged

empty tank shall be considered in the design of anti-flotation chocks and the

supporting structure in both the adjacent hull and tank structure.

6.4.10 Structural integrity

6.4.10.1 General

6.4.10.1.1 The structural design shall ensure that tanks have an

adequate capacity to sustain all relevant loads with an adequate margin of safety.

This shall take into account the possibility of plastic deformation, buckling,

fatigue and loss of liquid and gas tightness.

6.4.10.1.2 The structural integrity of liquefied gas fuel containment

systems can be demonstrated by compliance with 6.4.15, as appropriate for the

liquefied gas fuel containment system type.

6.4.10.1.3 For other liquefied gas fuel containment system types, that

are of novel design or differ significantly from those covered by 6.4.15, the

structural integrity shall be demonstrated by compliance with 6.4.16.

6.4.11 Structural analysis

6.4.11.1 Analysis

6.4.11.1.1 The design analyses shall be based on accepted principles of

statics, dynamics and strength of materials.

6.4.11.1.2 Simplified methods or simplified analyses may be used to

calculate the load effects, provided that they are conservative. Model tests may be

used in combination with, or instead of, theoretical calculations. In cases where

theoretical methods are inadequate, model or full-scale tests may be required.

6.4.11.1.3 When determining responses to dynamic loads, the dynamic

effect shall be taken into account where it may affect structural integrity.

6.4.11.2 Load scenarios

6.4.11.2.1 For each location or part of the liquefied gas fuel

containment system to be considered and for each possible mode of failure to be

analysed, all relevant combinations of loads that may act simultaneously shall be

considered.

6.4.11.2.2 The most unfavourable scenarios for all relevant phases during

construction, handling, testing and in service conditions shall be considered.

6.4.11.2.3 When the static and dynamic stresses are calculated separately

and unless other methods of calculation are justified, the total stresses shall be

calculated according to:

where:

- σx.st, σy.st, σz.st,

τxy.st, τxz.st and τyz.st

are static stresses; and

- σx.dyn, σy.dyn, σz.dyn,

τxy.dyn, τxz.dyn and τyz.dyn

are dynamic stresses,

each shall be determined separately from acceleration components and

hull strain components due to deflection and torsion.

6.4.12 Design conditions

All relevant failure modes shall be considered in the design for all

relevant load scenarios and design conditions. The design conditions are given in

the earlier part of this chapter, and the load scenarios are covered by

6.4.11.2.

6.4.12.1 Ultimate design condition

6.4.12.1.1 Structural capacity may be determined by testing, or by

analysis, taking into account both the elastic and plastic material properties, by

simplified linear elastic analysis or by the provisions of this Code:

-

.2 Analysis shall be based on characteristic load values as follows:

| Permanent

loads

|

Expected

values

|

| Functional

loads

|

Specified

values

|

| Environmental

loads

|

For wave loads:

most probable largest load encountered during

108 wave encounters.

|

-

.3 For the purpose of ultimate strength assessment the following material

parameters apply:

-

.1 Re = specified minimum yield stress at room

temperature (N/mm2). If the stress-strain curve does not

show a defined yield stress, the 0.2% proof stress applies.

-

.2 Rm = specified minimum tensile strength at room

temperature (N/mm2).

- For welded connections where under-matched welds, i.e. where

the weld metal has lower tensile strength than the parent metal,

are unavoidable, such as in some aluminium alloys, the

respective Re and Rm of the

welds, after any applied heat treatment, shall be used. In such

cases the transverse weld tensile strength shall not be less

than the actual yield strength of the parent metal. If this

cannot be achieved, welded structures made from such materials

shall not be incorporated in liquefied gas fuel containment

systems.

-

The above properties shall correspond to the minimum specified

mechanical properties of the material, including the weld metal in

the as fabricated condition. Subject to special consideration by the

Administration, account may be taken of the enhanced yield stress

and tensile strength at low temperature.

-

.4 The equivalent stress σc (von Mises, Huber) shall be

determined by:

-

.5 Allowable stresses for materials other than those covered by 7.4 shall be

subject to approval by the Administration in each case.

6.4.12.2 Fatigue Design Condition

-

.1 The fatigue design condition is the design condition with respect to

accumulated cyclic loading.

-

.2 Where a fatigue analysis is required the cumulative effect of the fatigue

load shall comply with:

-

where:

-

ni = number of stress cycles at each stress level

during the life of the tank;

-

Ni = number of cycles to fracture for the

respective stress level according to the Wohler (S-N)

curve;

-

nLoading = number of loading and unloading cycles

during the life of the tank not to be less than 1000. Loading and

unloading cycles include a complete pressure and thermal cycle;

-

NLoading = number of cycles to fracture for the

fatigue loads due to loading and unloading; and

-

Cw = maximum allowable cumulative fatigue damage

ratio.

-

The fatigue damage shall be based on the design life of the tank but not less

than 108 wave encounters.

-

.3 Where required, the liquefied gas fuel containment system shall be subject

to fatigue analysis, considering all fatigue loads and their appropriate

combinations for the expected life of the liquefied gas fuel containment

system. Consideration shall be given to various filling conditions.

-

.4 Design S-N curves used in the analysis shall be applicable to the

materials and weldments, construction details, fabrication procedures and

applicable state of the stress envisioned.

The S-N curves shall be based on a 97.6% probability of survival

corresponding to the mean-minus-two-standard-deviation curves of relevant

experimental data up to final failure. Use of S-N curves derived in a

different way requires adjustments to the acceptable Cw values specified in

6.4.12.2.7 to 6.4.12.2.9.

-

.5 Analysis shall be based on characteristic load values as follows:

| Permanent loads

|

Expected

values

|

| Functional

loads

|

Specified values or

specified history

|

| Environmental

loads

|

Expected load history,

but not less than 108 cycles

|

If simplified dynamic loading spectra are used for the estimation

of the fatigue life, those shall be specially considered by the

Administration.

-

.6 Where the size of the secondary barrier is reduced, as is provided for in

6.4.2.3, fracture mechanics analyses of fatigue crack growth shall be

carried out to determine:

- .1 crack propagation paths in the structure, where

necessitated by 6.4.12.2.7 to 6.4.12.2.9, as applicable;

- .2 crack growth rate;

- .3 the time required for a crack to propagate to cause a

leakage from the tank;

- .4 the size and shape of through thickness cracks; and

- .5 the time required for detectable cracks to reach a

critical state after penetration through the thickness.

- The fracture mechanics are in general based on crack growth

data taken as a mean value plus two standard deviations of the test

data. Methods for fatigue crack growth analysis and fracture mechanics

shall be based on recognized standards.

- In analysing crack propagation the largest initial crack not

detectable by the inspection method applied shall be assumed, taking

into account the allowable non-destructive testing and visual inspection

criterion as applicable.

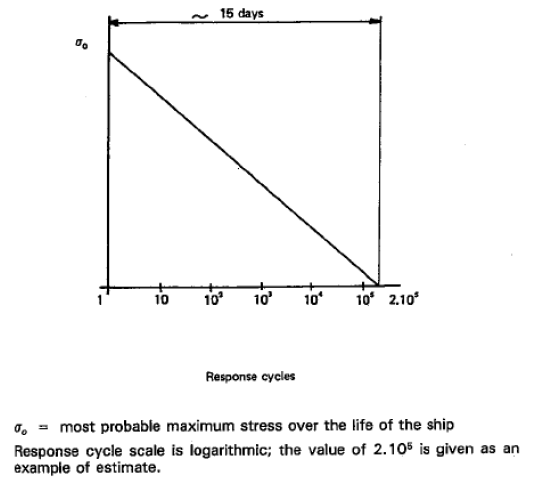

- Crack propagation analysis specified in 6.4.12.2.7 the

simplified load distribution and sequence over a period of 15 days may

be used. Such distributions may be obtained as indicated in figure

6.4.3. Load distribution and sequence for longer periods, such as in

6.4.12.2.8 and 6.4.12.2.9 shall be approved by the Administration.

- The arrangements shall comply with 6.4.12.2.7 to 6.4.12.2.9

as applicable.

-

.7 For failures that can be reliably detected by means of leakage

detection:

- Cw shall be less than or equal to

0.5.

- Predicted remaining failure development time, from the point

of detection of leakage till reaching a critical state, shall not be

less than 15 days unless different regulations apply for ships engaged

in particular voyages.

- .

8 For failures that cannot be detected by leakage but that can

be reliably detected at the time of in-service inspections:

- Cw shall be less than or equal to

0.5.

- Predicted remaining failure development time, from the

largest crack not detectable by in-service inspection methods until

reaching a critical state, shall not be less than three (3) times the

inspection interval.

-

.9 In particular locations of the tank where effective defect or crack

development detection cannot be assured, the following, more stringent,

fatigue acceptance criteria shall be applied as a minimum:

- Cw shall be less than or equal to

0.1.

- Predicted failure development time, from the assumed

initial defect until reaching a critical state, shall not be less than

three (3) times the lifetime of the tank.

Figure 6.4.3 – Simplified load

distribution

6.4.12.3 Accidental design condition

6.4.12.3.1 The accidental design condition is a design condition for

accidental loads with extremely low probability of occurrence.

6.4.12.3.2 Analysis shall be based on the characteristic values as

follows:

| Permanent loads

|

Expected values

|

| Functional loads

|

Specified values

|

| Environmental loads

|

Specified values

|

| Accidental loads

|

Specified values or expected

values

|

Loads mentioned in 6.4.9.3.3.8 and 6.4.9.5 need not be combined with

each other or with wave-induced loads.

6.4.13 Materials and construction

6.4.13.1 Materials

6.4.13.1.1 Materials forming ship structure

6.4.13.1.1.1 To determine the grade of plate and sections used in the

hull structure, a temperature calculation shall be performed for all tank types. The

following assumptions shall be made in this calculation:

- .1 The primary barrier of all tanks shall be assumed to be at the

liquefied gas fuel temperature.

- .2 In addition to .1 above, where a complete or partial secondary

barrier is required it shall be assumed to be at the liquefied gas fuel

temperature at atmospheric pressure for any one tank only.

- .3 For worldwide service, ambient temperatures shall be taken as

5°C for air and 0°C for seawater. Higher values may be accepted for ships

operating in restricted areas and conversely, lower values may be imposed by the

Administration for ships trading to areas where lower temperatures are expected

during the winter months.

- .4 Still air and sea water conditions shall be assumed, i.e. no

adjustment for forced convection.

- .5 Degradation of the thermal insulation properties over the life

of the ship due to factors such as thermal and mechanical ageing, compaction,

ship motions and tank vibrations as defined in 6.4.13.3.6 and 6.4.13.3.7 shall

be assumed.

- .6 The cooling effect of the rising boil-off vapour from the

leaked liquefied gas fuel shall be taken into account where applicable.

- .7 Credit for hull heating may be taken in accordance with

6.4.13.1.1.3, provided the heating arrangements are in compliance with

6.4.13.1.1.4.

- .8 No credit shall be given for any means of heating, except as

described in 6.4.13.1.1.3.

- .9 For members connecting inner and outer hulls, the mean

temperature may be taken for determining the steel grade.

6.4.13.1.1.2 The materials of all hull structures for which the

calculated temperature in the design condition is below 0°C, due to the influence of

liquefied gas fuel temperature, shall be in accordance with table 7.5. This includes

hull structure supporting the liquefied gas fuel tanks, inner bottom plating,

longitudinal bulkhead plating, transverse bulkhead plating, floors, webs, stringers

and all attached stiffening members.

6.4.13.1.1.3 Means of heating structural materials may be used to ensure

that the material temperature does not fall below the minimum allowed for the grade

of material specified in table 7.5. In the calculations required in 6.4.13.1.1.1,

credit for such heating may be taken in accordance with the following

principles:

- .1 for any transverse hull structure;

- .2 for longitudinal hull structure referred to in 6.4.13.1.1.2

where colder ambient temperatures are specified, provided the material remains

suitable for the ambient temperature conditions of plus 5°C for air and 0°C for

seawater with no credit taken in the calculations for heating; and

- .3 as an alternative to 6.4.13.1.1.3.2, for longitudinal bulkhead

between liquefied gas fuel tanks, credit may be taken for heating provided the

material remain suitable for a minimum design temperature of minus 30°C, or a

temperature 30°C lower than that determined by 6.4.13.1.1.1 with the heating

considered, whichever is less. In this case, the ship's longitudinal strength

shall comply with SOLAS regulation II-1/3-1 for both when

those bulkhead(s) are considered effective and not.

6.4.13.1.1.4 The means of heating referred to in 6.4.13.1.1.3 shall

comply with the following:

- .1 the heating system shall be arranged so that, in the event of

failure in any part of the system, standby heating can be maintained equal to no

less than 100% of the theoretical heat requirement;

- .2 the heating system shall be considered as an essential

auxiliary. All electrical components of at least one of the systems provided in

accordance with 6.4.13.1.1.3.1 shall be supplied from the emergency source of

electrical power; and

- .3 the design and construction of the heating system shall be

included in the approval of the containment system by the Administration.

6.4.13.2 Materials of primary and secondary barriers

6.4.13.2.1 Metallic materials used in the construction of primary and

secondary barriers not forming the hull, shall be suitable for the design loads that

they may be subjected to, and be in accordance with table 7.1, 7.2 or 7.3.

6.4.13.2.2 Materials, either non-metallic or metallic but not covered by

tables 7.1, 7.2 and 7.3, used in the primary and secondary barriers may be approved

by the Administration considering the design loads that they may be subjected to,

their properties and their intended use.

6.4.13.2.3 Where non-metallic materials,footnote including composites, are used for or

incorporated in the primary or secondary barriers, they shall be tested for the

following properties, as applicable, to ensure that they are adequate for the

intended service:

- .1 compatibility with the liquefied gas fuels;

- .2 ageing;

- .3 mechanical properties;

- .4 thermal expansion and contraction;

- .5 abrasion;

- .6 cohesion;

- .7 resistance to vibrations;

- .8 resistance to fire and flame spread; and

- .9 resistance to fatigue failure and crack propagation.

6.4.13.2.4 The above properties, where applicable, shall be tested for

the range between the expected maximum temperature in service and 5°C below the

minimum design temperature, but not lower than minus196°C.

6.4.13.2.5 Where non-metallic materials, including composites, are used

for the primary and secondary barriers, the joining processes shall also be tested

as described above.

6.4.13.2.6 Consideration may be given to the use of materials in the

primary and secondary barrier, which are not resistant to fire and flame spread,

provided they are protected by a suitable system such as a permanent inert gas

environment, or are provided with a fire retardant barrier.

6.4.13.3 Thermal insulation and other materials used in liquefied gas

fuel containment systems

6.4.13.3.1 Load-bearing thermal insulation and other materials used in

liquefied gas fuel containment systems shall be suitable for the design loads.

6.4.13.3.2 Thermal insulation and other materials used in liquefied gas

fuel containment systems shall have the following properties, as applicable, to

ensure that they are adequate for the intended service:

- .1 compatibility with the liquefied gas fuels;

- .2 solubility in the liquefied gas fuel;

- .3 absorption of the liquefied gas fuel;

- .4 shrinkage;

- .5 ageing;

- .6 closed cell content;

- .7 density;

- .8 mechanical properties, to the extent that they are subjected to

liquefied gas fuel and other loading effects, thermal expansion and contraction;

- .9 abrasion;

- .10 cohesion;

- .11 thermal conductivity;

- .12 resistance to vibrations;

- .13 resistance to fire and flame spread; and

- .14 resistance to fatigue failure and crack propagation.

6.4.13.3.3 The above properties, where applicable, shall be tested for

the range between the expected maximum temperature in service and 5°C below the

minimum design temperature, but not lower than minus 196°C.

6.4.13.3.4 Due to location or environmental conditions, thermal

insulation materials shall have suitable properties of resistance to fire and flame

spread and shall be adequately protected against penetration of water vapour and

mechanical damage. Where the thermal insulation is located on or above the exposed

deck, and in way of tank cover penetrations, it shall have suitable fire resistance

properties in accordance with a recognized standard or be covered with a material

having low flame spread characteristics and forming an efficient approved vapour

seal.

6.4.13.3.5 Thermal insulation that does not meet recognized standards

for fire resistance may be used in fuel storage hold spaces that are not kept

permanently inerted, provided its surfaces are covered with material with low flame

spread characteristics and that forms an efficient approved vapour seal.

6.4.13.3.6 Testing for thermal conductivity of thermal insulation shall

be carried out on suitably aged samples.

6.4.13.3.7 Where powder or granulated thermal insulation is used,

measures shall be taken to reduce compaction in service and to maintain the required

thermal conductivity and also prevent any undue increase of pressure on the

liquefied gas fuel containment system.

6.4.14 Construction processes

6.4.14.1 Weld joint design

6.4.14.1.1 All welded joints of the shells of independent tanks shall be

of the in-plane butt weld full penetration type. For dome-to-shell connections only,

tee welds of the full penetration type may be used depending on the results of the

tests carried out at the approval of the welding procedure. Except for small

penetrations on domes, nozzle welds are also to be designed with full

penetration.

6.4.14.1.2 Welding joint details for type C independent tanks, and for

the liquid-tight primary barriers of type B independent tanks primarily constructed

of curved surfaces, shall be as follows:

- .1 All longitudinal and circumferential joints shall be of butt

welded, full penetration, double vee or single vee type. Full penetration butt

welds shall be obtained by double welding or by the use of backing rings. If

used, backing rings shall be removed except from very small process pressure

vessels.footnote Other edge preparations may be

permitted, depending on the results of the tests carried out at the approval of

the welding procedure. For connections of tank shell to a longitudinal bulkhead

of type C bilobe tanks, tee welds of the full penetration type may be accepted.

- .2 The bevel preparation of the joints between the tank body and

domes and between domes and relevant fittings shall be designed according to a

standard acceptable to the Administration. All welds connecting nozzles, domes

or other penetrations of the vessel and all welds connecting flanges to the

vessel or nozzles shall be full penetration welds.

6.4.14.2 Design for gluing and other joining processes

6.4.14.2.1 The design of the joint to be glued (or joined by some other

process except welding) shall take account of the strength characteristics of the

joining process.

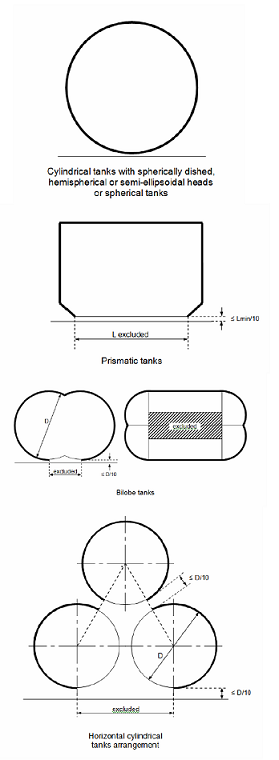

6.4.15 Tank types

6.4.15.1 Type A independent tanks

6.4.15.1.1 Design basis

6.4.15.1.1.1 Type A independent tanks are tanks primarily designed using

classical ship-structural analysis procedures in accordance with the requirements of

the Administration. Where such tanks are primarily constructed of plane surfaces,

the design vapour pressure P0 shall be less than 0.07 MPa.

6.4.15.1.1.2 A complete secondary barrier is required as defined in

6.4.3. The secondary barrier shall be designed in accordance with 6.4.4.

6.4.15.1.2 Structural analysis

6.4.15.1.2.1 A structural analysis shall be performed taking into

account the internal pressure as indicated in 6.4.9.3.3.1, and the interaction loads

with the supporting and keying system as well as a reasonable part of the ship's

hull.

6.4.15.1.2.2 For parts, such as structure in way of supports, not

otherwise covered by the regulations in this Code, stresses shall be determined by

direct calculations, taking into account the loads referred to in 6.4.9.2 to 6.4.9.5

as far as applicable, and the ship deflection in way of supports.

6.4.15.1.2.3 The tanks with supports shall be designed for the

accidental loads specified in 6.4.9.5. These loads need not be combined with each

other or with environmental loads.

6.4.15.1.3 Ultimate design condition

6.4.15.1.3.1 For tanks primarily constructed of plane surfaces, the

nominal membrane stresses for primary and secondary members (stiffeners, web frames,

stringers, girders), when calculated by classical analysis procedures, shall not

exceed the lower of Rm/2.66 or Re/1.33 for nickel steels,

carbon-manganese steels, austenitic steels and aluminium alloys, where Rm

and Re are defined in 6.4.12.1.1.3. However, if detailed calculations are

carried out for the primary members, the equivalent stress σc, as defined in

6.4.12.1.1.4, may be increased over that indicated above to a stress acceptable to

the Administration. Calculations shall take into account the effects of bending,

shear, axial and torsional deformation as well as the hull/liquefied gas fuel tank

interaction forces due to the deflection of the hull structure and liquefied gas

fuel tank bottoms.

6.4.15.1.3.2 Tank boundary scantlings shall meet at least the

requirements of the Administration for deep tanks taking into account the internal

pressure as indicated in 6.4.9.3.3.1 and any corrosion allowance required by

6.4.1.7.

6.4.15.1.3.3 The liquefied gas fuel tank structure shall be reviewed

against potential buckling.

6.4.15.1.4 Accidental design condition

6.4.15.1.4.1 The tanks and the tank supports shall be designed for the

accidental loads and design conditions specified in 6.4.9.5 and 6.4.1.6.3 as

relevant.

6.4.15.1.4.2 When subjected to the accidental loads specified in

6.4.9.5, the stress shall comply with the acceptance criteria specified in

6.4.15.1.3, modified as appropriate taking into account their lower probability of

occurrence.

6.4.15.2 Type B independent tanks

6.4.15.2.1 Design basis

6.4.15.2.1.1 Type B independent tanks are tanks designed using model

tests, refined analytical tools and analysis methods to determine stress levels,

fatigue life and crack propagation characteristics. Where such tanks are primarily

constructed of plane surfaces (prismatic tanks) the design vapour pressure

P0 shall be less than 0.07 MPa.

6.4.15.2.1.2 A partial secondary barrier with a protection system is

required as defined in 6.4.3. The small leak protection system shall be designed

according to 6.4.5.

6.4.15.2.2 Structural analysis

6.4.15.2.2.1 The effects of all dynamic and static loads shall be used

to determine the suitability of the structure with respect to:

- .1 plastic deformation;

- .2 buckling;

- .3 fatigue failure; and

- .4 crack propagation.

Finite element analysis or similar methods and fracture mechanics

analysis or an equivalent approach, shall be carried out.

6.4.15.2.2.2 A three-dimensional analysis shall be carried out to

evaluate the stress levels, including interaction with the ship's hull. The model

for this analysis shall include the liquefied gas fuel tank with its supporting and

keying system, as well as a reasonable part of the hull.

6.4.15.2.2.3 A complete analysis of the particular ship accelerations

and motions in irregular waves, and of the response of the ship and its liquefied

gas fuel tanks to these forces and motions, shall be performed unless the data is

available from similar ships.

6.4.15.2.3 Ultimate design condition

6.4.15.2.3.1 Plastic deformation

For type B independent tanks, primarily constructed of bodies of

revolution, the allowable stresses shall not exceed:

- σm ≤ f

- σL ≤ 1.5f

- σb ≤ 1.5F

- σL + σb ≤ 1.5F

- σm + σb ≤ 1.5F

- σm + σb + σg

≤ 3.0F

- σL + σb + σg

≤ 3.0F

where:

- σm = equivalent primary general membrane

stress;

- σL = equivalent primary local membrane stress;

- σb = equivalent primary bending stress;

- σg = equivalent secondary stress;

- f = the lesser of (Rm / A) or (Re

/ B); and

- F = the lesser of (Rm / C) or (Re

/ D),

with Rmand Re

as defined in 6.4.12.1.1.3. With regard to the stresses σm,

σL ,

σg and σb see also the definition of stress

categories in 6.4.15.2.3.6.

The values A and B shall have at least the following minimum values:

|

|

Nickel steels and carbon manganese

steels

|

Austenitic steel

|

Aluminium alloys

|

| A

|

3

|

3.5

|

4

|

| B

|

2

|

1.6

|

1.5

|

| C

|

3

|

3

|

3

|

| D

|

1.5

|

1.5

|

1.5

|

The above figures may be altered considering the design condition

considered in acceptance with the Administration. For type B independent tanks,

primarily constructed of plane surfaces, the allowable membrane equivalent stresses

applied for finite element analysis shall not exceed:

- .1 for nickel steels and carbon-manganese steels, the lesser of

Rm /2 or Re /1.2;

- .2 for austenitic steels, the lesser of Rm /2.5

or Re /1.2; and

- .3 for aluminium alloys, the lesser of Rm /2.5

or Re /1.2.

The above figures may be amended considering the locality of the stress,

stress analysis methods and design condition considered in acceptance with the

Administration.

The thickness of the skin plate and the size of the stiffener shall not

be less than those required for type A independent tanks.

6.4.15.2.3.2 Buckling

Buckling strength analyses of liquefied gas fuel tanks subject to

external pressure and other loads causing compressive stresses shall be carried out

in accordance with recognized standards. The method shall adequately account for the

difference in theoretical and actual buckling stress as a result of plate edge

misalignment, lack of straightness or flatness, ovality and deviation from true

circular form over a specified arc or chord length, as applicable.

6.4.15.2.3.3 Fatigue design condition

6.4.15.2.3.3.1 Fatigue and crack propagation assessment shall be

performed in accordance with the provisions of 6.4.12.2. The acceptance criteria

shall comply with 6.4.12.2.7, 6.4.12.2.8 or 6.4.12.2.9, depending on the

detectability of the defect.

6.4.15.2.3.3.2 Fatigue analysis shall consider construction tolerances.

6.4.15.2.3.3.3 Where deemed necessary by the Administration, model tests

may be required to determine stress concentration factors and fatigue life of

structural elements.

6.4.15.2.3.4 Accidental design condition

6.4.15.2.3.4.1 The tanks and the tank supports shall be designed for the

accidental loads and design conditions specified in 6.4.9.5 and 6.4.1.6.3, as

relevant.

6.4.15.2.3.4.2 When subjected to the accidental loads specified in

6.4.9.5, the stress shall comply with the acceptance criteria specified in

6.4.15.2.3, modified as appropriate, taking into account their lower probability of

occurrence.

6.4.15.2.3.5 Marking

Any marking of the pressure vessel shall be achieved by a method that

does not cause unacceptable local stress raisers.

6.4.15.2.3.6 Stress categories

For the purpose of stress evaluation, stress categories are defined in

this section as follows:

-

.1 Normal stress is the component of stress normal to the plane of

reference.

-

.2 Membrane stress is the component of normal stress that is uniformly

distributed and equal to the average value of the stress across the

thickness of the section under consideration.

-

.3 Bending stress is the variable stress across the thickness of the

section under consideration, after the subtraction of the membrane stress.

-

.4 Shear stress is the component of the stress acting in the plane of

reference.

-

.5 Primary stress is a stress produced by the imposed loading, which

is necessary to balance the external forces and moments. The basic

characteristic of a primary stress is that it is not self-limiting. Primary

stresses that considerably exceed the yield strength will result in failure

or at least in gross deformations.

-

.6 Primary general membrane stress is a primary membrane stress that

is so distributed in the structure that no redistribution of load occurs as

a result of yielding.

-

.7 Primary local membrane stress arises where a membrane stress

produced by pressure or other mechanical loading and associated with a

primary or a discontinuity effect produces excessive distortion in the

transfer of loads for other portions of the structure. Such a stress is

classified as a primary local membrane stress, although it has some

characteristics of a secondary stress. A stress region may be considered as

local, if:

- where:

-

S1 = distance in the meridional direction over

which the equivalent stress exceeds 1.1f;

-

S2 = distance in the meridional direction to

another region where the limits for primary general membrane stress

are exceeded;

-

R = mean radius of the vessel;

-

t = wall thickness of the vessel at the location where the

primary general membrane stress limit is exceeded; and

-

f = allowable primary general membrane stress.

-

.8 Secondary stress is a normal stress or shear stress developed by

constraints of adjacent parts or by self-constraint of a structure. The

basic characteristic of a secondary stress is that it is self-limiting.

Local yielding and minor distortions can satisfy the conditions that cause

the stress to occur.

6.4.15.3 Type C independent tanks

6.4.15.3.1 Design basis

6.4.15.3.1.1 The design basis for type C independent tanks is based on

pressure vessel criteria modified to include fracture mechanics and crack

propagation criteria. The minimum design pressure defined in 6.4.15.3.1.2 is

intended to ensure that the dynamic stress is sufficiently low so that an initial

surface flaw will not propagate more than half the thickness of the shell during the

lifetime of the tank.

6.4.15.3.1.2 The design vapour pressure shall not be less than:

- P0 = 0.2 +

AC(ρr)1.5 (MPa)

where:

6.4.15.3.2 Shell thickness

6.4.15.3.2.1 In considering the shell thickness the following apply:

- .1 for pressure vessels, the thickness calculated according to

6.4.15.3.2.4 shall be considered as a minimum thickness after forming, without

any negative tolerance;

- .2 for pressure vessels, the minimum thickness of shell and heads

including corrosion allowance, after forming, shall not be less than 5 mm for

carbon manganese steels and nickel steels, 3 mm for austenitic steels or 7 mm

for aluminium alloys; and

- .3 the welded joint efficiency factor to be used in the calculation

according to 6.4.15.3.2.4 shall be 0.95 when the inspection and the

non-destructive testing referred to in 16.3.6.4 are carried out. This figure may

be increased up to 1.0 when account is taken of other considerations, such as

the material used, type of joints, welding procedure and type of loading. For

process pressure vessels the Administration may accept partial non-destructive

examinations, but not less than those of 16.3.6.4, depending on such factors as

the material used, the design temperature, the nil ductility transition

temperature of the material as fabricated and the type of joint and welding

procedure, but in this case an efficiency factor of not more than 0.85 shall be

adopted. For special materials the above-mentioned factors shall be reduced,

depending on the specified mechanical properties of the welded joint.

6.4.15.3.2.2 The design liquid pressure defined in 6.4.9.3.3.1 shall be

taken into account in the internal pressure calculations.

6.4.15.3.2.3 The design external pressure Pe, used for

verifying the buckling of the pressure vessels, shall not be less than that given

by:

Pe = P1 + P2 +

P3 + P4 (MPa)

where:

- P1 = setting value of vacuum relief valves. For

vessels not fitted with vacuum relief valves P1shall be

specially considered, but shall not in general be taken as less than 0.025 MPa.

- P2 = the set pressure of the pressure relief

valves (PRVs) for completely closed spaces containing pressure vessels or parts

of pressure vessels; elsewhere P2= 0.

- P3 = compressive actions in or on the shell due

to the weight and contraction of thermal insulation, weight of shell including

corrosion allowance and other miscellaneous external pressure loads to which the

pressure vessel may be subjected. These include, but are not limited to, weight

of domes, weight of towers and piping, effect of product in the partially filled

condition, accelerations and hull deflection. In addition, the local effect of

external or internal pressures or both shall be taken into account.

- P4 = external pressure due to head of water for

pressure vessels or part of pressure vessels on exposed decks; elsewhere

P4= 0.

6.4.15.3.2.4 Scantlings based on internal pressure shall be calculated

as follows:

The thickness and form of pressure-containing parts of pressure vessels,

under internal pressure, as defined in 6.4.9.3.3.1, including flanges, shall be

determined. These calculations shall in all cases be based on accepted pressure

vessel design theory. Openings in pressure-containing parts of pressure vessels

shall be reinforced in accordance with a recognized standard acceptable to the

Administration.

6.4.15.3.2.5 Stress analysis in respect of static and dynamic loads

shall be performed as follows:

- .1 pressure vessel scantlings shall be determined in accordance

with 6.4.15.3.2.1 to 6.4.15.3.2.4 and 6.4.15.3.3;

- .2 calculations of the loads and stresses in way of the supports

and the shell attachment of the support shall be made. Loads referred to in

6.4.9.2 to 6.4.9.5 shall be used, as applicable. Stresses in way of the supports

shall be to a recognized standard acceptable to the Administration. In special

cases a fatigue analysis may be required by the Administration; and

- .3 if required by the Administration, secondary stresses and

thermal stresses shall be specially considered.

6.4.15.3.3 Ultimate design condition

6.4.15.3.3.1 Plastic deformation

For type C independent tanks, the allowable stresses shall not exceed:

- σm ≤ f

- σL ≤ 1.5f

- σb ≤ 1.5f

- σL + σb ≤ 1.5f

- σm + σb ≤ 1.5f

- σm + σb + σg

≤ 3.0f

- σL + σb + σg

≤ 3.0f

where:

- σm = equivalent primary general membrane stress;

- σL = equivalent primary local membrane stress;

- σb = equivalent primary bending stress;

- σg = equivalent secondary stress; and

- f = the lesser of Rm/A or

Re/B,

- with Rm and Reas defined in

6.4.12.1.1.3. With regard to the stresses σm , σL,

σg and σb see also the

definition of stress categories in 6.4.15.2.3.6. The values A and B shall have

at least the following minimum values:

|

|

Nickel steels and carbon-manganese

steels

|

Austenitic steels

|

Aluminium alloys

|

| A

|

3

|

3.5

|

4

|

| B

|

1.5

|

1.5

|

1.5

|

6.4.15.3.3.2 Buckling criteria shall be as follows:

The thickness and form of pressure vessels subject to external pressure

and other loads causing compressive stresses shall be based on calculations using

accepted pressure vessel buckling theory and shall adequately account for the

difference in theoretical and actual buckling stress as a result of plate edge

misalignment, ovality and deviation from true circular form over a specified arc or

chord length.

6.4.15.3.4 Fatigue design condition

6.4.15.3.4.1 For type C independent tanks where the liquefied gas fuel

at atmospheric pressure is below minus 55°C, the Administration may require

additional verification to check their compliance with 6.4.15.3.1.1, regarding

static and dynamic stress depending on the tank size, the configuration of the tank

and arrangement of its supports and attachments.

6.4.15.3.4.2 For vacuum insulated tanks, special attention shall be made

to the fatigue strength of the support design and special considerations shall also

be made to the limited inspection possibilities between the inside and outer shell.

6.4.15.3.5 Accidental design condition

6.4.15.3.5.1 The tanks and the tank supports shall be designed for the

accidental loads and design conditions specified in 6.4.9.5 and 6.4.1.6.3, as

relevant.

6.4.15.3.5.2 When subjected to the accidental loads specified in 6.4.9.5,

the stress shall comply with the acceptance criteria specified in 6.4.15.3.3.1,

modified as appropriate taking into account their lower probability of occurrence.

6.4.15.3.6 Marking

The required marking of the pressure vessel shall be achieved by a

method that does not cause unacceptable local stress raisers.

6.4.15.4 Membrane tanks

6.4.15.4.1 Design basis

6.4.15.4.1.1 The design basis for membrane containment systems is that

thermal and other expansion or contraction is compensated for without undue risk of

losing the tightness of the membrane.

6.4.15.4.1.2 A systematic approach, based on analysis and testing, shall

be used to demonstrate that the system will provide its intended function in

consideration of the identified in service events as specified in 6.4.15.4.2.1.

6.4.15.4.1.3 A complete secondary barrier is required as defined in

6.4.3. The secondary barrier shall be designed according to 6.4.4.

6.4.15.4.1.4 The design vapour pressure P0 shall not normally

exceed 0.025 MPa. If the hull scantlings are increased accordingly and consideration

is given, where appropriate, to the strength of the supporting thermal insulation,

P0 may be increased to a higher value but less than 0.070 MPa.

6.4.15.4.1.5 The definition of membrane tanks does not exclude designs

such as those in which non-metallic membranes are used or where membranes are

included or incorporated into the thermal insulation.

6.4.15.4.1.6 The thickness of the membranes shall normally not exceed 10

mm.

6.4.15.4.1.7 The circulation of inert gas throughout the primary and the

secondary insulation spaces, in accordance with 6.11.1 shall be sufficient to allow

for effective means of gas detection.

6.4.15.4.2 Design considerations

6.4.15.4.2.1 Potential incidents that could lead to loss of fluid

tightness over the life of the membranes shall be evaluated. These include, but are

not limited to:

- .1 Ultimate design events:

- .1 tensile failure of membranes;

- .2 compressive collapse of thermal insulation;

- .3 thermal ageing;

- .4 loss of attachment between thermal insulation and hull

structure;

- .5 loss of attachment of membranes to thermal insulation

system;

- .6 structural integrity of internal structures and their

associated supporting structures; and

- .7 failure of the supporting hull structure.

- .2 Fatigue design events:

- .1 fatigue of membranes including joints and attachments to

hull structure;

- .2 fatigue cracking of thermal insulation;

- .3 fatigue of internal structures and their associated

supporting structures; and

- .4 fatigue cracking of inner hull leading to ballast water

ingress.

- .3 Accident design events:

- .1 accidental mechanical damage (such as dropped objects

inside the tank while in service);

- .2 accidental over pressurization of thermal insulation

spaces;

- .3 accidental vacuum in the tank; and

- .4 water ingress through the inner hull structure.

Designs where a single internal event could cause simultaneous or

cascading failure of both membranes are unacceptable.

6.4.15.4.2.2 The necessary physical properties (mechanical, thermal,

chemical, etc.) of the materials used in the construction of the liquefied gas fuel

containment system shall be established during the design development in accordance

with 6.4.15.4.1.2.

6.4.15.4.3 Loads, load combinations

Particular consideration shall be paid to the possible loss of tank

integrity due to either an overpressure in the interbarrier space, a possible vacuum

in the liquefied gas fuel tank, the sloshing effects, to hull vibration effects, or

any combination of these events.

6.4.15.4.4 Structural analyses

6.4.15.4.4.1 Structural analyses and/or testing for the purpose of

determining the ultimate strength and fatigue assessments of the liquefied gas fuel

containment and associated structures and equipment noted in 6.4.7 shall be

performed. The structural analysis shall provide the data required to assess each

failure mode that has been identified as critical for the liquefied gas fuel

containment system.

6.4.15.4.4.2 Structural analyses of the hull shall take into account the

internal pressure as indicated in 6.4.9.3.3.1. Special attention shall be paid to

deflections of the hull and their compatibility with the membrane and associated

thermal insulation.

6.4.15.4.4.3 The analyses referred to in 6.4.15.4.4.1 and 6.4.15.4.4.2

shall be based on the particular motions, accelerations and response of ships and

liquefied gas fuel containment systems.

6.4.15.4.5 Ultimate design condition

6.4.15.4.5.1 The structural resistance of every critical component,

sub-system, or assembly, shall be established, in accordance with 6.4.15.4.1.2, for

in-service conditions.

6.4.15.4.5.2 The choice of strength acceptance criteria for the failure

modes of the liquefied gas fuel containment system, its attachments to the hull

structure and internal tank structures, shall reflect the consequences associated

with the considered mode of failure.

6.4.15.4.5.3 The inner hull scantlings shall meet the regulations for

deep tanks, taking into account the internal pressure as indicated in 6.4.9.3.3.1

and the specified appropriate regulations for sloshing load as defined in

6.4.9.4.1.3.

6.4.15.4.6 Fatigue design condition

6.4.15.4.6.1 Fatigue analysis shall be carried out for structures inside

the tank, i.e. pump towers, and for parts of membrane and pump tower attachments,

where failure development cannot be reliably detected by continuous monitoring.

6.4.15.4.6.2 The fatigue calculations shall be carried out in accordance

with 6.4.12.2, with relevant regulations depending on:

- .1 the significance of the structural components with respect

to structural integrity; and

- .2 availability for inspection.

6.4.15.4.6.3 For structural elements for which it can be demonstrated by

tests and/or analyses that a crack will not develop to cause simultaneous or

cascading failure of both membranes, Cw shall be less than or

equal to 0.5.

6.4.15.4.6.4 Structural elements subject to periodic inspection, and

where an unattended fatigue crack can develop to cause simultaneous or cascading

failure of both membranes, shall satisfy the fatigue and fracture mechanics

regulations stated in 6.4.12.2.8.

6.4.15.4.6.5 Structural element not accessible for in-service

inspection, and where a fatigue crack can develop without warning to cause

simultaneous or cascading failure of both membranes, shall satisfy the fatigue and

fracture mechanics regulations stated in 6.4.12.2.9.

6.4.15.4.7 Accidental design condition

6.4.15.4.7.1 The containment system and the supporting hull structure shall be

designed for the accidental loads specified in 6.4.9.5. These loads need not be

combined with each other or with environmental loads.

6.4.15.4.7.2 Additional relevant accidental scenarios shall be determined based on a

risk analysis. Particular attention shall be paid to securing devices inside of

tanks.

6.4.16 Limit state design for novel concepts

6.4.16.1 Fuel containment systems that are of a novel configuration that cannot be

designed using section 6.4.15 shall be designed using this section and 6.4.1 to

6.4.14, as applicable. Fuel containment system design according to this section

shall be based on the principles of limit state design which is an approach to

structural design that can be applied to established design solutions as well as

novel designs. This more generic approach maintains a level of safety similar to

that achieved for known containment systems as designed using 6.4.15.

6.4.16.2 The limit state design is a systematic approach where each

structural element is evaluated with respect to possible failure modes related to

the design conditions identified in 6.4.1.6. A limit state can be defined as a

condition beyond which the structure, or part of a structure, no longer satisfies

the regulations.

6.4.16.3 For each failure mode, one or more limit states may be

relevant. By consideration of all relevant limit states, the limit load for the

structural element is found as the minimum limit load resulting from all the

relevant limit states. The limit states are divided into the three following

categories:

-

.1 Ultimate limit states (ULS), which correspond to the maximum

load-carrying capacity or, in some cases, to the maximum applicable strain

or deformation; under intact (undamaged) conditions.

-

.2 Fatigue limit states (FLS), which correspond to degradation

due to the effect of time varying (cyclic) loading.

-

.3 Accident limit states (ALS), which concern the ability of the

structure to resist accidental situations.

6.4.16.4 The procedure and relevant design parameters of the limit state

design shall comply with the Standards for the Use of limit state methodologies in

the design of fuel containment systems of novel configuration (LSD Standard), as set

out in the annex to part A-1.

6.5 Regulations for portable liquefied gas fuel tanks

6.5.1 The design of the tank shall comply with 6.4.15.3. The tank support (container